Novel dynamic and static pressure tilting pad thrust bearing thrust pad structure

A technology of thrust bearings and thrust pads, which is applied to sliding contact bearings, bearings for rotational motion, bearings, etc., and can solve problems such as economic losses, tile burning accidents, and oil film ruptures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

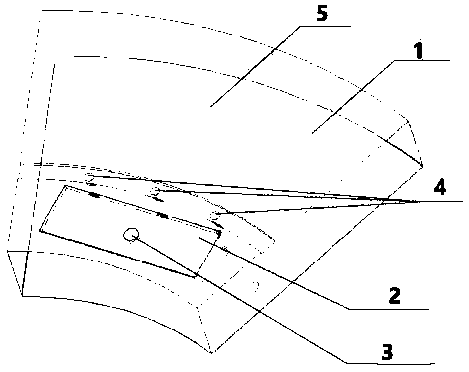

[0010] The specific implementation of the present invention will be described below with reference to the accompanying drawings: a novel dynamic and static pressure tilting pad thrust bearing thrust pad structure, including: main pad body (1), static pressure oil chamber (2), static pressure oil passage (3 ), the oil outlet hole (4) and the temperature sensor (5), the static pressure oil chamber and the dynamic pressure working area are distributed in an area of 1:2, and the depth of the oil chamber is 5mm to ensure the maximum working efficiency of the oil film. There is a 5cm-wide groove between the dynamic pressure part and the static pressure part, and there are 3 oil outlet holes to prevent the oil film from being broken during normal operation. A throttle valve is set in the static pressure oil circuit for Oil pressure is controlled and controlled by a temperature sensor.

[0011] The working process of the thrust pad structure of a new type of dynamic and static press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com