Construction method and device of multi-spraying-head flow control model

A technology of flow control and construction method, which is applied in the direction of flow control using electric devices, etc., and can solve the problems that the flow control model of the nozzle is not enough to apply to the working scene of multiple nozzles, and cannot be corrected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

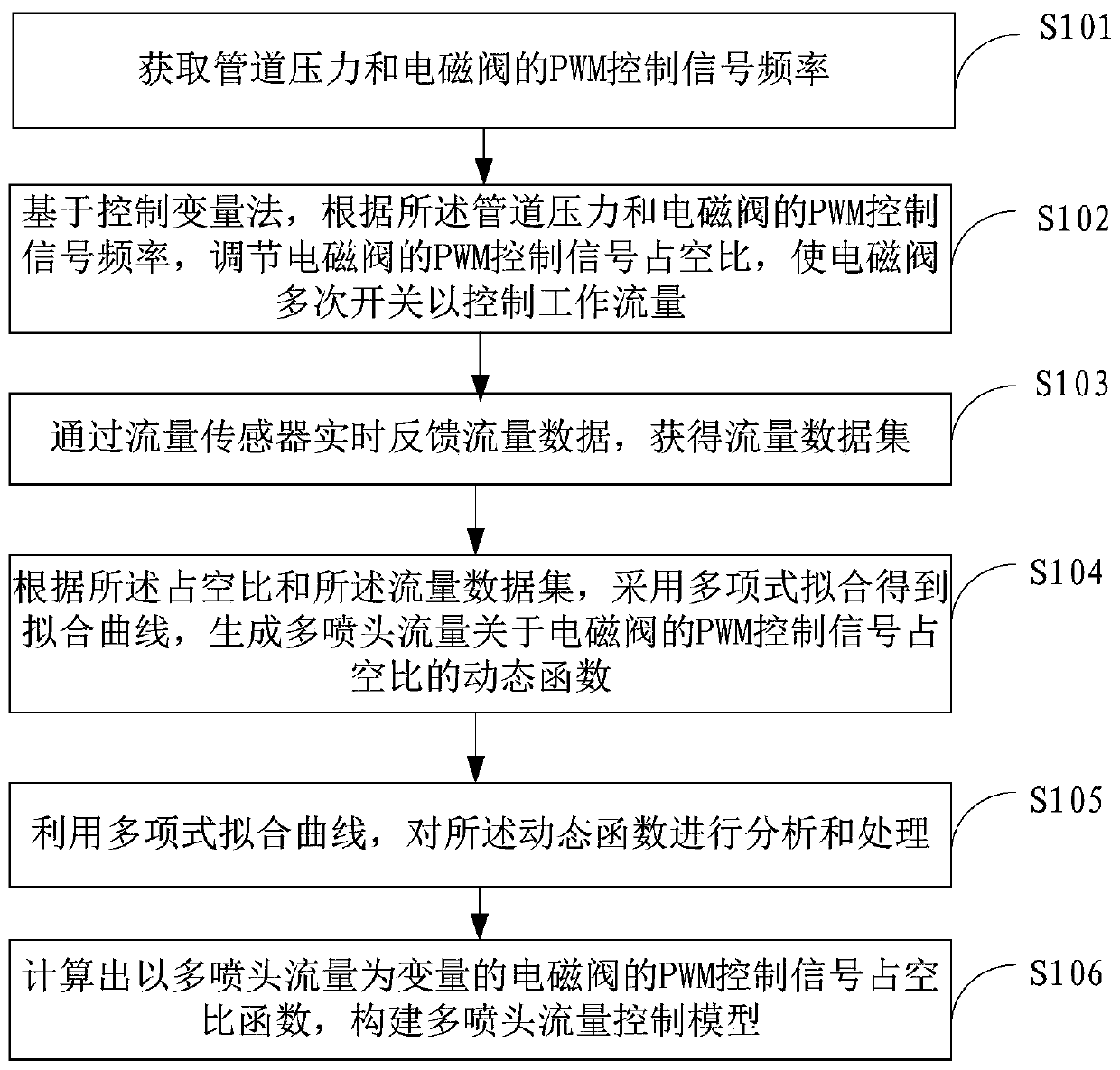

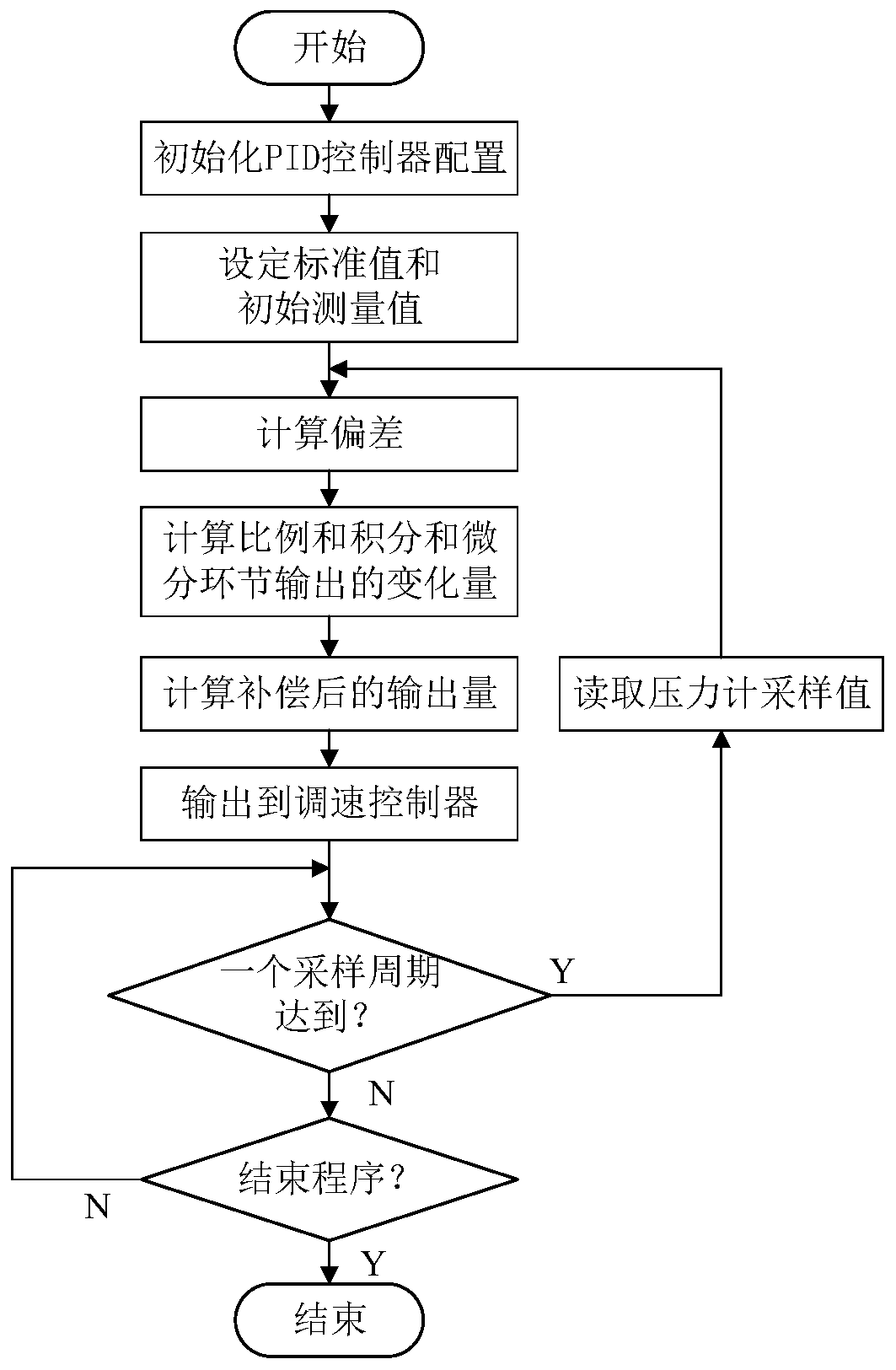

Method used

Image

Examples

Embodiment 1

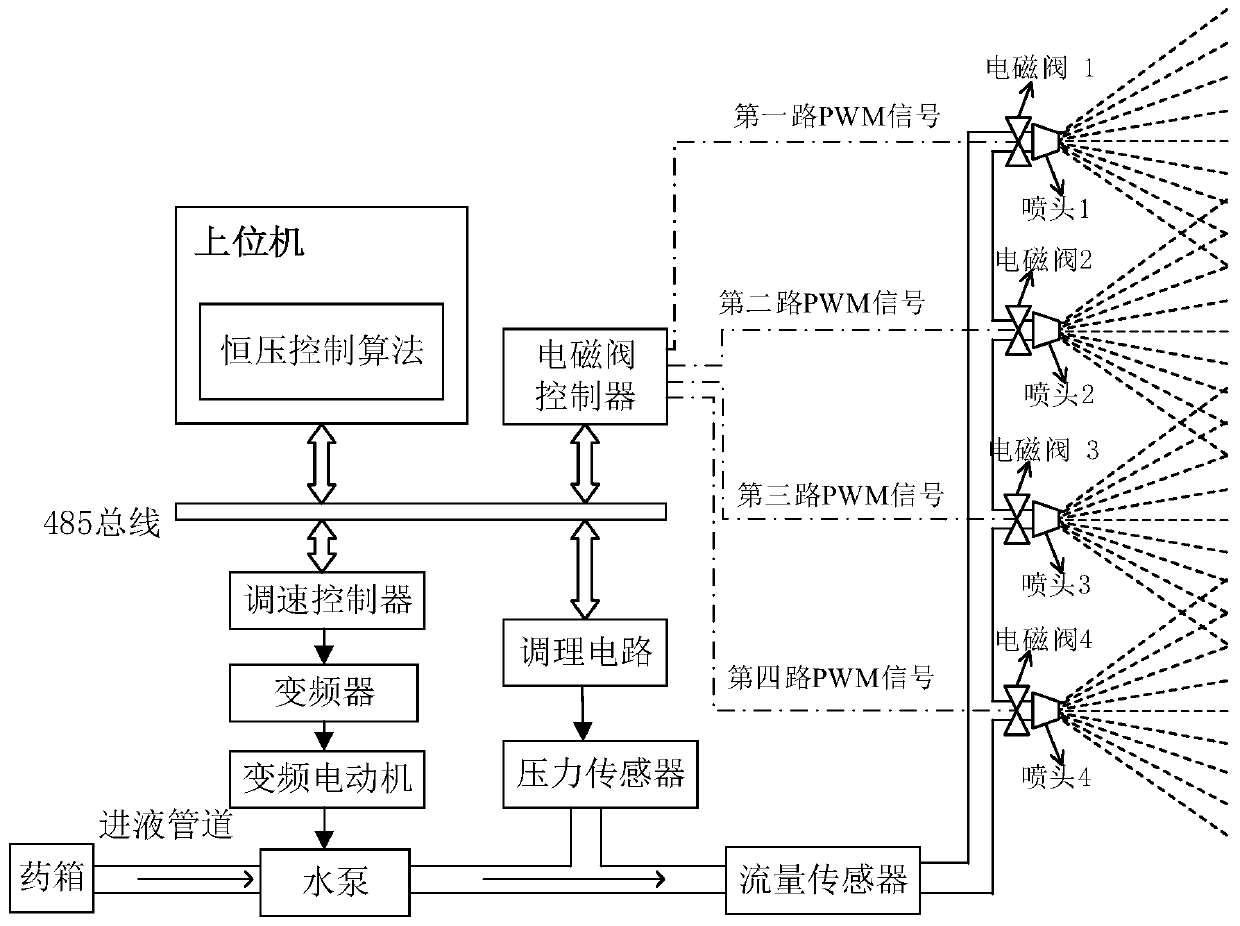

[0104] For example, a fine mist hollow cone nozzle with a fog cone angle of 80° is used; a total of 4 nozzles are used, the working pressure is 0.4-0.5MPa, and the corresponding flow range is 1.82-2.03L / min. If the 4 nozzles are turned on at the same time, the total The flow rate can reach up to 8.12L / min. Working pressure: The maximum working pressure of the variable spray device is 0.5MPa. In order to improve the reliability of the control, a solenoid valve with a working pressure exceeding 0.5MPa should be selected. A direct-acting solenoid valve is selected to work at a higher switching frequency. The variable spray device uses a total of 4 nozzles, and each nozzle is individually controlled by a 2-point solenoid valve.

[0105] Using the above test platform, the user interface provided by the PC host computer can adjust the experimental parameters in real time, and set the frequency and duty cycle of the control signal output by the solenoid valve controller. The PWM co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com