Method and system for on-line monitoring medicaments production mixing process

A technology of mixing process and medicine, applied in general control system, control/regulation system, program control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

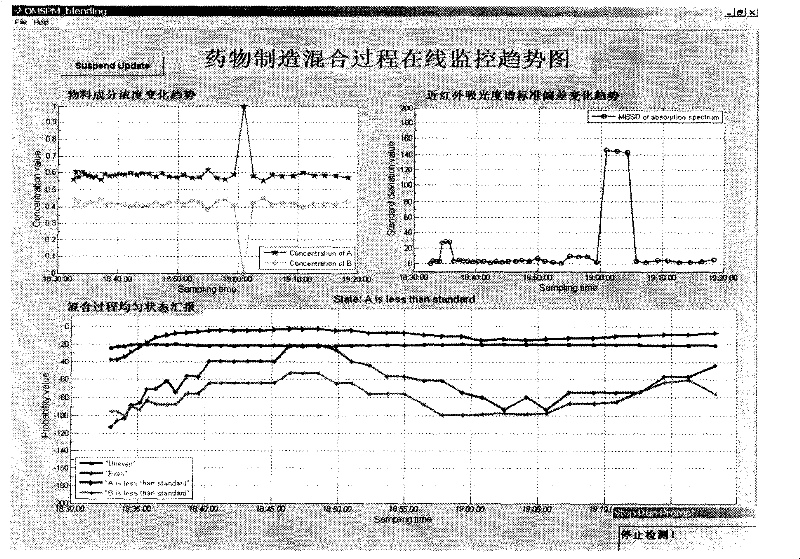

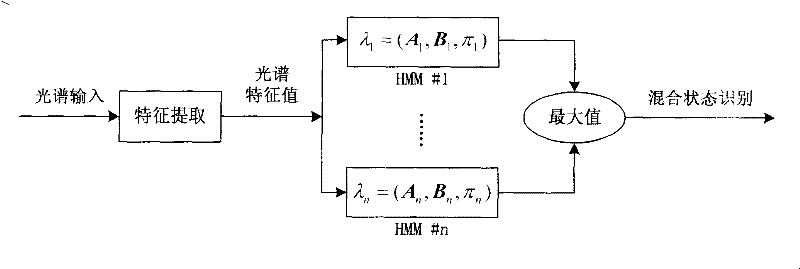

[0045] Various preferred embodiments of the present invention will be described in more detail below in conjunction with the accompanying drawings.

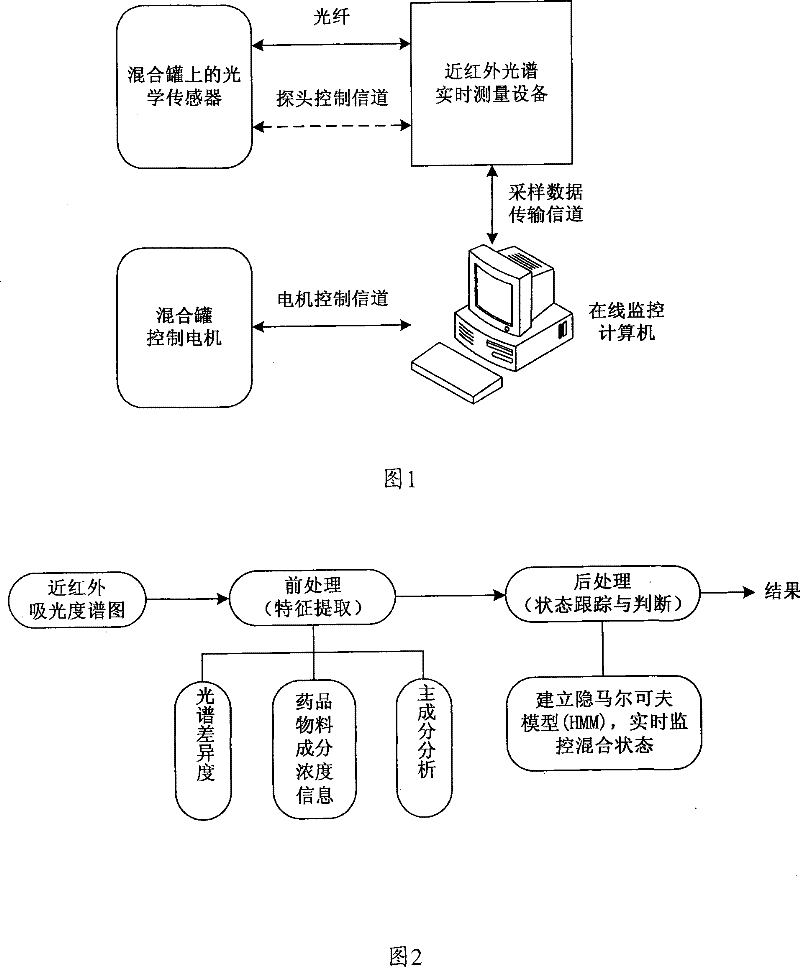

[0046] Application hardware system of the present invention such as figure 1 As shown, it includes an online monitoring computer, which controls and connects a near-infrared real-time measuring device, which is connected to an optical sensor through an optical fiber, and the optical sensor is arranged on a mixing tank, and the mixing process of the mixing tank is controlled by a Driven by a motor, the motor is controlled by the online monitoring computer.

[0047] The probe (optical sensor) of the near-infrared spectrum real-time measurement device is connected to the mixing tank through an optical fiber and a probe control channel. The optical probe can detect the near-infrared spectrum in the current state of the mixed material in real time and transmit it to the near-infrared spectrum. Infrared real-time measurement equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com