A flexible chuck

A technology of loading and chucking, applied in the direction of chuck, expanding mandrel, etc., can solve problems such as inability to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

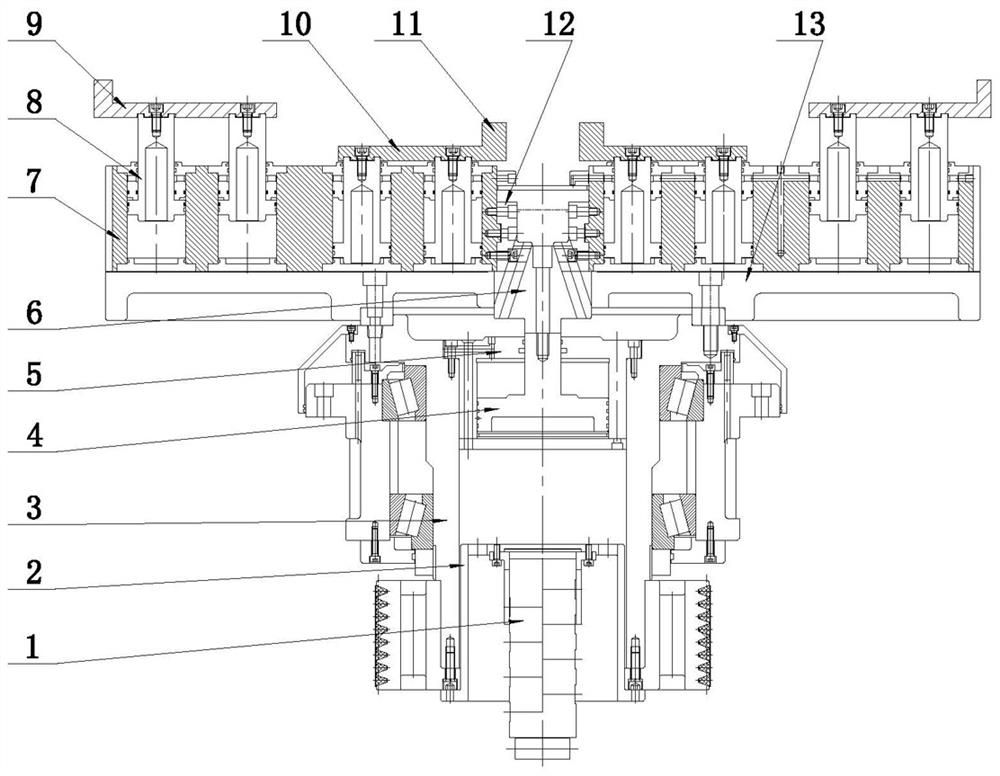

[0019] The present invention includes a main shaft 3, a turntable 13 is arranged on the top of the main shaft 3, and it is characterized in that: a central cylinder 5 is arranged inside the main shaft 3, and a central piston 4 connected with a wedge sleeve 6 is arranged inside the central cylinder 5; The wedge sleeve 6 is connected with the sliding body 7 through the guide slider 12 ; the sliding body 7 is provided with an inner claw 10 and an outer claw 9 through a lifting cylinder 8 .

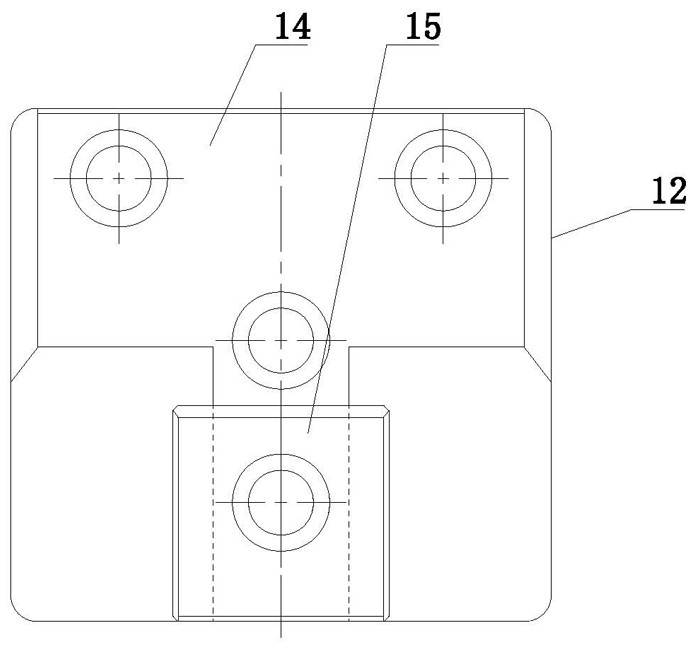

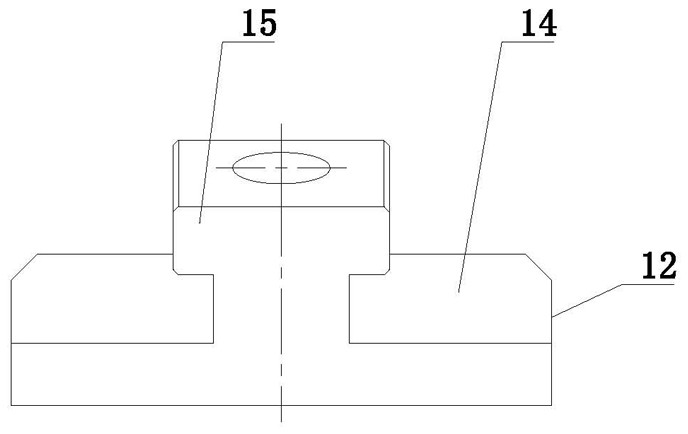

[0020] As a preferred solution of the present invention, the wedge sleeve 6 includes a wedge-shaped body, and the surface of the wedge-shaped body is provided with an inclined T-shaped groove 16; the guide slider 12 includes a connecting surface 14 connected with the sliding body 7, and the connecting surface 14 is provided with a T-shaped slider 15 that cooperates with the T-shaped groove 16 .

[0021] Further, the surface of the wedge-shaped body is provided with an inclined surface 17 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com