Integrated control method for vacuum detection and filling of workpiece

A technology of vacuum detection and control method, which is applied in the direction of vacuum gauge, automatic packaging control, measurement of fluid pressure, etc. It can solve problems such as cumbersome operation and impact on product production efficiency, and achieve the goals of solving contradictions, efficient and accurate process switching, and improving accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

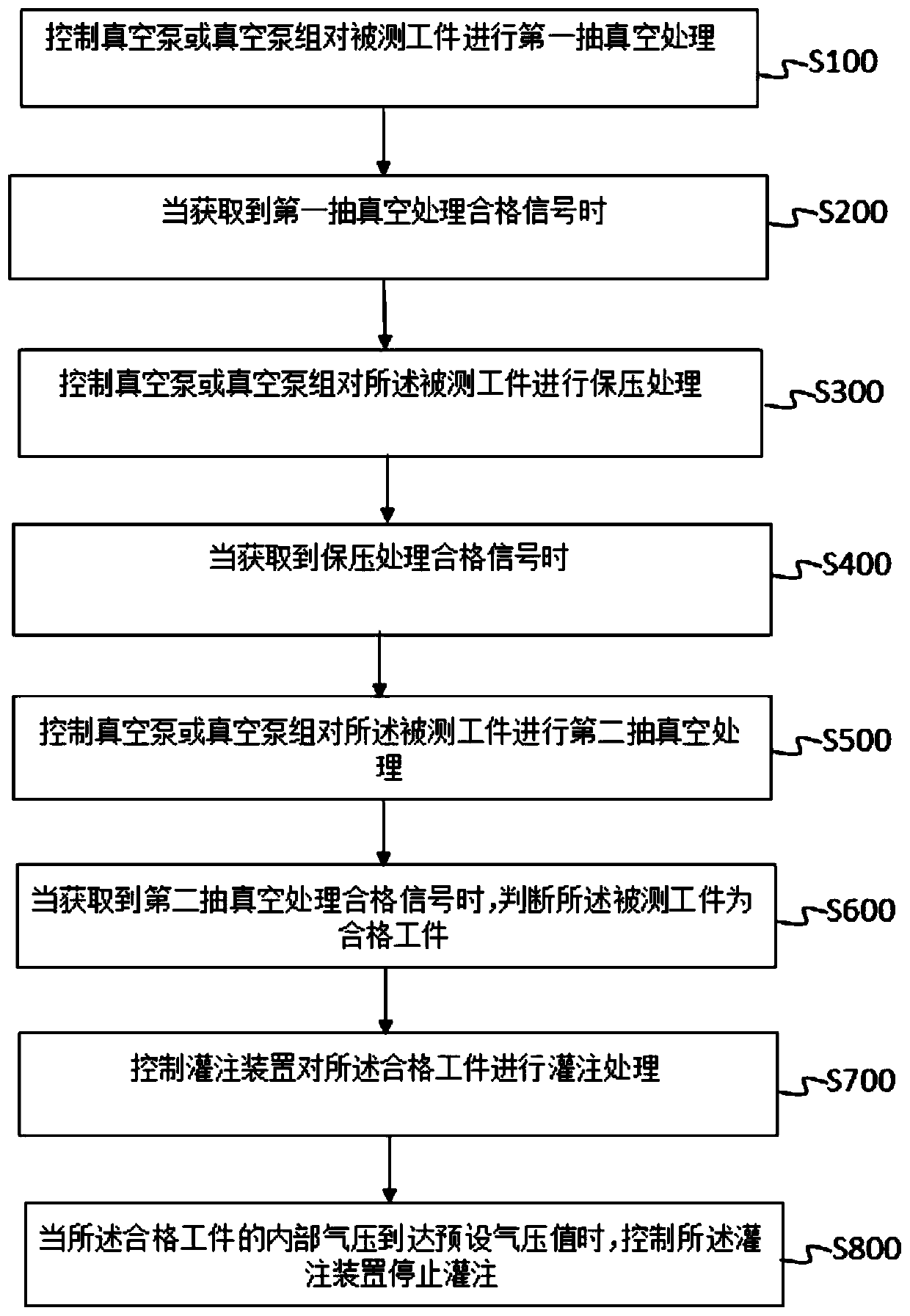

[0067] The present invention provides an integrated control method for workpiece vacuum detection and perfusion. In one embodiment of the present invention, as figure 1 shown, including:

[0068] S100: Control the vacuum pump or the vacuum pump group to perform the first vacuuming treatment on the workpiece under test;

[0069] S200: When the first vacuum pumping processing qualified signal is obtained;

[0070] S300: controlling a vacuum pump or a vacuum pump group to perform pressure maintaining on the workpiece to be tested;

[0071] S400: when the pressure holding processing qualified signal is obtained;

[0072] S500: controlling a vacuum pump or a vacuum pump group to perform a second v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com