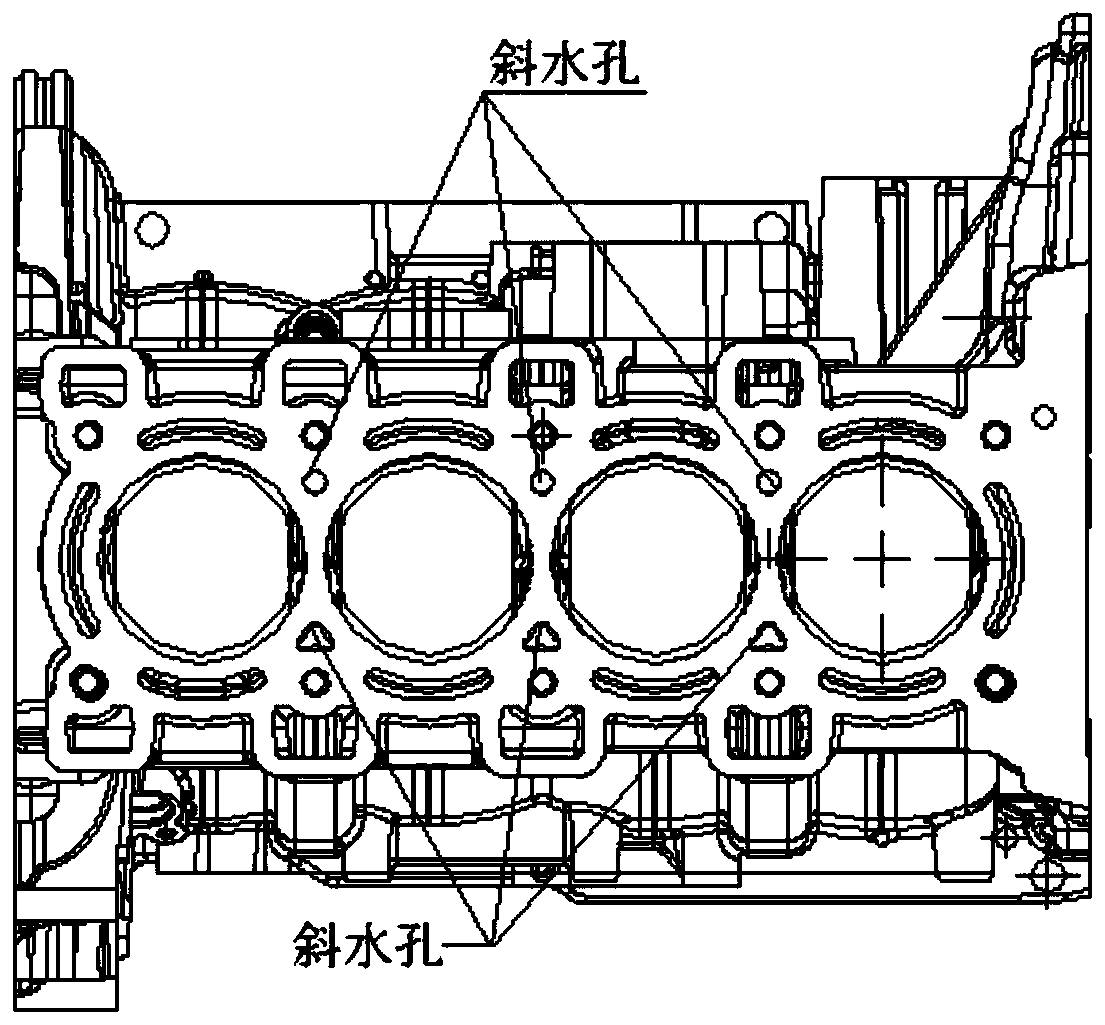

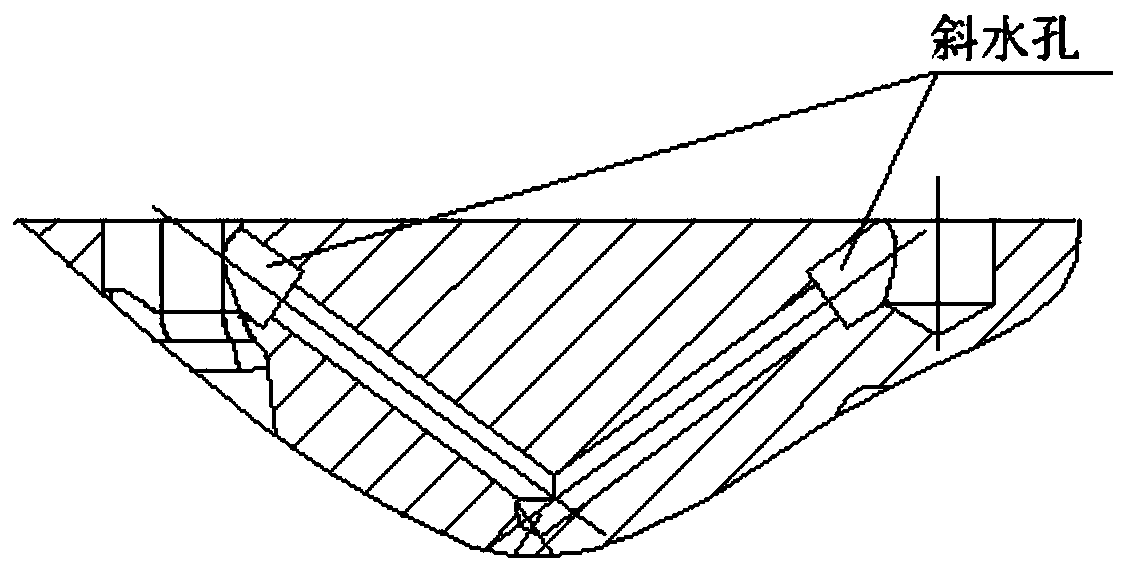

Clamp for machining engine cylinder oblique water hole and machining method

An engine block and processing method technology, which is applied to metal processing mechanical parts, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to guarantee the angle, position and symmetry of the inclined hole, so as to prevent processing errors and improve product qualification. The effect of improving efficiency and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

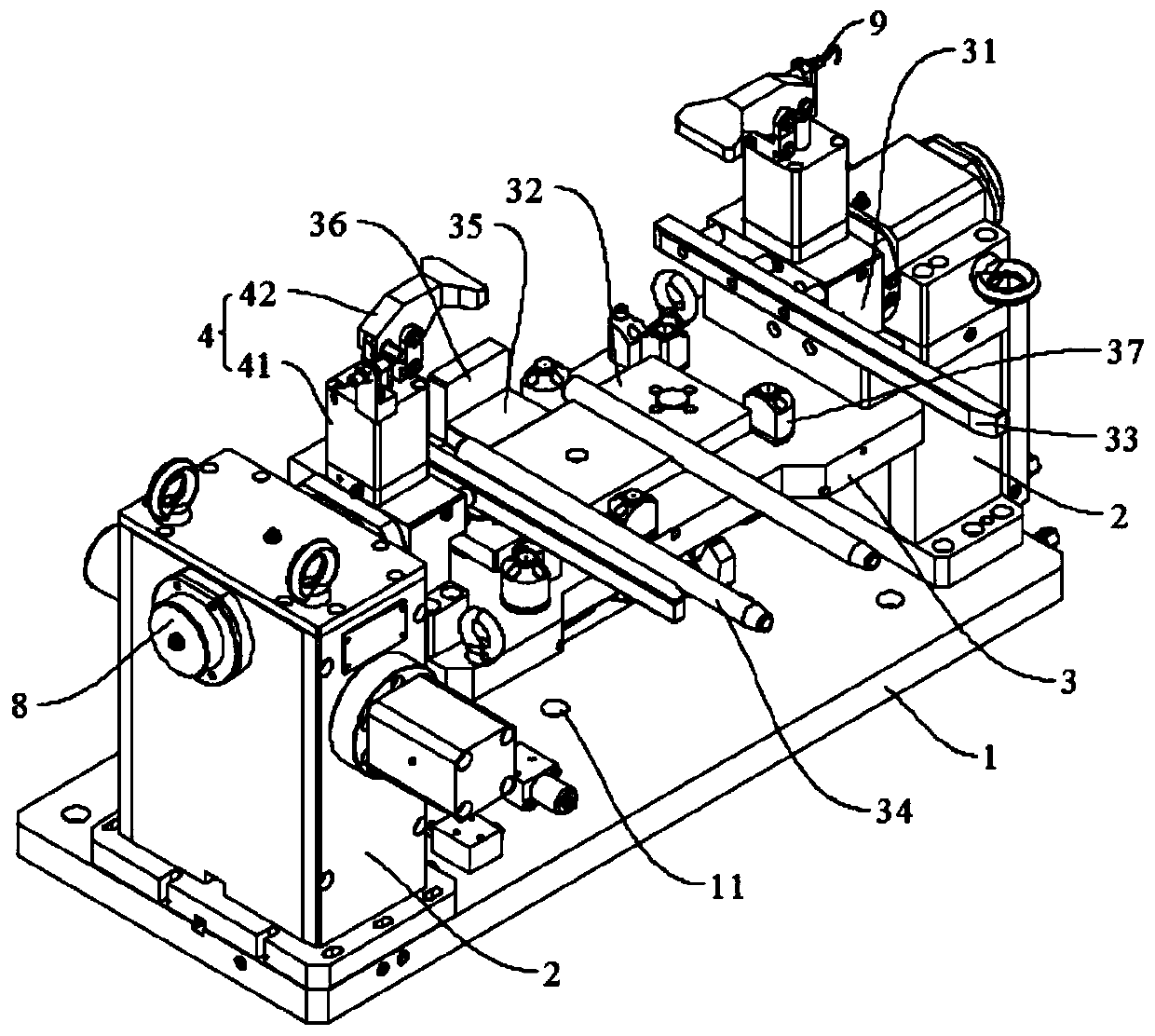

[0028] As shown in the figure: the fixture for processing the inclined water hole of the engine cylinder, the fixture includes a bottom plate 1, a support column 2 and a clamping mechanism, the support column 2 is set on the bottom plate 1, and the clamping mechanism is connected to the support column 2, and can hold the engine block, and can also rotate the engine block to a predetermined angle.

[0029] Further, there are two supporting columns 2, and they are relatively fixed on both ends of the bottom plate 1, and a rotating mechanism 8 is provided on one or both sides of the supporting columns, and the rotating mechanism 8 is connected with the clamping mechanism , and can drive the clamping mechanism to rotate to a predetermined angle.

[0030] The clamping mechanism includes a supporting plate 3, a pressing assembly 4, and connecting risers 31 vertically installed at both ends of the supporting plate. The clamping mechanism as a whole rotates around the rotating shaft ...

Embodiment 2

[0039] On the basis of Embodiment 1, it also includes an angle control mechanism 5, which includes an air-tight detection plate 51 installed on the bottom plate 1, and a positioning pad 52 installed on the bottom of the pallet 3; the positioning The spacer 52 and the airtight detection plate 51 correspond to each other, and when the supporting plate 3 is overturned in place, they are attached to each other, so as to control the supporting plate 3 to be quickly overturned in place (the flipping angle of the fixture is the angle between the inclined water hole and the upper plane of the product) consistent). The air-tight detection plate 51 is designed with an air-tight hole 51a, and when the supporting plate 3 completes the overturning action, and the gap between the positioning pad 52 and the air-tight detection plate 51 exceeds the set gap value, an alarm will be given automatically.

[0040] The clamp also includes a flip detection mechanism located on the base plate 1, the ...

Embodiment 3

[0042] In this embodiment, the fixture is also provided with an auxiliary holding mechanism for the turning angle. When the supporting plate 3 is turned over to a position, the auxiliary holding mechanism can control the supporting plate 3 to be stably held at the corresponding turning angle position. Further, the auxiliary holding mechanism is set as a pressing cylinder 12, which is installed on the bottom plate 1. When the supporting plate 3 is overturned in place, the pressing oil cylinder 12 supports the supporting plate 3 by extending the piston rod to continuously maintain the overturning. angle.

[0043] The base plate 1 is provided with a slant plate 13, the slant plate 13 is installed on the base plate 1 with a certain inclination, and the inclination of the slant plate 13 relative to the base plate 1 is equal to the inclination of the inclined water hole. The aforementioned angle in place detection probe 7, pressing oil cylinder 12 and airtight detection plate 51 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com