Scintillation screen packaging structure manufacturing method, scintillation screen packaging structure and image detector

A technology of packaging structure and manufacturing method, applied in the field of X-ray radiation imaging, can solve the problems of X-ray overflow, low absorption efficiency, harmful electronic circuits, etc., and achieve the effect of improving X-ray absorption rate and reducing radiation interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] In the present invention, the scintillation screen packaging structure refers to the crystal columnar scintillation screen packaging structure, which is used to convert the incident X-rays into visible light and transmit them to the X-ray image sensor, so that the X-ray image The electronic circuit in the sensor and X-ray image sensor converts the received visible light into an analog signal, converts it into a digital signal through an A / D converter (analog / digital converter), and transmits it to the computer to obtain the initial digital image of the X-ray.

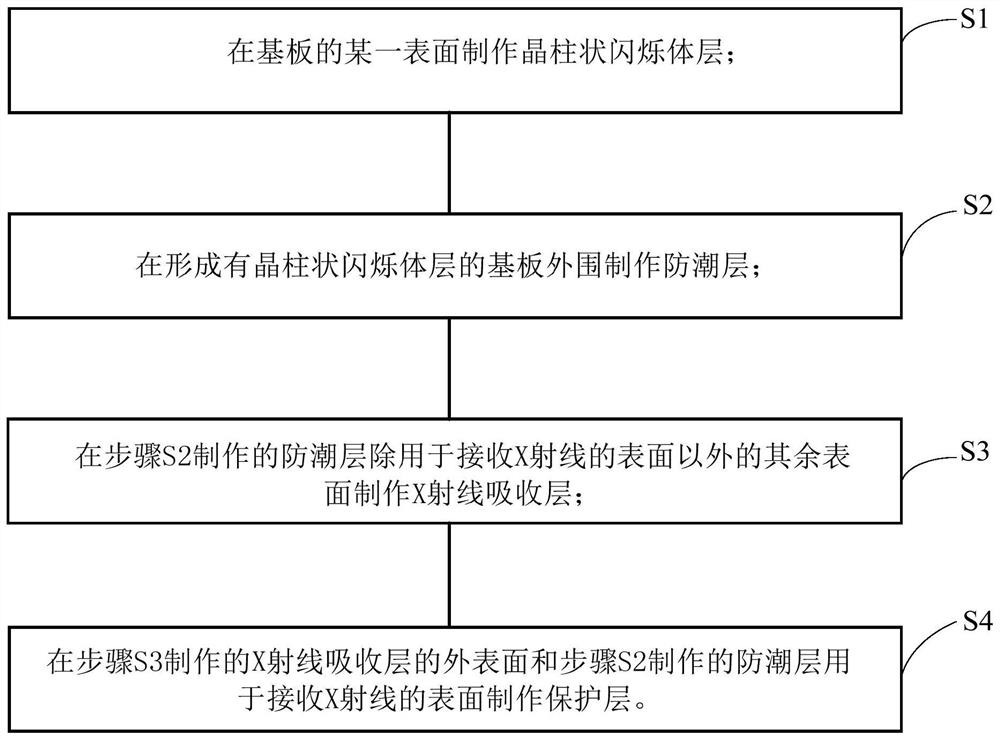

[0042] Such as figure 1 As shown, the manufacturing method of the columnar scintillation screen packaging structure includes the following steps:

[0043] Step S1: making a columnar scintillator layer on a certain surface of the substrate;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com