Production process of soft emulsifying paste for bread

A production process and technology of emulsifying paste, which is applied in the field of food additives for bread processing, can solve the problems of easy retrogradation of starch, decrease of bread softness, unsatisfactory effect, etc., and achieve the effect of reducing aging probability, ensuring taste and inhibiting retrogradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

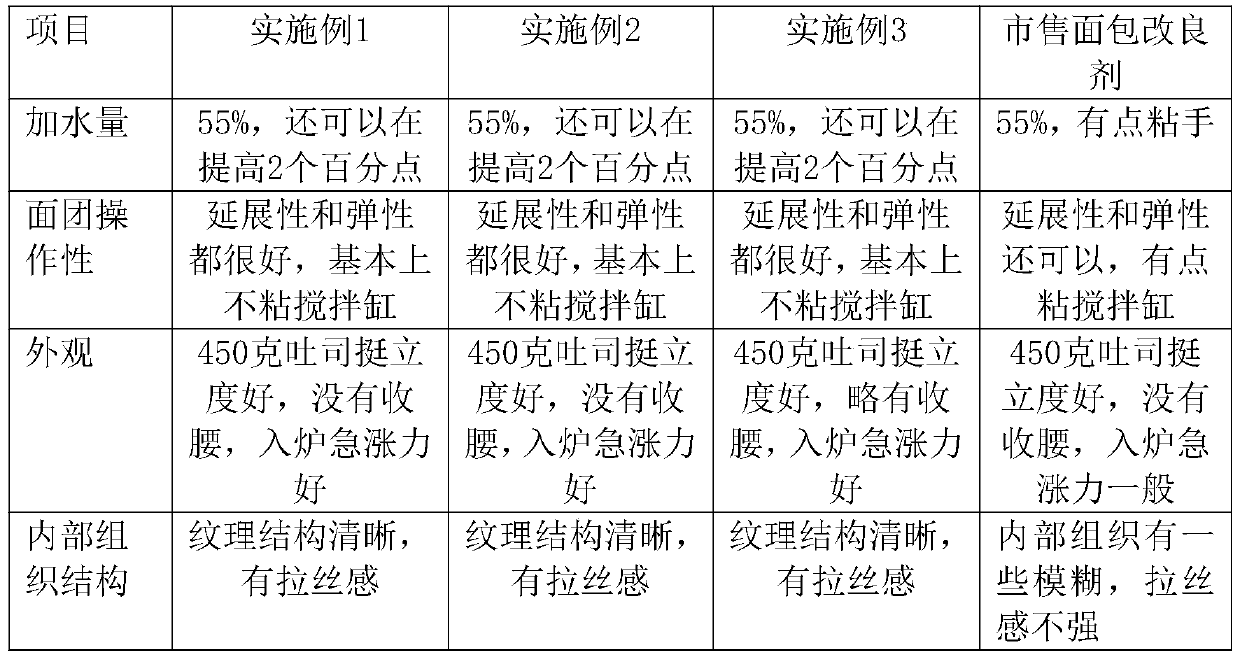

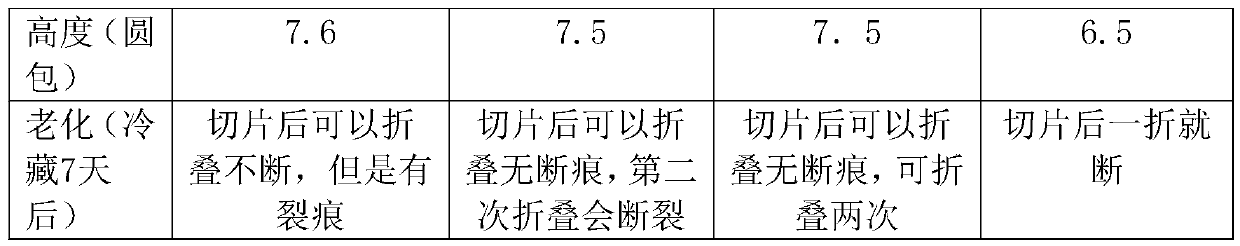

Examples

Embodiment 1

[0021] A production process of soft emulsified paste for bread, which is characterized in that it comprises the following steps:

[0022] Step 1: Prepare the following substances according to the weight ratio formula: mono- and di-glycerin fatty acid ester: 25%, sucrose fatty acid ester: 5%, Span 60: 5%, glycerin: 15%, water: 49%, enzyme preparation: 1%;

[0023] Step 2: Add mono- and di-glycerin fatty acid esters, sucrose fatty acid esters, Span 60, glycerin and water into the stainless steel heating equipment, stir slowly to start heating, and continue stirring after stopping heating;

[0024] Step 3: Keep the stirring process after the heating stopped in Step 2, and stir at constant temperature for 1 hour;

[0025] Step 4: Stop the heat preservation and start to slowly stir and cool down;

[0026] Step 5: Add enzyme preparation, keep the temperature after cooling in step 4 for heat preservation, and stir slowly;

[0027] Step 6: Stop the heat preservation, then gradually stop the sti...

Embodiment 2

[0034] A production process of soft emulsified paste for bread, which is characterized in that it comprises the following steps:

[0035] Step 1: Prepare the following substances according to the weight ratio formula: mono- and diglycerin fatty acid esters: 25%, sucrose fatty acid esters: 5%, Span 60: 5%, glycerin: 15%, water: 48%, enzyme preparation: 2%;

[0036] Step 2: Add mono- and di-glycerin fatty acid esters, sucrose fatty acid esters, Span 60, glycerin and water into the stainless steel heating equipment, stir slowly to start heating, and continue stirring after stopping heating;

[0037] Step 3: Keep the stirring process after the heating stopped in Step 2, and stir at constant temperature for 1 hour;

[0038] Step 4: Stop the heat preservation and start to slowly stir and cool down;

[0039] Step 5: Add enzyme preparation, keep the temperature after cooling in step 4 for heat preservation, and stir slowly;

[0040] Step 6: Stop the heat preservation, then gradually stop the st...

Embodiment 3

[0047] A production process of soft emulsified paste for bread, which is characterized in that it comprises the following steps:

[0048] Step 1: Prepare the following substances according to the weight ratio formula: mono- and di-glycerin fatty acid esters: 25%, sucrose fatty acid esters: 5%, Span 60: 5%, glycerin: 15%, water: 47%, enzyme preparation: 3%;

[0049] Step 2: Add mono- and di-glycerin fatty acid esters, sucrose fatty acid esters, Span 60, glycerin and water into the stainless steel heating equipment, stir slowly to start heating, and continue stirring after stopping heating;

[0050] Step 3: Keep the stirring process after stopping heating in step 2 to keep warm, and stir at constant temperature for 1 hour;

[0051] Step 4: Stop the heat preservation and start to slowly stir and cool down;

[0052] Step 5: Add enzyme preparation, keep the temperature after cooling in step 4 for heat preservation, and stir slowly;

[0053] Step 6: Stop the heat preservation, then gradually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com