Hydraulic breaking hammer

A hydraulic breaker and liquid technology, applied in fluid pressure converters, fluid pressure actuators, cylinders, etc., can solve the problems of increasing user costs, labor and time, and breakage, so as to improve processing efficiency and reduce use costs , the effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

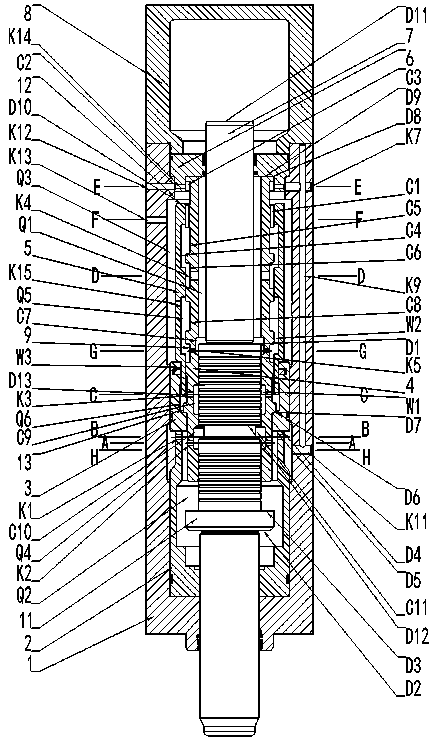

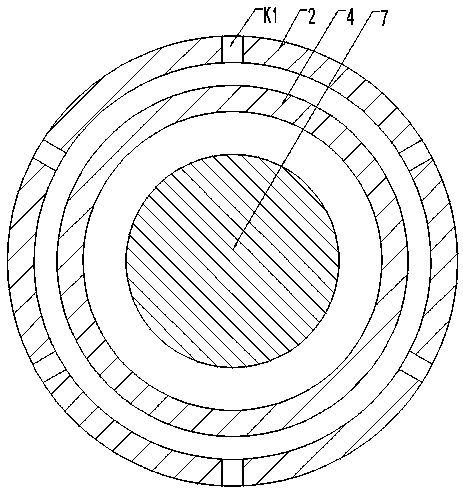

[0055] Examples such as Figure 2-17 As shown, a hydraulic breaker includes a middle cylinder 1 with a cavity inside, a reciprocating piston 7 is arranged inside the middle cylinder 1, and a hydraulic cycle for driving the movement of the piston 7 is arranged between the middle cylinder 1 and the piston 7 System, one end of the middle cylinder 1 is provided with a gas drive mechanism that assists the hydraulic circulation system to drive the piston 7 to move.

[0056] The hydraulic circulation system includes an inner cylinder 4 with a cylindrical structure, and the inner cylinder 4 is coaxially assembled on the piston 7 near one end.

[0057] The outer circumference of the inner cylinder 4 is sequentially provided with a ring-shaped inner cylinder first annular groove C3, an inner cylinder second annular groove C5, an inner cylinder third annular groove C6, and an inner cylinder from one end of the inner cylinder 4 to the other end. The fourth annular groove C8;

[0058] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com