Chemically-modified lithium battery diaphragm and preparation method thereof

A lithium battery diaphragm and chemical modification technology, which is applied in the direction of secondary batteries, electrochemical generators, battery components, etc., can solve the problems of diaphragm performance damage, coating layer peeling, and affecting the quality of lithium batteries, etc., to reduce Thermal shrinkage, easy operation, and improved cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention provides a method for preparing a chemically modified lithium battery separator, which includes the following steps:

[0025] Perform activation treatment on the surface of the PE film to form C=O groups on the surface of the PE film; preferably, the activation treatment is to dip the PE film with an activation solution; preferably, the activation solution is an aqueous solution of hydrogen peroxide and nitric acid Mixture; More preferably, the activation solution is hydrogen peroxide and 60-75% by mass nitric acid mixed in a volume ratio of 4-6:1; further preferably, the temperature of the activation treatment is 25-40°C, and the activation treatment The time is 0.5-2h; more preferably, after the surface of the PE film is activated, the activated PE film is washed and dried. Still further preferably, the activated PE film is washed with pure water and then dried.

[0026] A silica film is formed on the surface of the activated PE film; preferably, the...

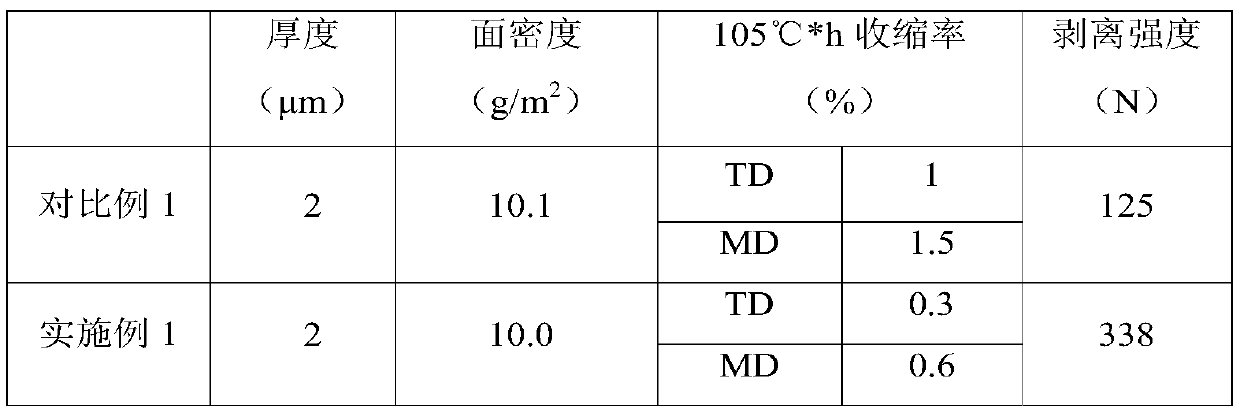

Embodiment 1

[0032] The embodiment of the present invention provides a chemically modified lithium battery separator, which is prepared by using the following steps:

[0033] S11. Perform activation treatment on the surface of the PE film to form C=O groups on the surface of the PE film; specifically, use an activation solution for the immersion treatment on the PE film. The activation solution is hydrogen peroxide and 65% by mass nitric acid. : The volume ratio of 1 is mixed uniformly, the temperature of the activation treatment is 35℃, and the time of the activation treatment is 1h; the activated PE film is washed with pure water and then put into the oven and baked at 60℃ for 2min to dry.

[0034] S12. A silicon dioxide film is formed on the surface of the activated PE film; the activated PE film is immersed in a modification solution, which is obtained by dissolving tetraethoxysilane and ammonium hydroxide in ethanol. The concentration of tetraethoxysilane is 3g / L, the concentration of ammo...

Embodiment 2

[0036] The embodiment of the present invention provides a chemically modified lithium battery separator, which is prepared by using the following steps:

[0037] S21. Perform activation treatment on the surface of the PE film to form C=O groups on the surface of the PE film; specifically, use an activation solution to coat the PE film, the activation solution is hydrogen peroxide and 70% nitric acid by mass The volume ratio of 6:1 is mixed uniformly, the temperature of the activation treatment is 30°C, and the time of the activation treatment is 2h; the activated PE film is washed with pure water and then put into the oven and baked at 60°C for 3min to dry.

[0038] S22. A silicon dioxide film is formed on the surface of the activated PE film; the activated PE film is immersed in a modification solution, which is obtained by dissolving tetraethoxysilane and ammonium hydroxide in propanol, in the modification solution The concentration of tetraethoxysilane is 2g / L, the concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com