A model establishment method for color sensory quality control in a fermented milk production process

A sensory quality and production process technology, applied in the field of color sensory quality control model, can solve the problems of unclear changes in instrument detection indicators and sensory quality, no standards, no degree of certainty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

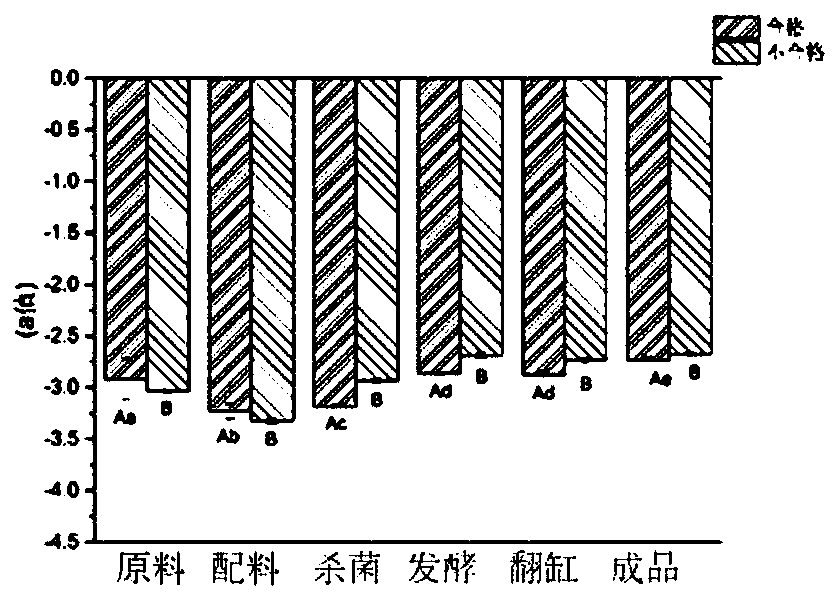

[0036] (1) Collection of fermented milk samples at different key nodes:

[0037] Fermented milk samples at six key points in the fermented milk production process were collected from a dairy factory in Shanghai, divided into different batches, and the fermented milk samples at each key point included 20 qualified samples and 20 unqualified samples.

[0038] (2) Artificial sensory evaluation of fermented milk:

[0039] Refer to the description of sensory properties of yoghurt in GB 19302-2010 "National Food Safety Standard for Fermented Milk" and combine relevant references to determine 2 sensory evaluation factors to describe the sensory properties of fermented milk color, specific evaluation indicators and characteristic descriptions As shown in Table 1.

[0040] Table 1 Sensory evaluation index of fermented milk color

[0041]

[0042]

[0043] Select 10 sensory evaluators with sensitive senses, train them and clarify the evaluation indicators. Use sensory evaluatio...

Embodiment 2

[0067] (1) Collection of fermented milk samples at different key nodes:

[0068] Fermented milk samples at six key points in the fermented milk production process were collected from a dairy factory in Shanghai, divided into different batches, and the fermented milk samples at each key point included 30 qualified samples and 30 unqualified samples.

[0069] (2) Artificial sensory evaluation of fermented milk:

[0070] Refer to the description of sensory properties of yoghurt in GB 19302-2010 "National Food Safety Standard for Fermented Milk" and combine relevant references to determine 2 sensory evaluation factors to describe the sensory properties of fermented milk color, specific evaluation indicators and characteristic descriptions As shown in Table 1.

[0071] Select 10 sensory evaluators with sensitive senses, train them and clarify the evaluation indicators. Use sensory evaluation cups to take 30mL of qualified samples and unqualified samples in seven different ferment...

Embodiment 3

[0095] (1) Collection of fermented milk samples at different key nodes:

[0096] Fermented milk samples at six key points in the fermented milk production process were collected from a dairy factory in Shanghai, divided into different batches, and the fermented milk samples at each key point included 40 qualified samples and 40 unqualified samples.

[0097] (2) Artificial sensory evaluation of fermented milk:

[0098] Refer to the description of sensory properties of yoghurt in GB 19302-2010 "National Food Safety Standard for Fermented Milk" and combine relevant references to determine 2 sensory evaluation factors to describe the sensory properties of fermented milk color, specific evaluation indicators and characteristic descriptions As shown in Table 1.

[0099] Select 10 sensory evaluators with sensitive senses, train them and clarify the evaluation indicators. Use sensory evaluation cups to take 30mL of qualified samples and unqualified samples in seven different ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com