Alkali-metal-modified carbon-based catalyst used for desulfurization and denitrification and production method and application thereof

A carbon-based catalyst, desulfurization and denitrification technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve the problems of easy agglomeration, uneven dispersion of active coke, and lack of dispersion Measures and other issues to achieve the effect of avoiding agglomeration, improving reactivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention and its effects will be further described below through specific examples. The following examples are only used to illustrate the content of the present invention, and are not intended to limit the protection scope of the present invention. Applying the idea of the present invention to make simple changes to the present invention is within the scope of protection of the present invention.

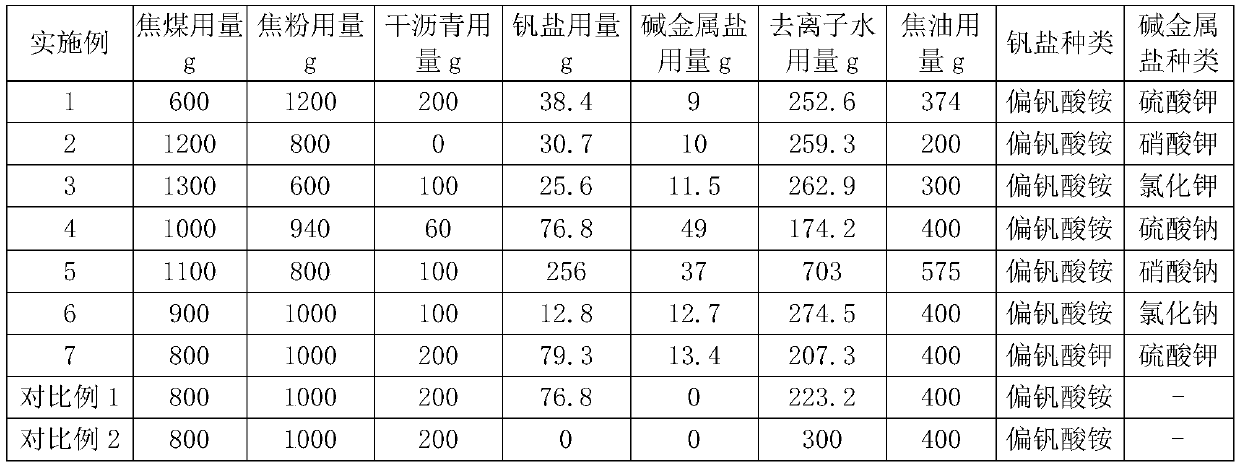

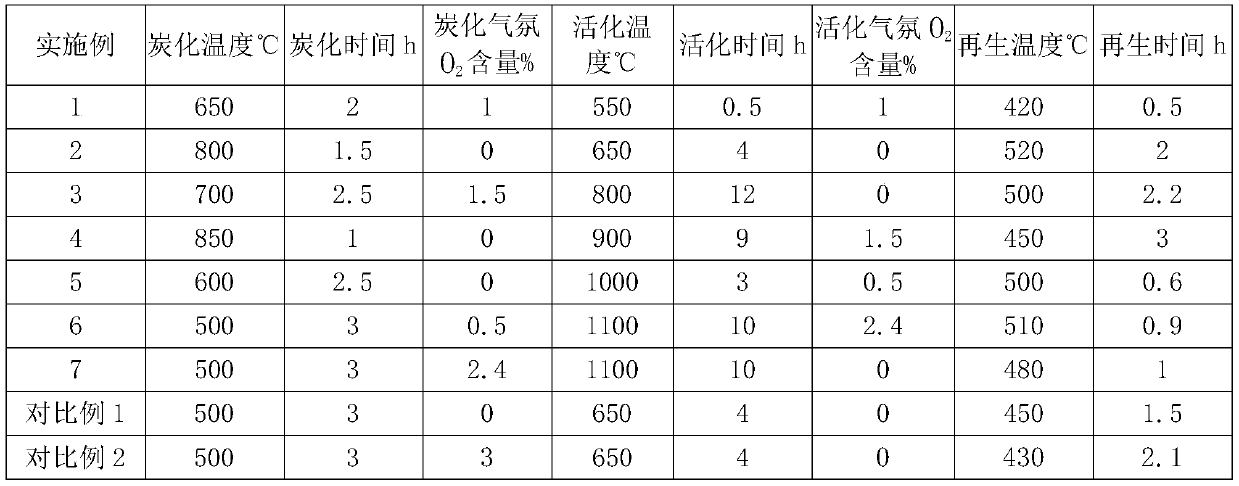

[0032] The preparation method of the desulfurization and denitration carbon-based catalyst of embodiment 1-7 is as follows:

[0033] (1) Preparation of coal powder: coking coal, coke powder, and dry asphalt are crushed, mixed and pulverized to a particle size of 200 mesh;

[0034] (2) Manufacture of coal paste: Add the prepared coal powder, coal tar, vanadium-containing salt and alkali metal salt solution into a kneader, stir and knead evenly to make coal paste.

[0035] (4) Forming and granulation: forming and granulating the coal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com