High-efficiency afterburning type compressed air energy storage system

A technology of compressed air energy storage and energy storage system, which is applied in the direction of steam engine device, liquid variable capacity machinery, variable capacity pump components, etc., which can solve the problem of high cost of heat accumulator hardware facilities, high equipment investment cost, and air throttling Problems such as pressure loss, to achieve the effect of easy realization of the combustion process, compact and reasonable structure, and reduced pressure parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

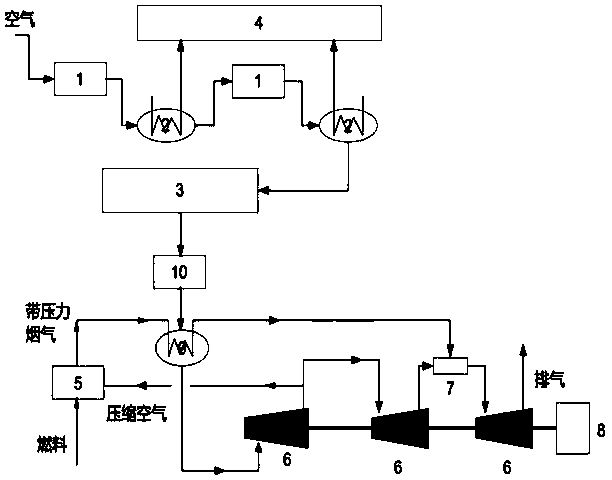

Embodiment 1

[0037] In this embodiment, the energy is stored during the low electricity price period at night, and the electric energy is released during the peak electricity price period during the day. see figure 1 , is the high-efficiency post-combustion compressed air energy storage system described in the present invention. The electric energy energy storage process is carried out at night when the electricity price is low, and the air compression unit 1 is driven by the cheap electric energy during the low electricity price to prepare high-pressure compressed air and store it in the gas storage. In space 3, the wave valley electric energy is transformed into the pressure energy of compressed air.

[0038] The trough electric energy drives multiple air compression units 1 to work. After the air is sucked into the air compression unit 1, the pressure increases, and the temperature of the air discharged from the air compression unit 1 increases. The heat carried by the compressed air is...

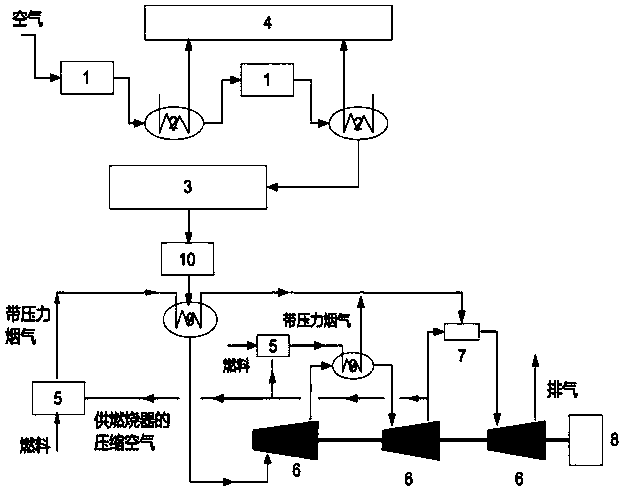

Embodiment 2

[0043] In this embodiment, the energy is stored during the low electricity price period at night, and the electric energy is released during the peak electricity price period during the day. The difference from Embodiment 1, such as figure 2 As shown, in the technical solution provided by Embodiment 2 of the present invention, two sets of burners 5 and two sets of second heat exchangers 9 are used, and the second heat exchanger 9 of the second set is arranged At the entrance of the second expander unit 6, the second burner 5 is arranged at the entrance of the second second heat exchanger 9, and the pressurized flue gas produced by the burner 5 flows through the two second heat exchangers respectively. The heaters 9 merge afterward. After the confluence, the two paths of pressurized flue gas pass through the gas mixing device 7, and are mixed with the pressurized flue gas discharged from the second expander unit 6 to form the same uniform working air flow, which enters the thi...

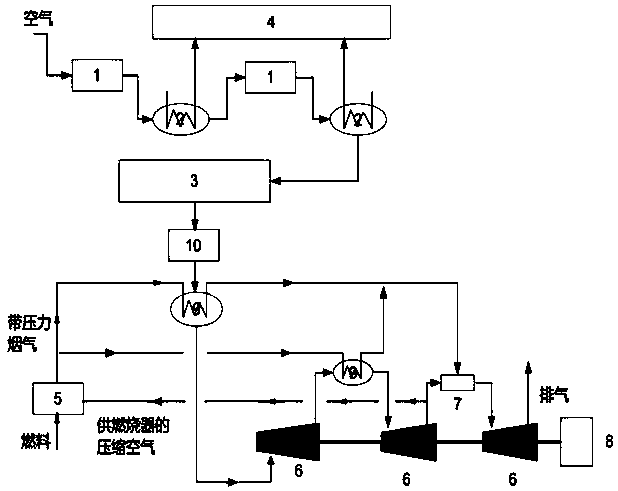

Embodiment 3

[0046] In this embodiment, the energy is stored during the low electricity price period at night, and the electric energy is released during the peak electricity price period during the day. like image 3 As shown, the difference compared with the second embodiment, a burner 5 is adopted in the third embodiment provided by the present invention, and the pressurized flue gas produced by the burner 5 can be divided into multiple streams and flow to different second converters respectively. Heater 9, multiple strands of pressurized flue gas are combined after the compressed air flow in the second heat exchanger 9 is heated, and the combined two-way flue gas passes through the gas mixing device 7 and is compressed with the compressed air discharged from the second expander unit 6. The air flow is mixed to form the same uniform work flow, which enters the third expander unit 6 to do work, output the shaft work, and discharge the exhaust air. The compressed air used by the combusto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com