Electric motorcycle and power assembly and control method thereof

A technology of electric motorcycles and powertrains, which is applied in the direction of electric vehicles, control drives, control devices, etc., and can solve the problems affecting the power battery pack endurance and rechargeable cycles, service efficiency and service life decline, and power battery pack capacity. Problems such as decline, to achieve the effect of ensuring battery life and service life, prolonging service life and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

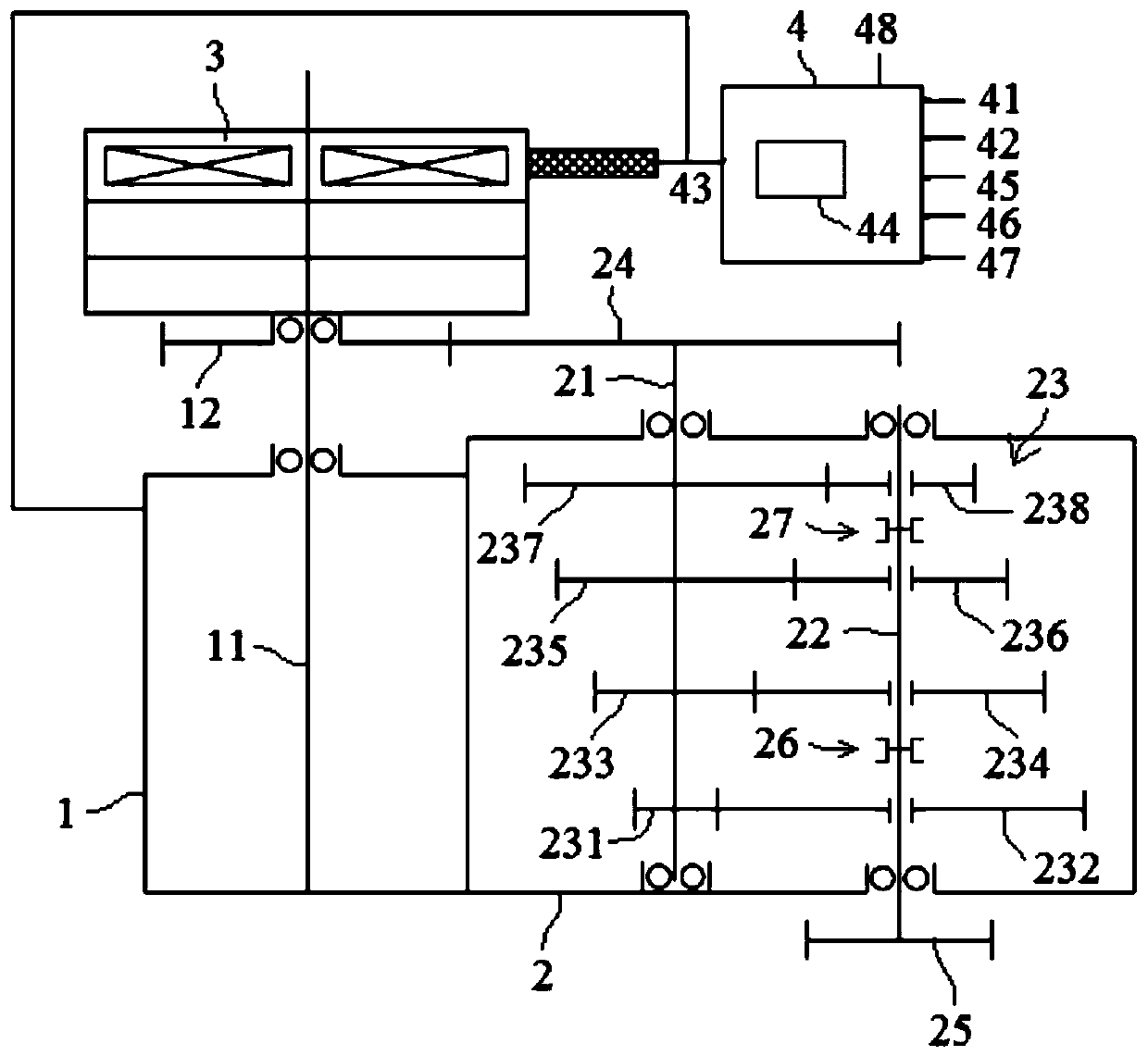

[0039] Please refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the power assembly of the electric motorcycle provided by the present invention.

[0040] Such as figure 1 As shown, the present invention provides a power assembly of an electric motorcycle, including a motor 1, a gearbox 2 and a clutch 3, the gearbox 2 has several gears, and the clutch 3 can be connected to the rotating shaft 11 of the motor 1 and the clutch 2 of the gearbox 2. Input shaft 21 .

[0041] Different from the fixed speed ratio scheme in the prior art, the power assembly provided by the present invention also includes a gearbox 2, the gearbox 2 has several gears, and can provide different speed ratios. By switching gears, the motor 1 can The high-efficiency working state is maintained in a relatively large speed range, which can largely prevent the motor 1 from working at the limit speed state for a long time, and can reduce the time for the high-current...

Embodiment 2

[0067] The present invention also provides an electric motorcycle, including a power assembly, and the power assembly is the power assembly of the electric motorcycle involved in each implementation manner in the first embodiment.

[0068] Since the powertrain of the electric motorcycle in the first embodiment already has the above technical effects, then the electric motorcycle with the powertrain should also have similar technical effects, so it will not be repeated here.

Embodiment 3

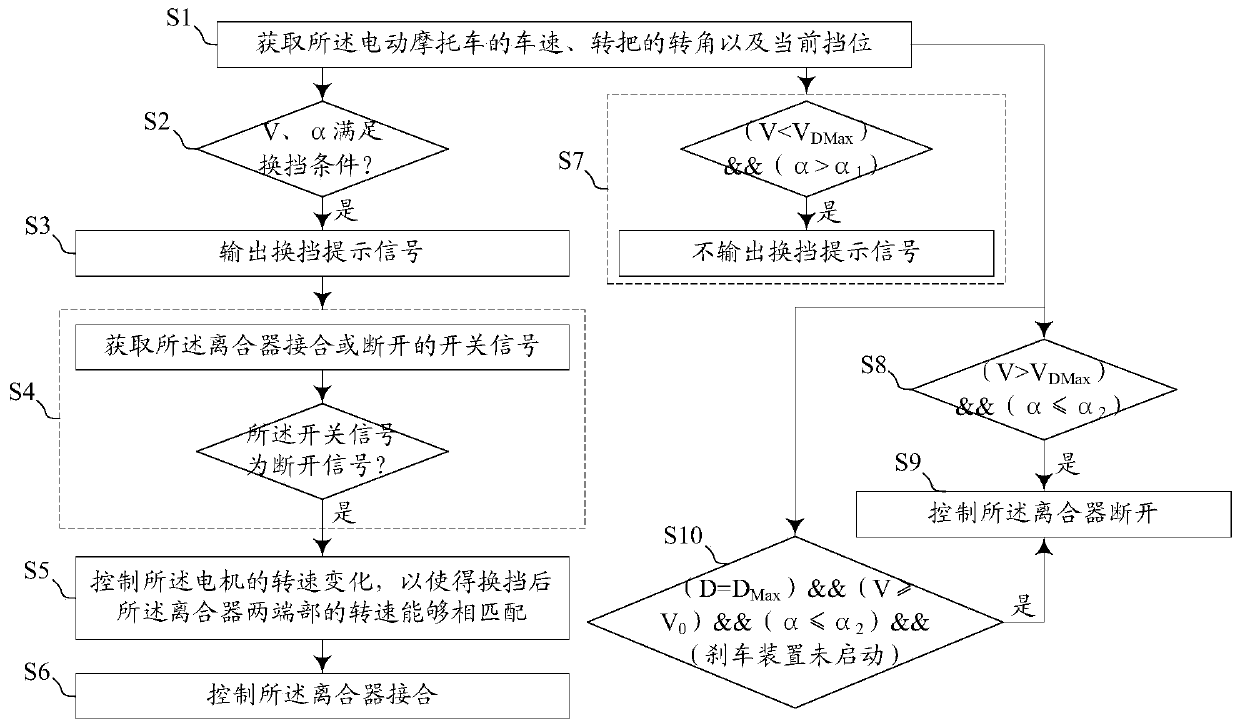

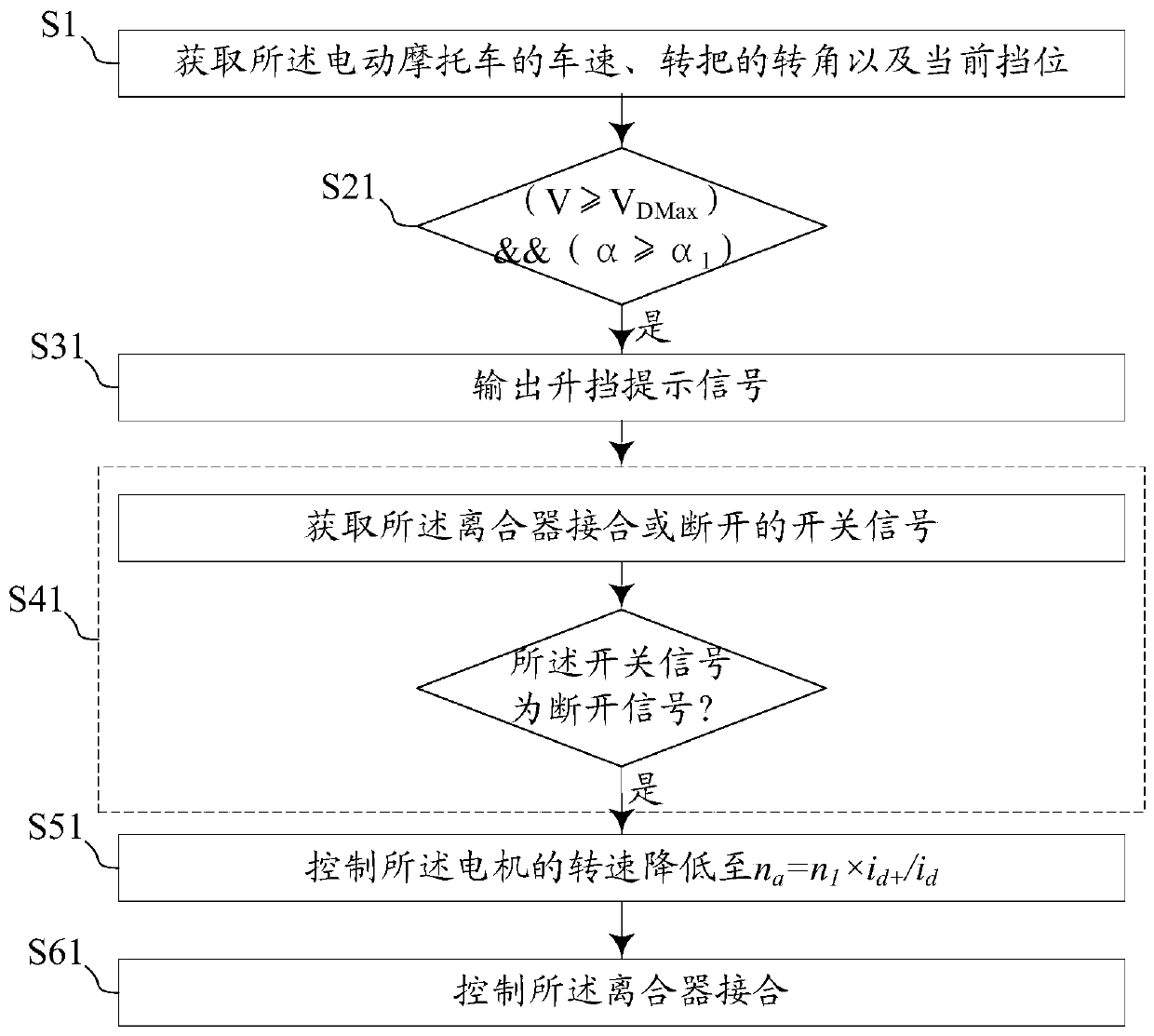

[0070] Please refer to Figure 2-4 , figure 2 It is a flow chart of the control method of the electric motorcycle provided by the present invention, image 3 It is a flow chart of the control method of the electric motorcycle provided by the present invention in the process of upshifting, Figure 4 It is a flow chart of the control method of the electric motorcycle provided by the present invention during the downshifting process.

[0071] Such as figure 2 As shown, the present invention also provides a control method for an electric motorcycle, which is suitable for the electric motorcycle in Embodiment 2. The control method specifically includes the following steps: Step S1, obtaining the vehicle speed V and the turning angle of the electric motorcycle α and the current gear position D; step S2, determine whether the vehicle speed V and the rotation angle α meet the shifting conditions, if so, execute step S3; step S3, output the shift prompt signal; step S4, obtain the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com