Superhydrophobic conductive composite fabric with electromagnetic shielding performance and preparation method thereof

A composite fabric and electromagnetic shielding technology, which is applied in the fields of magnetic field/electric field shielding, electrical components, textiles and papermaking, etc., can solve the fundamental problems of silver-based electromagnetic shielding materials, the decline in conductivity and electromagnetic interference shielding performance, and the metal is easy to be damaged Oxidation and even corrosion problems, to achieve excellent electromagnetic shielding performance, excellent super-hydrophobic performance, and short time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

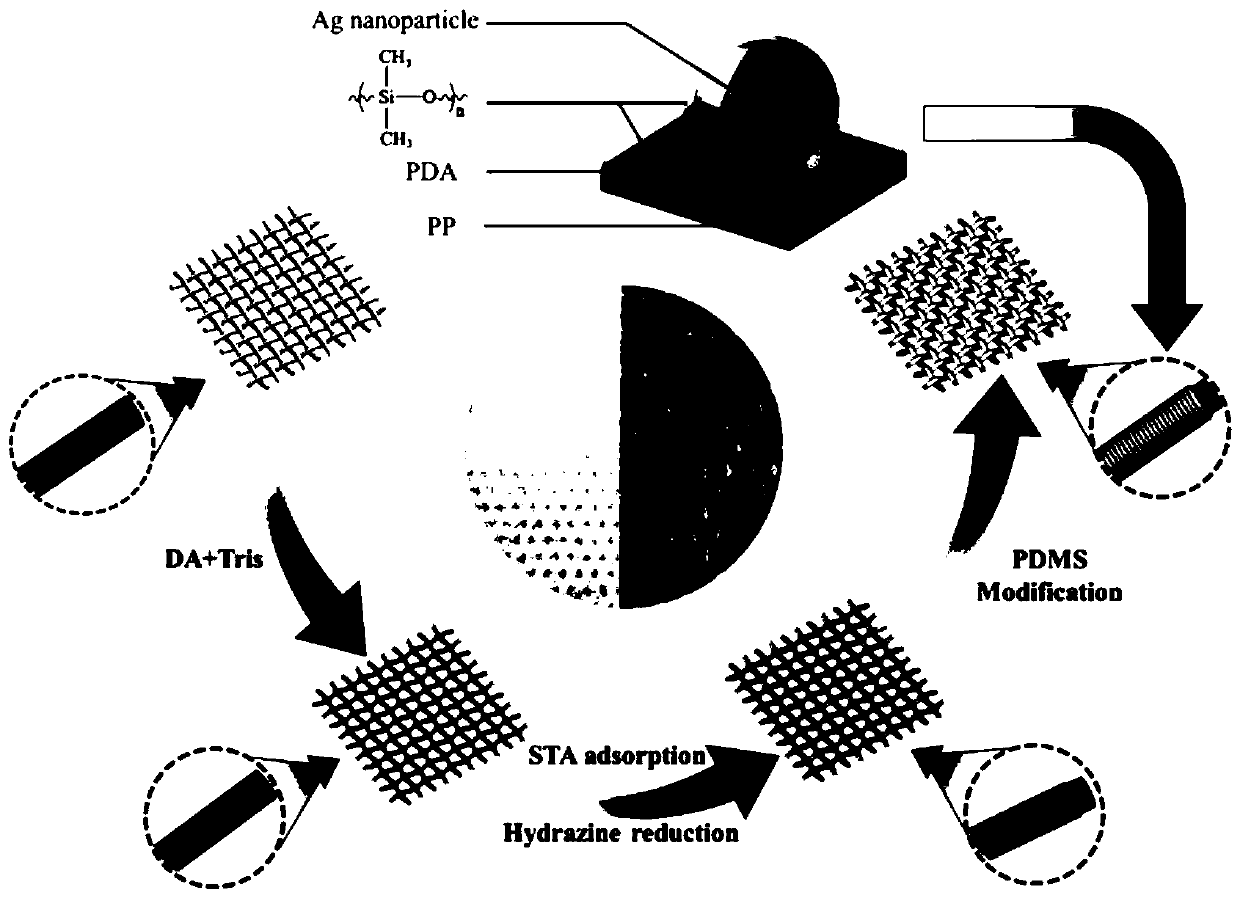

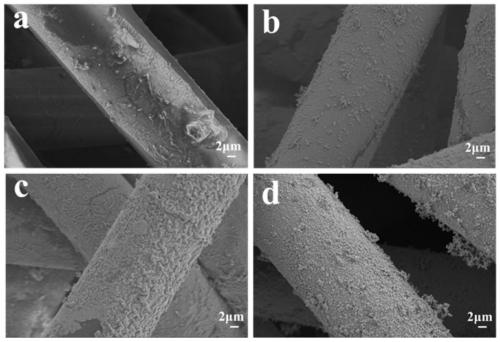

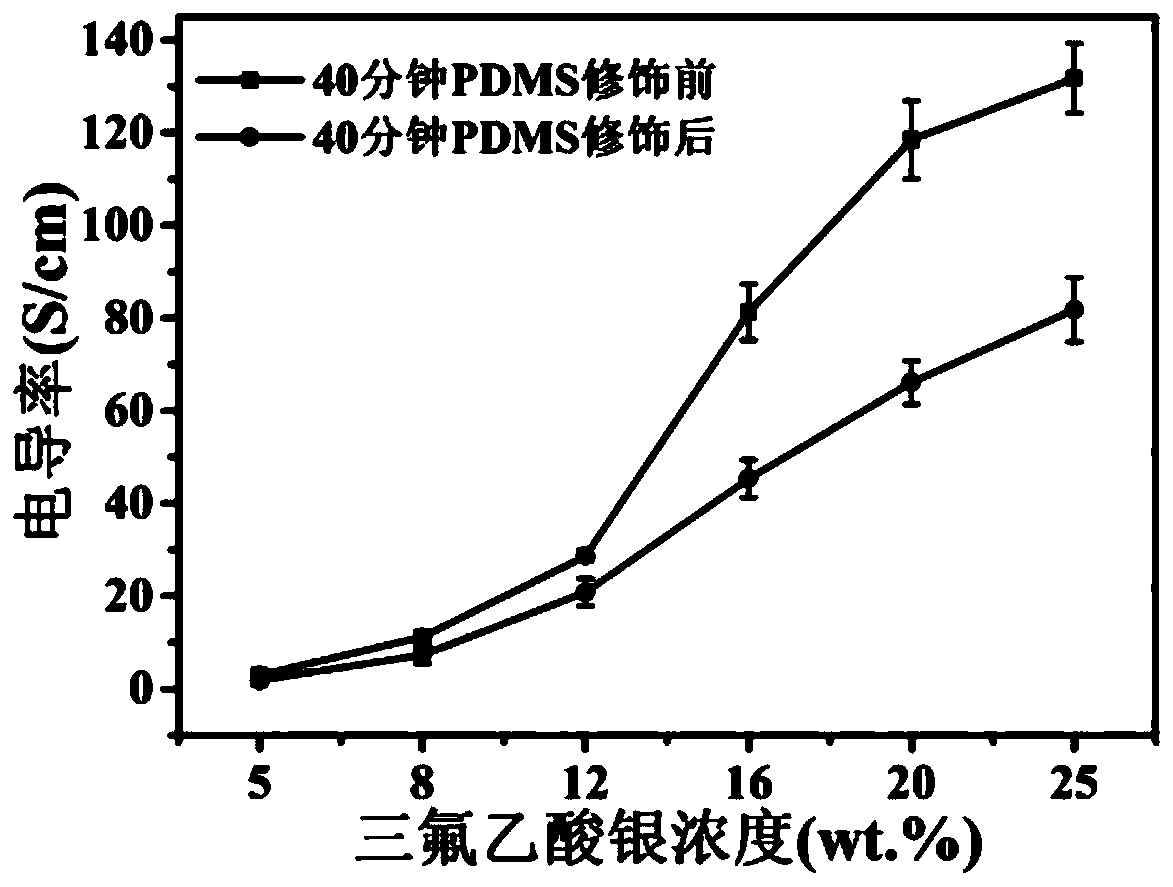

[0030] (1) Weigh 0.4 g of dopamine, 0.24 g of tris (Tris), and 200 g of distilled water. Dissolve dopamine and Tris in water, cut a commercially purchased PP non-woven fabric into 2cm×2cm and soak it, stir it magnetically for 12 hours, take it out, wash it and dry it in an oven at 60°C. Next, 1.5 g of silver trifluoroacetate was dissolved in 6 g of ethanol to prepare a 20 wt.% STA solution. Soak the dried PP non-woven fabric in silver trifluoroacetate solution for 40 minutes, take it out and reduce it with 50 wt.% hydrazine hydrate solution for 30 minutes. The reduced conductive fabric was washed with distilled water and dried in an oven at 40°C. Weigh 0.1g polydimethylsiloxane (PDMS) and 0.01g curing agent, and dissolve them in 9.9g n-heptane, the mass fraction of PDMS is 1%. The dried conductive composite fabric was placed in the PDMS solution for 40 minutes, and then cured at 80° C. for 1 hour to obtain a superhydrophobic conductive composite fabric. The microscopic morp...

Embodiment 2

[0034] (1) Weigh 0.4 g of dopamine, 0.24 g of tris (Tris), and 200 g of distilled water. Dissolve dopamine and Tris in water, cut a commercially purchased PP non-woven fabric into 2cm×2cm and soak it, stir it magnetically for 12 hours, take it out, wash it and dry it in an oven at 60°C. Next, 1.5 g of silver trifluoroacetate was dissolved in 4.5 g of ethanol to prepare a 25 wt.% STA solution. Soak the dried PP non-woven fabric in silver trifluoroacetate solution for 40 minutes, take it out and reduce it with 50 wt.% hydrazine hydrate solution for 30 minutes. The reduced conductive fabric was washed with distilled water and dried in an oven at 40°C. Weigh 0.1g polydimethylsiloxane (PDMS) and 0.01g curing agent, and dissolve them in 9.9g n-heptane, the mass fraction of PDMS is 1%. The dried conductive composite fabric was placed in the PDMS solution for 40 minutes, and then cured at 80° C. for 1 hour to obtain a superhydrophobic conductive composite fabric. The microscopic mo...

Embodiment 3

[0039] This embodiment is basically the same as Embodiment 2, the only difference is that the soaking time of 1wt.% PDMS is shortened to 20 minutes. Specifically: weigh 0.4 g of dopamine, 0.24 g of tris (Tris), and 200 g of distilled water. Dissolve dopamine and Tris in water, cut a commercially purchased PP non-woven fabric into 2cm×2cm, soak it for 12h with magnetic stirring, and then take it out, wash it and dry it in an oven at 60°C. Next, 1.5 g of silver trifluoroacetate was dissolved in 4.5 g of ethanol to prepare a 25 wt.% STA solution. Soak the dried PP non-woven fabric in silver trifluoroacetate solution for 40 minutes, and then take it out and reduce it with 50 wt.% hydrazine hydrate solution for 30 minutes. The reduced conductive fabric was washed with distilled water and dried in an oven at 40°C. Weigh 0.1g polydimethylsiloxane (PDMS) and 0.01g curing agent, and dissolve them in 9.9g n-heptane, the mass fraction of PDMS is 1%. The dried conductive composite fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com