Forced lubrication oil way system for engine

A lubricating oil circuit and engine technology, applied in the direction of engine lubrication, engine components, machines/engines, etc., can solve problems such as poor splash lubrication effect, and achieve the effect of good lubrication effect, improved performance, and prolonged service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

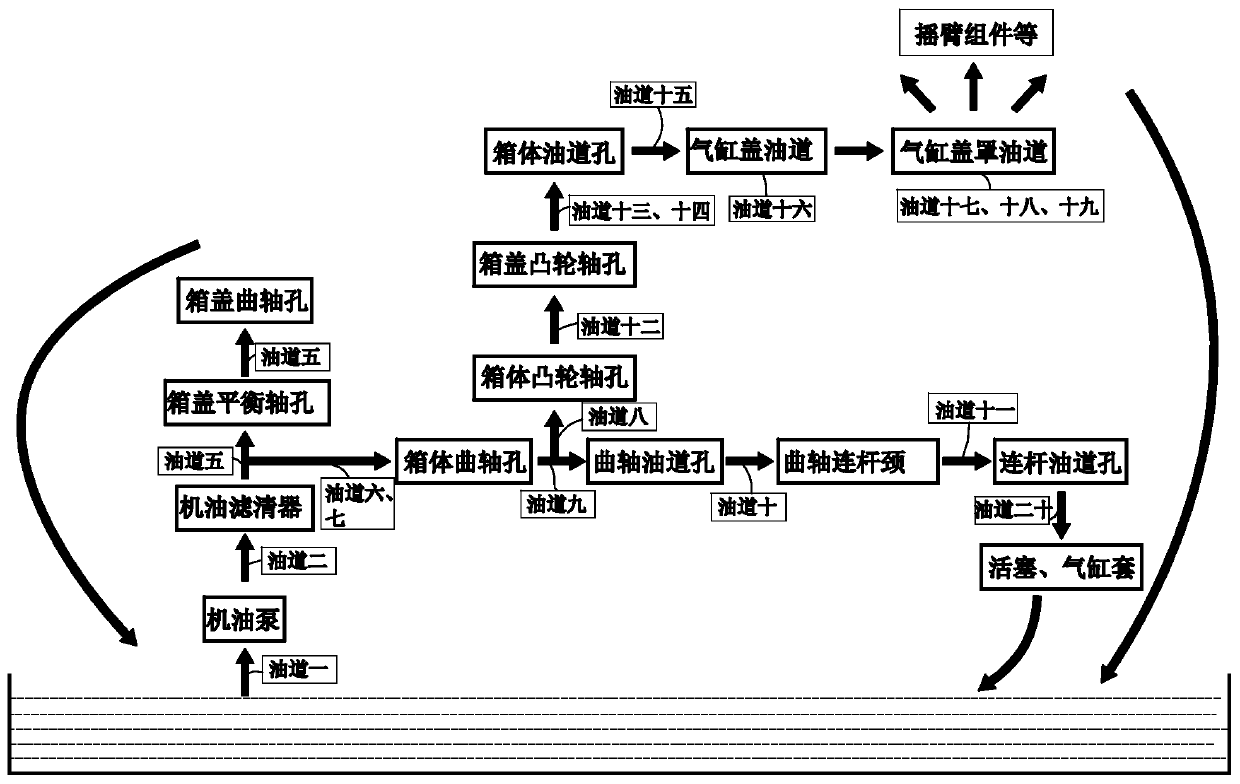

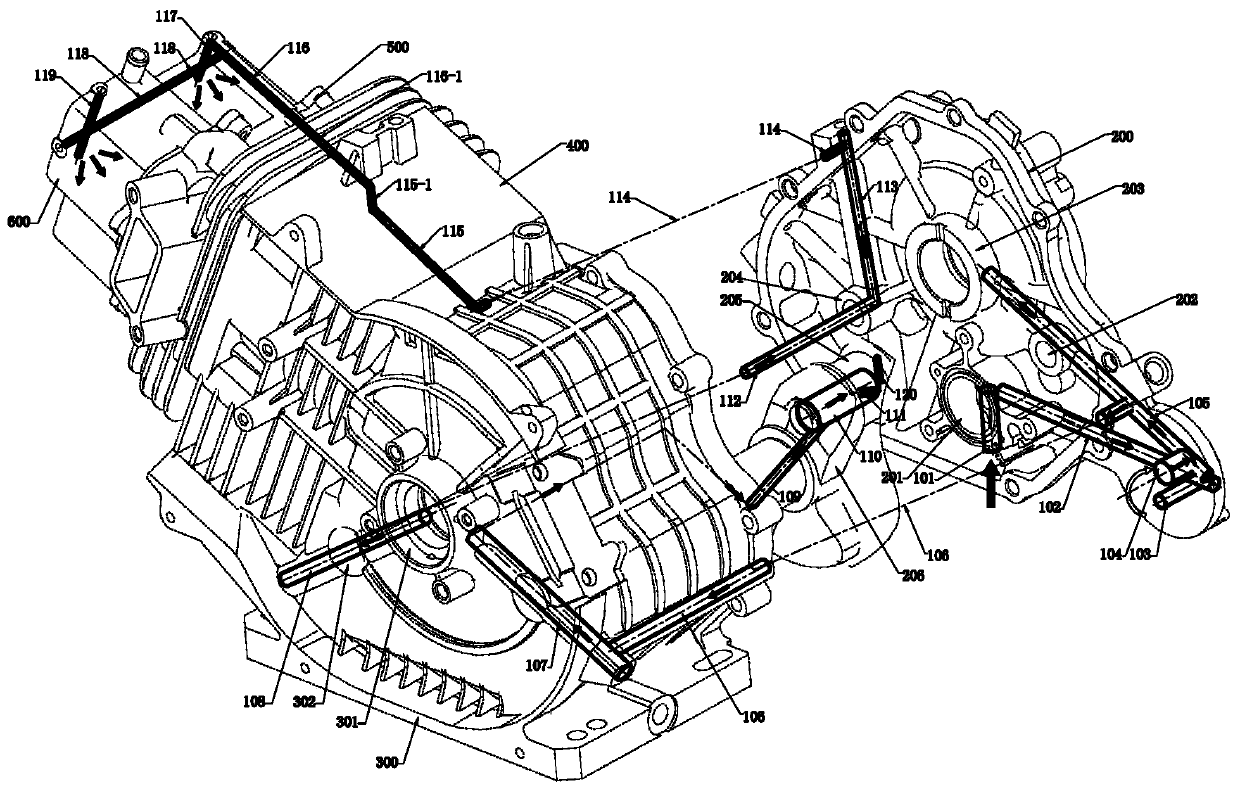

[0031] like figure 1 As shown, this embodiment provides an engine forced lubrication system, including oil passage 101 to oil passage 20 120, oil pump 708, oil cooler 701, filter 704 and filter base 705, oil passage 101 It is vertically arranged at the bottom of the crankcase cover 200 , and its lower end can penetrate into the lubricating oil at the bottom of the crankcase body 300 . The oil pump 708 is installed on the oil pump 708 mounting hole 201 of the crankcase cover 200 , and its suction port communicates with the other end of the oil passage one 101 . The oil passage 2 102 is arranged on the crankcase cover 200 and is arranged horizontally. One end thereof communicates with the discharge port of the oil pump 708, and the other end directly communicates vertically with the oil passage 3 103, forming a linear oil passage as well.

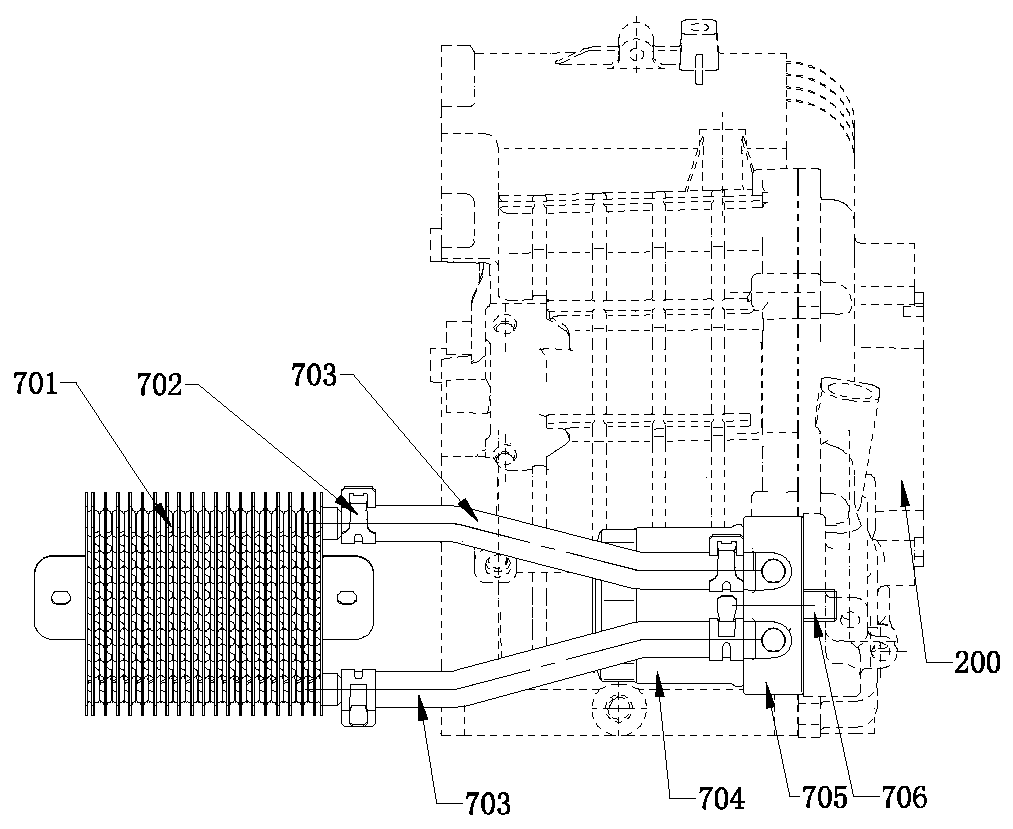

[0032] For the installation and connection of filter base 705 and filter 704, please refer to image 3 , Figure 4 , Figure 5 shown. F...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that a connecting rod oil groove d is provided between the oil passage ten 110 and the oil passage eleven 111, and the connecting rod oil groove d is arranged on the inner wall surface of the 5-axis hole at the big end of the connecting rod. It is an arc-shaped shallow groove that fits the shape of the inner wall of the 5-axis hole at the big end of the connecting rod, which can fully lubricate the connecting rod 4 and the connecting rod neck 205, thereby reducing friction and improving service life.

[0050] Based on the above, the present invention provides a forced lubricating oil circuit structure of the engine, which adopts a large number of linear oil channels and redesigns the forced lubricating oil circuit, which can not only fully lubricate the components with lubrication requirements, but also combine the ad hoc The design of the filter base 705 and the design of the crankshaft assembly 206 greatly redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com