A kind of forging process of nitrogen-containing austenitic stainless steel

A technology of austenitic stainless steel and technology, which is applied in the field of metal forging technology, can solve the problems affecting the production progress and yield of materials, the production limitation of nitrogen-containing austenitic stainless steel, increasing the number of forging fires and production cycle, etc., so as to improve production The effects of processing efficiency, saving forging time, and reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

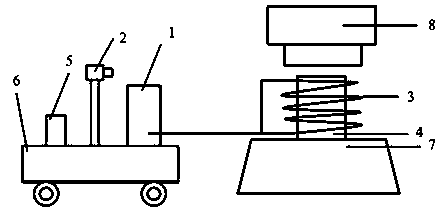

Image

Examples

Embodiment 1

[0024] Embodiment 1: The specific forging process of the present nitrogen-containing austenitic stainless steel is as follows.

[0025] The forging material is nitrogen-containing austenitic stainless steel electroslag ingot, size: Φ300mm×450mm. Carry out heat treatment on the billet, the process is: heating up at 300℃ / h to 1000℃, holding for 1h; then heating up at 100℃ / h to 1150℃, holding for 15h; out of the furnace and air cooling. Put it into the heating furnace before the forging press, raise the temperature to 1160 ° C with the furnace, and keep it warm for 5 hours to ensure that the billet is heated through.

[0026] Preparatory work before forging, equipment and circuit inspection. According to the blank forging requirements, set the temperature range on the temperature control valve as 950-1170°C. During the initial forging, induction coils are used to preheat the base of the forging press to 150°C. At the beginning of forging, the temperature measuring device monit...

Embodiment 2

[0028] Embodiment 2: The specific forging process of the present nitrogen-containing austenitic stainless steel is as follows.

[0029] The forging material is a nitrogen-containing austenitic stainless steel forging blank, and its size is 150mm×150mm×200mm. Carry out heat treatment on the billet, the process is as follows: heat up at 250°C / h to 1020°C, hold for 1h; then heat up at 120°C / h to 1150°C, hold for 10h; leave the furnace and air cool. Put it into the heating furnace before the forging press, raise the temperature to 1150 ° C with the furnace, and keep it warm for 10 hours to ensure that the billet is thoroughly heated.

[0030] Preparatory work before forging, equipment and circuit inspection. According to the blank forging requirements, set the temperature range on the temperature control valve as 950-1170°C. During the initial forging, induction coils are used to preheat the base of the forging press to 200°C. At the beginning of forging, the temperature measur...

Embodiment 3

[0032] Embodiment 3: The specific forging process of the present nitrogen-containing austenitic stainless steel is as follows.

[0033] The forging material is nitrogen-containing austenitic stainless steel non-vacuum ingot, size: Φ220mm×200mm. Carry out heat treatment on the billet, the process is as follows: heating up at 220℃ / h to 1000℃, holding for 1.5h; then heating up at 130℃ / h to 1160℃, holding for 12h; out of the furnace and air cooling. Put it into the heating furnace before the forging press, raise the temperature to 1150 ° C with the furnace, and keep it warm for 8 hours to ensure that the billet is heated through.

[0034]Preparatory work before forging, equipment and circuit inspection. According to the blank forging requirements, set the temperature range on the temperature control valve as 950-1170°C. During the initial forging, induction coils are used to preheat the base of the forging press to 180°C. At the beginning of forging, the temperature measuring d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com