A steel pipe arch bridge suspender preformed hole accurate positioning device

A technology for precise positioning and steel pipe arch bridges, which can be used in bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems of high difficulty in laser alignment or total station measurement and inconsistent guarantee of accuracy, and achieve high positioning accuracy and convenience. The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

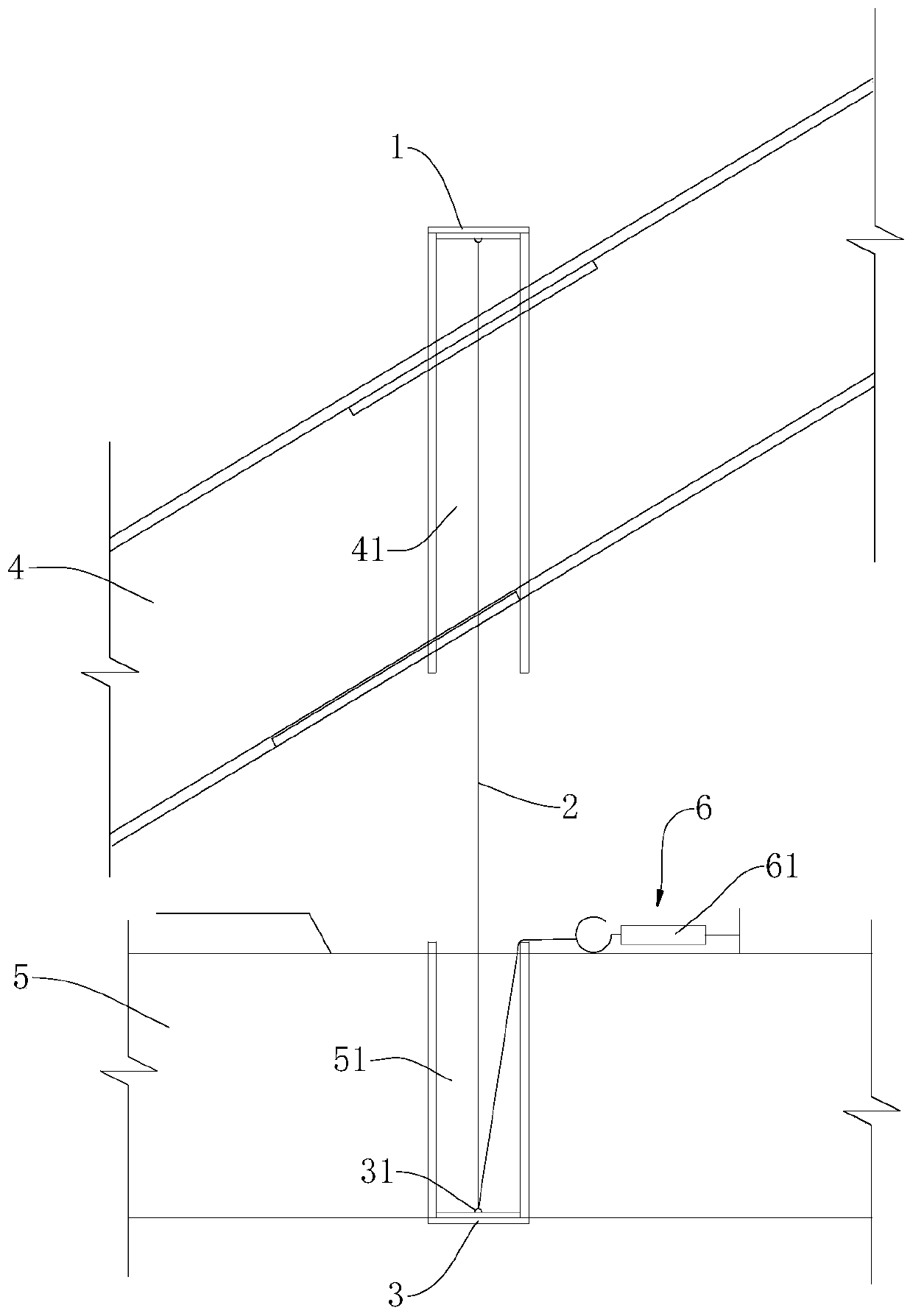

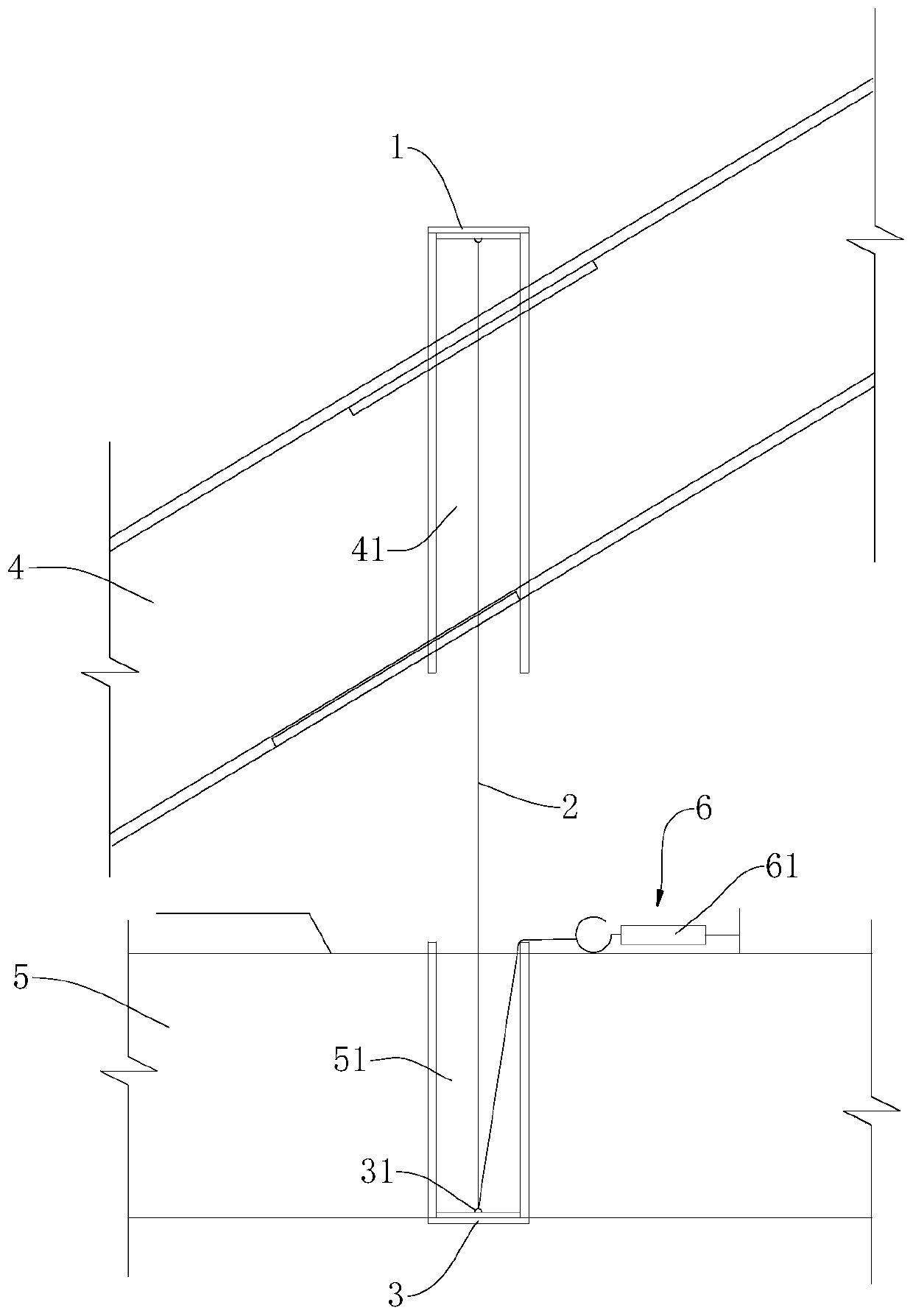

[0020] This embodiment provides a precise positioning device for the reserved hole of the suspender of a steel pipe arch bridge, the structure of which is shown in the figure.

[0021] The precise positioning device for the reserved hole of the steel pipe arch 4 bridge suspender includes the steel wire rope 2 passing through the upper reserved through hole 41 and the lower reserved through hole 51 in sequence, the upper reserved through hole 41 is located on the steel pipe arch 4, and the lower reserved through hole The reserved through hole 51 is located on the beam surface 5, and the two ends of the steel wire rope 2 are respectively set on the central axis of the upper reserved through hole 41 and the lower reserved through hole 51, and the steel wire rope 2 passes through the lower reserved through hole 51 and is connected and tensioned. Part 6, the tension part 6 keeps the wire rope 2 in tension.

[0022] The top of the upper reserved through hole 41 is provided with a st...

Embodiment 2

[0025] A method for locating steel pipe arches and beam surfaces using the precise positioning device of any of the above schemes,

[0026] Pass a steel wire rope 2 through the upper reserved through-hole 41 and the lower reserved through-hole 51 in sequence, respectively fix it on the upper end of the steel pipe arch 4 and the lower end of the beam surface 5, measure the lower opening of the upper reserved through-hole 41 and the lower reserved through-hole respectively 51 catchable deviation, adjust the position of the steel pipe arch 4 accordingly until the requirements are met.

[0027] The present invention avoids the space position deviation between the upper reserved through-hole 41 and the lower reserved through-hole 51 , causing the rigid suspender to be out of position during installation, and ultimately resulting in uneven stress after the suspender is stretched, affecting the durability of the suspender. When the steel pipe arch 4 is installed, it operates synchron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com