A kind of manufacturing method of automobile interior environment-friendly waterproof fabric

A technology of waterproof fabric and production method, which is applied in the field of fabric, can solve the problems of single use, no flame retardancy, waterproof, etc., and achieve the effect of improving affinity, cheap price, and improving antibacterial and anti-ultraviolet functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

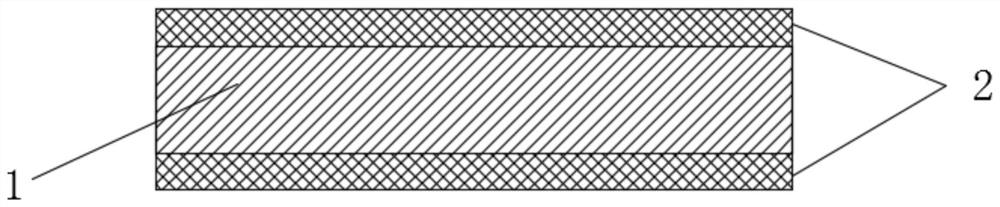

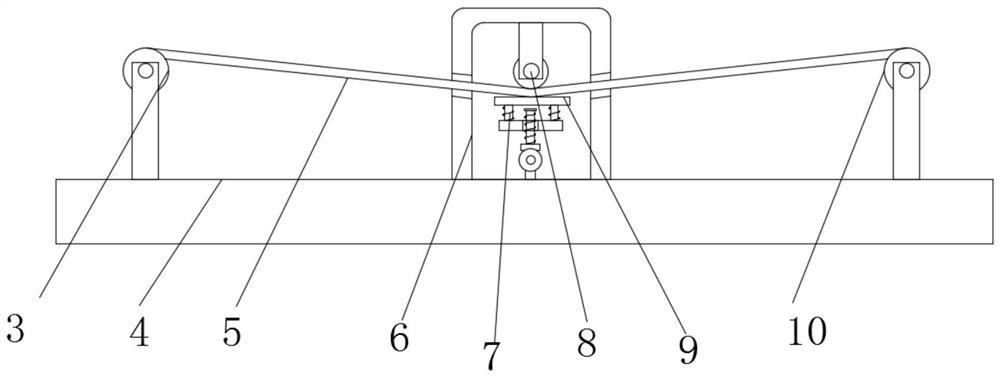

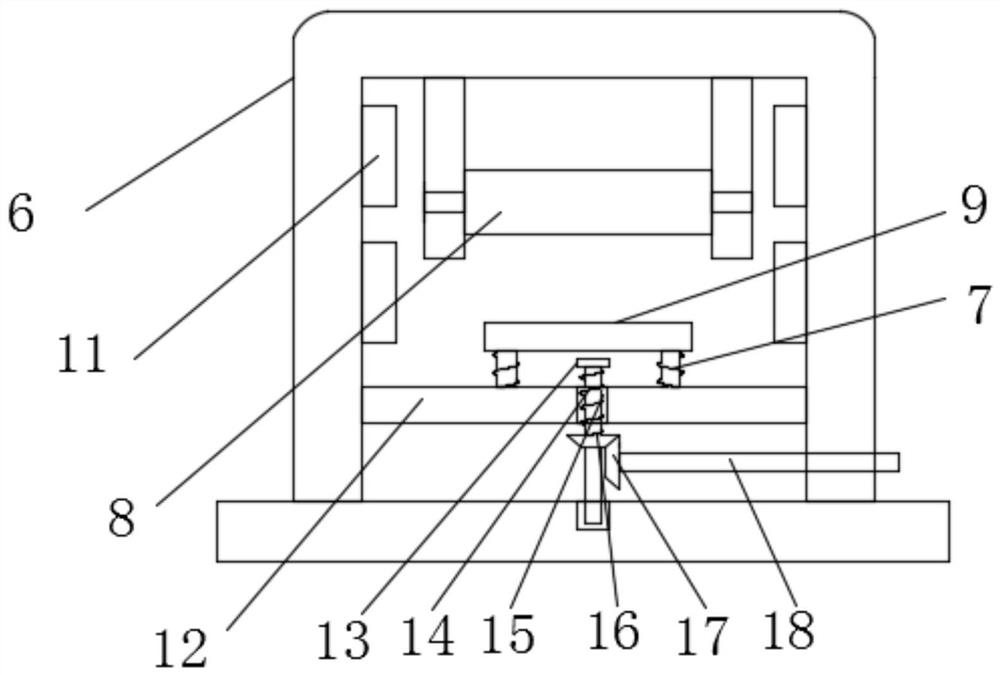

[0037] see Figure 1-3 Shown, a kind of manufacture method of automobile interior environment-friendly waterproof fabric, this environment-friendly waterproof fabric comprises base layer 1, and the upper and lower sides of base layer 1 are all provided with waterproof layer 2; Base layer 1 is prepared by following raw materials by weight: 60 parts of cotton fiber , 5 parts of shell fiber, 60 parts of polypropylene fiber, 1 part of bamboo fiber, 60 parts of PET fiber; the waterproof layer 2 is prepared by the following raw materials in parts by weight: 60 parts of PE fiber, 45 parts of PA fiber, 0.5 part of flame retardant, 0.5 parts of antibacterial agent, 0.3 parts of modified aging agent, 0.3 parts of coupling agent;

[0038] Wherein, the environment-friendly waterproof fabric is prepared through the following steps:

[0039] A. Preparation of base layer 1: First, cotton fiber, chitin fiber, polypropylene fiber, bamboo fiber, and PET fiber are added to the extruder and mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com