Ramjet generator for suction and exhaustion pipes

A generator and exhaust pipe technology, applied in exhaust devices, machines/engines, combustion air/combustion-air treatment, etc., can solve the problem of difficulty in increasing air supply, air flow rate and fuel mixing ratio, and no rapid exhaust gas discharge. and other problems, to achieve the effect of improving intake and exhaust efficiency, simple installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The ram generator of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0048] In the following description of the present invention, a detailed description of well-known functions or constructions related to the present invention will not be provided so as not to obscure the description of the present invention with unnecessary detail.

[0049] The terms described below are set in consideration of the functions of the present invention and may be changed according to the manufacturer's intention or use, so the definitions should be based on the entire specification.

[0050] The invention is logically described below with reference to the accompanying drawings.

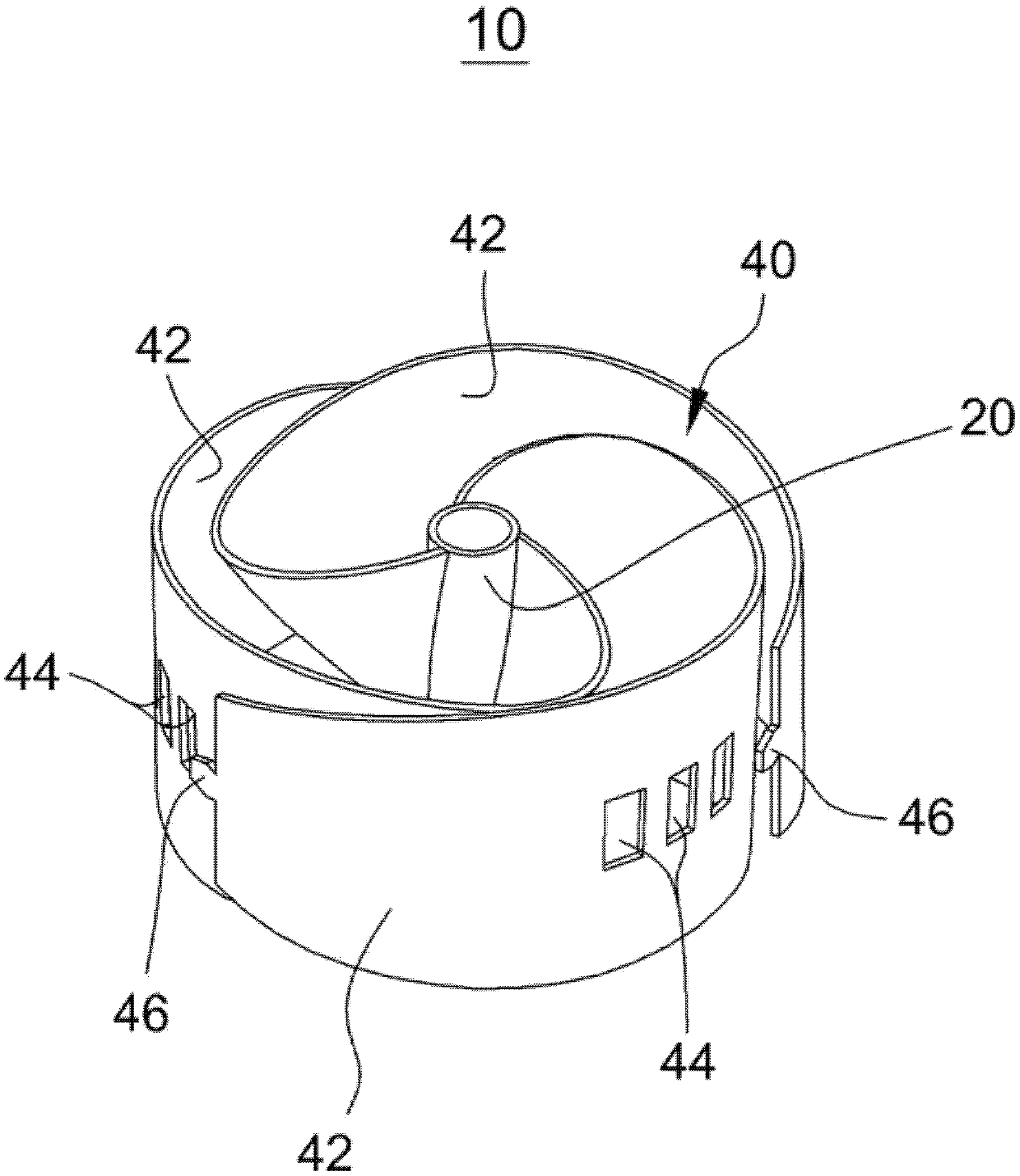

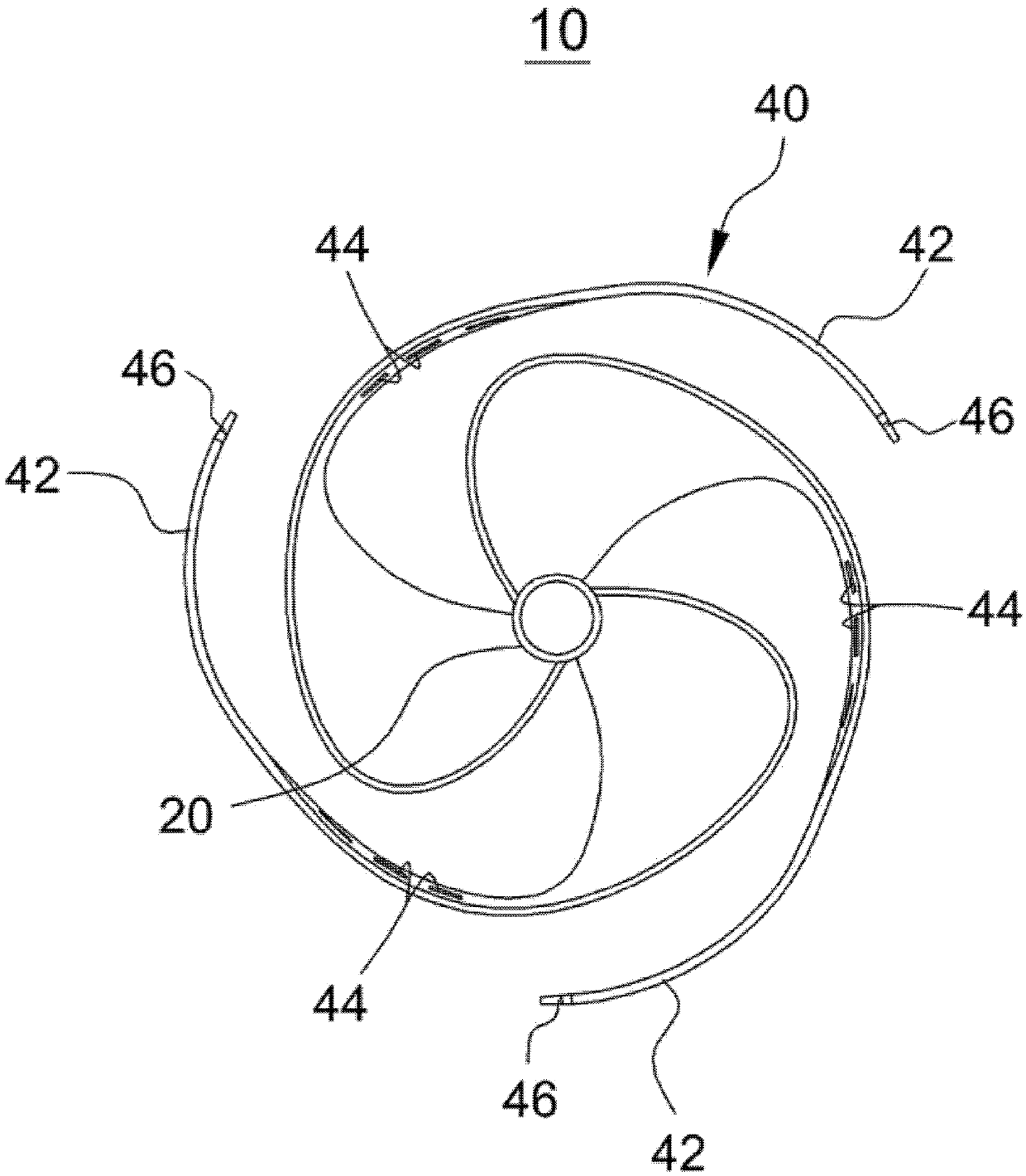

[0051] figure 1 is a perspective view of a punch generator according to an exemplary embodiment of the present disclosure, figure 2 Yes figure 1 The front view of the blade shown before assembly, image 3 Yes figure 1 A front view of the blade shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com