Process for preparing halohydrins

A technology of halogenated alcohols and hydrogen halides, which is applied in the field of preparation of halogenated alcohols, can solve the problems of uneven treatment of deactivators, high solid content of the treatment system, and inability to realize directional and efficient titanium supplementation, and achieve mild reaction conditions and high raw material The effect of high conversion rate and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

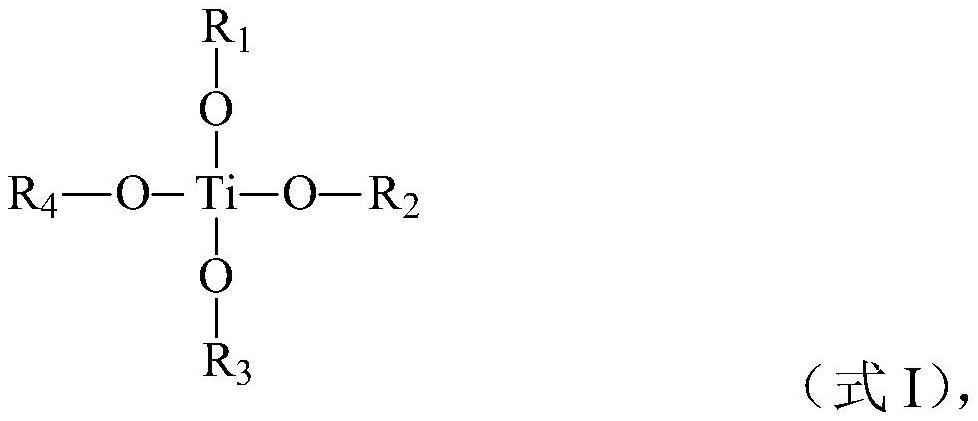

[0049] The preparation method of TS-1 molecular sieve is: the tetrapropyl ammonium hydroxide (TPAOH, 20%, purchased from U.S. Aldrich Company) solution of about 3 / 4 amount is added in tetraethyl orthosilicate (TEOS) solution, Obtain a liquid mixture with a pH of about 13, and then add a required amount of n-butyl titanate [Ti(OBu) dropwise to the obtained liquid mixture under vigorous stirring. 4 ] in anhydrous isopropanol solution, and after stirring for 15 minutes, a clear liquid was obtained. Finally, the remaining TPAOH was slowly added to the clear liquid, and stirred at 348-353K for about 3 hours to obtain a chemical composition of 0.03TiO 2 : SiO 2 :0.36TPA:35H 2 The sol of O was then crystallized at 443K for 3 days, and then the obtained solid was filtered, washed with distilled water, dried at 373K for 5 hours, and then calcined at 823K for 10 hours to obtain a molecular sieve sample. Wherein, the consumption of TEOS is 42g, the consumption of TPAOH is 73g, Ti(OBu) ...

Embodiment 1

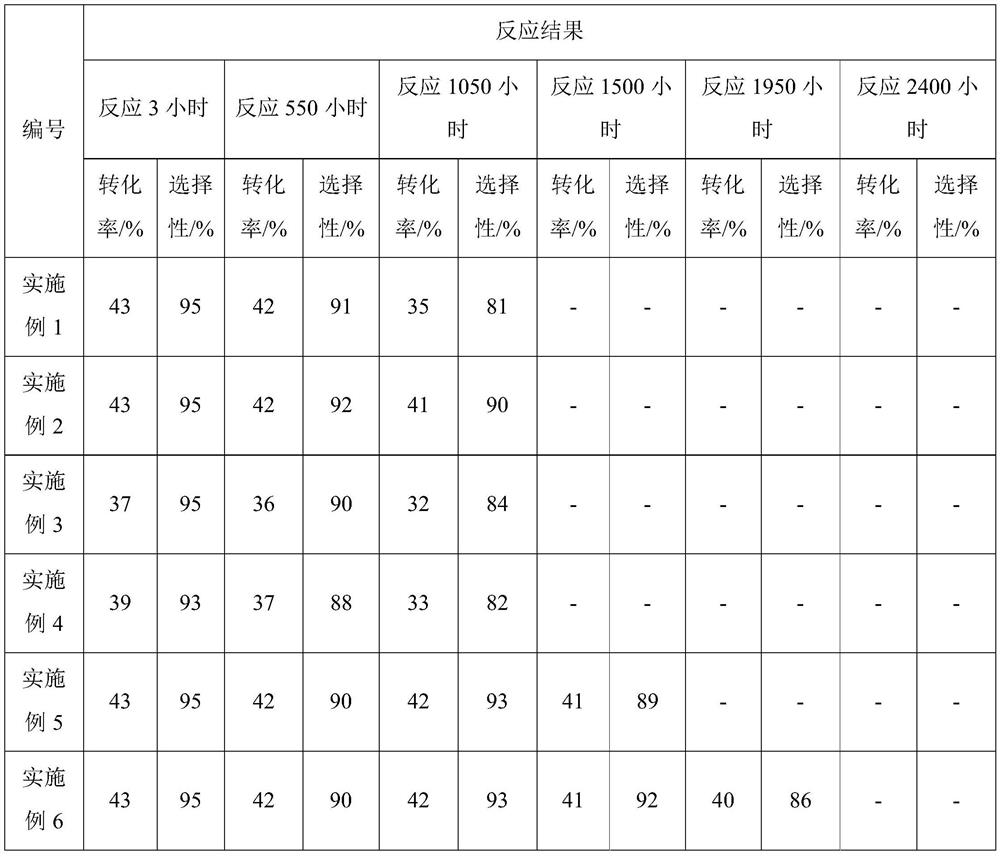

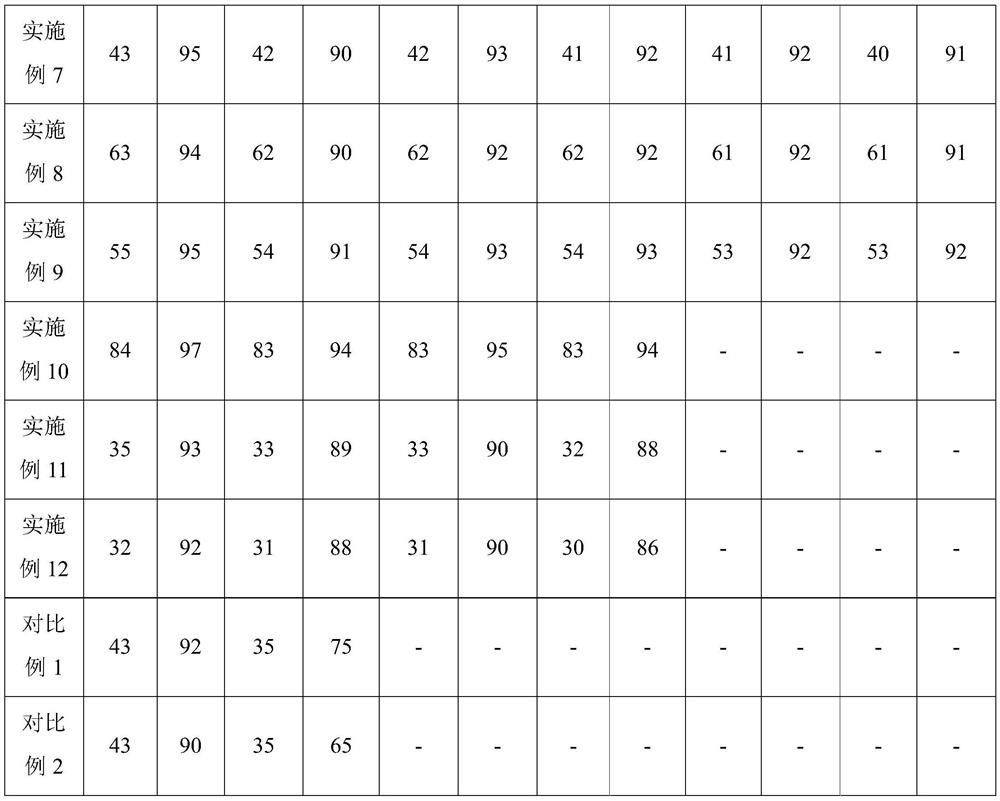

[0055] The TS-1 molecular sieve catalyst is packed in a fixed bed reactor to form a TS-1 molecular sieve catalyst bed. Hydrogen peroxide, polymaleic anhydride (weight average molecular weight 5000) and water were mixed to form a liquid mixture. Then the liquid mixture, allyl chloride, and hydrochloric acid (37% aqueous solution) are passed into a fixed-bed reactor at the same time to contact and react with the TS-1 molecular sieve catalyst bed. Among them, among the reaction raw materials, allyl chloride: H 2 o 2 : Water (molar ratio) is 1:1.3:40, H 2 o 2 : HCl (molar ratio) is 1:1.5, chloropropene: polymaleic anhydride (weight ratio) is 1:0.008. The material weight hourly space velocity in the fixed bed reactor is 80h -1 , the catalyst bed temperature was 40°C, and the reaction was carried out continuously. During the reaction, the composition of the product at the outlet of the reactor was monitored by gas chromatography. The analysis results are shown in Table 1.

Embodiment 2

[0057] The TS-1 molecular sieve catalyst is packed in a fixed bed reactor to form a TS-1 molecular sieve catalyst bed. Hydrogen peroxide, polymaleic anhydride (weight average molecular weight 5000), tetrabutyl titanate and water were mixed to form a liquid mixture. Then the liquid mixture, allyl chloride, and hydrochloric acid (37% aqueous solution) are passed into a fixed-bed reactor at the same time to contact and react with the TS-1 molecular sieve catalyst bed. Among them, among the reaction raw materials, allyl chloride: H 2 o 2 : Water (molar ratio) is 1:1.3:40, H 2 o 2 : HCl (molar ratio) is 1:1.5, propylene chloride: polymaleic anhydride (weight ratio) is 1:0.008, polymaleic anhydride: tetrabutyl titanate (weight ratio) is 1:0.02. The material weight hourly space velocity in the fixed bed reactor is 80h -1 , the catalyst bed temperature was 40°C, and the reaction was carried out continuously. During the reaction, the composition of the product at the outlet of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com