Silicon, nitrogen and phosphorus efficient halogen-free flame retardant for fireproof flame-retardant coating, preparation method of flame retardant and application of flame retardant

A technology of fire-resistant and flame-retardant coatings and flame retardants, which is applied in the direction of fire-resistant coatings, rubber derivative coatings, polyurea/polyurethane coatings, etc., and can solve the problems of deteriorating mechanical properties of polymer materials, low flame-retardant efficiency, and large additions , to achieve good synergistic flame retardant effect, high flame retardant efficiency, and enhanced compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Silicon Nitrogen Phosphorus Efficient Halogen Free Flame Retardant

[0030] Step 1, KH560, triglycidyl isocyanurate and aminoimidazole are added into the reaction vessel, stirred and mixed evenly;

[0031] Step 2: Slowly add mono-isooctyl phosphate dropwise, keep the temperature below 40°C, and after the dropwise addition, raise the temperature to 65°C for 4 hours of reaction.

[0032] Wherein, the mass ratio of KH560, triglycidyl isocyanurate, aminoimidazole and monoisooctyl phosphate in the reaction is 4.5:1.5:0.6:1.1.

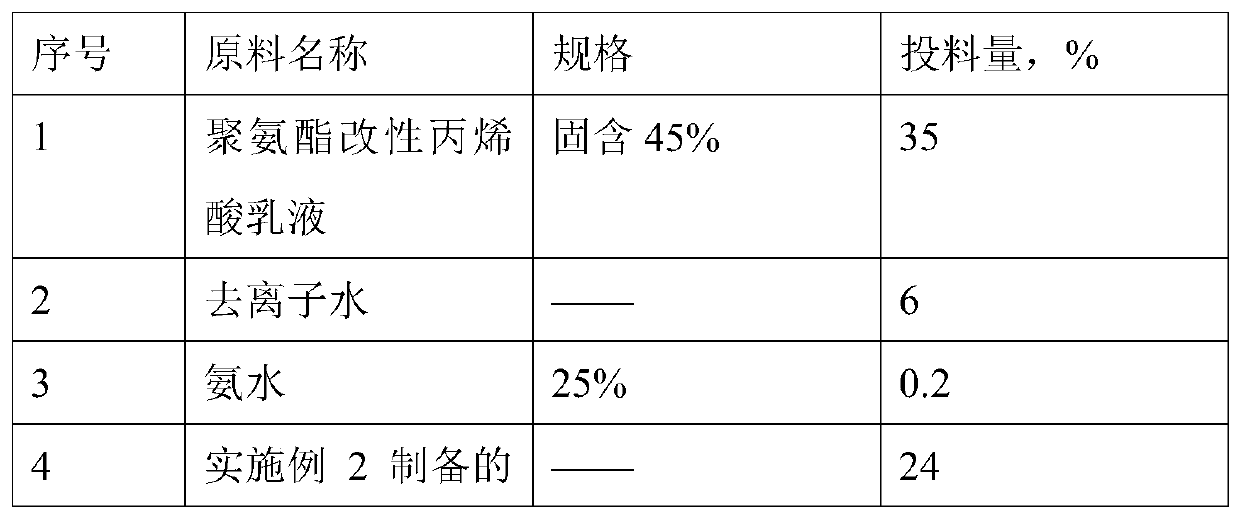

Embodiment 2

[0033] Example 2 Silicon Nitrogen Phosphorus Efficient Halogen Free Flame Retardant

[0034] Step 1, KH560 and triglycidyl isocyanurate are added to the reaction vessel, stirred and mixed evenly;

[0035] Step 2: Slowly add diisooctanoate phosphate dropwise, keeping the temperature below 40°C. After the dropwise addition, raise the temperature to 70°C for 3.5 hours.

[0036] The mass ratio of KH560, triglycidyl isocyanurate and diisocaprylic acid phosphate in the reaction is 2.0:1.5:0.3.

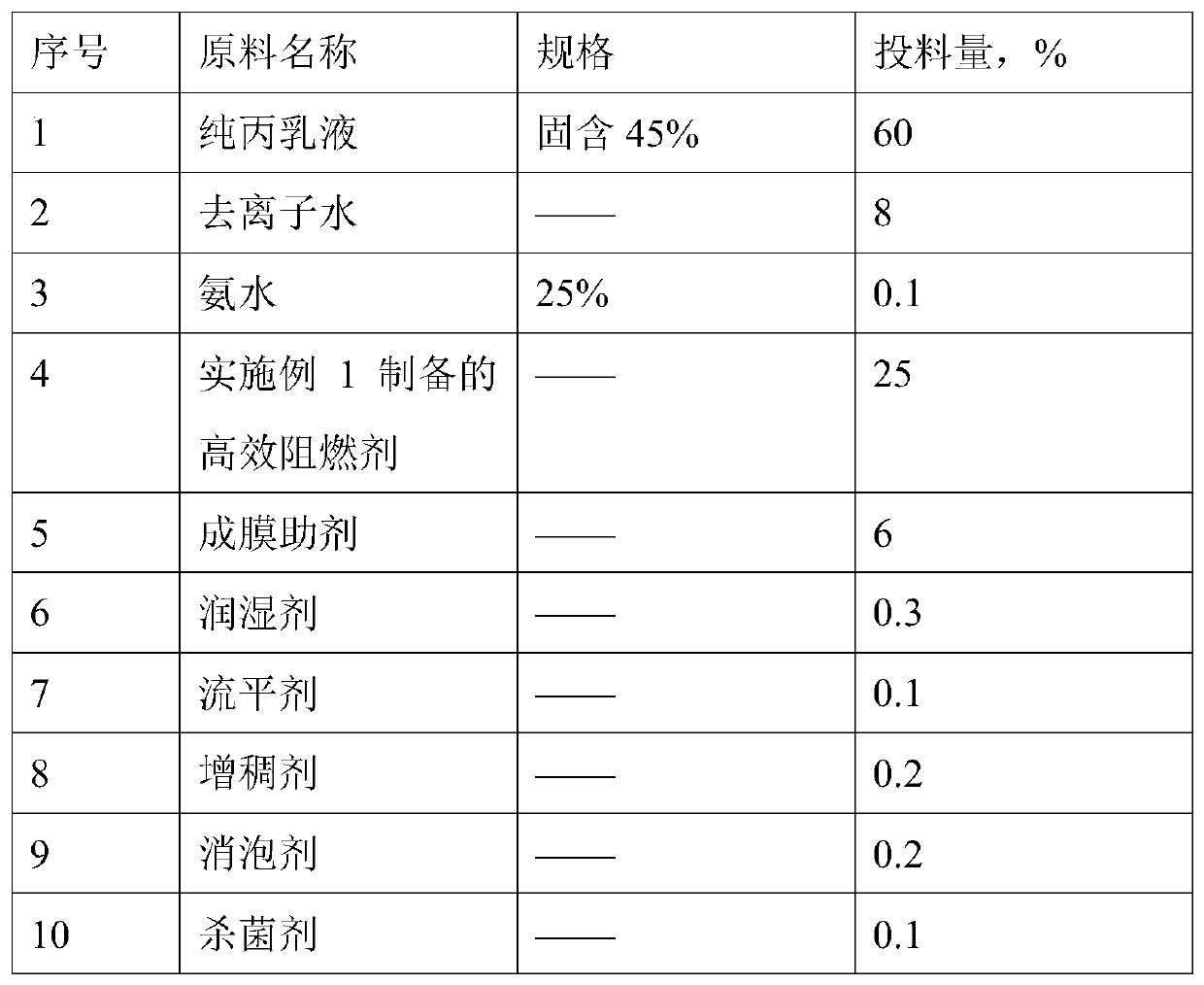

Embodiment 3

[0037] Example 3 Silicon Nitrogen Phosphorus Efficient Halogen Free Flame Retardant

[0038] Step 1, adding polyphosphoric acid and isopropanol into the reaction vessel, stirring and mixing evenly;

[0039] Step 2: Slowly add the mixture of KH560, aminoimidazole and triglycidyl isocyanurate dropwise, keep the temperature below 40°C, and then raise the temperature to 80°C for 3 hours after the dropwise addition.

[0040] The mass ratio of KH560, aminoimidazole, triglycidyl isocyanurate, polyphosphoric acid and isopropanol in the reaction is 0.8:0.3:2.6:0.4:0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com