High-pressure sprayer for pipeline cleaning

A technology for cleaning high-pressure nozzles and pipes, used in cleaning methods and utensils, spraying devices, cleaning hollow objects, etc., can solve the problems of insufficient stability and low effect, and achieve the effect of improving efficiency and increasing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In this technical solution:

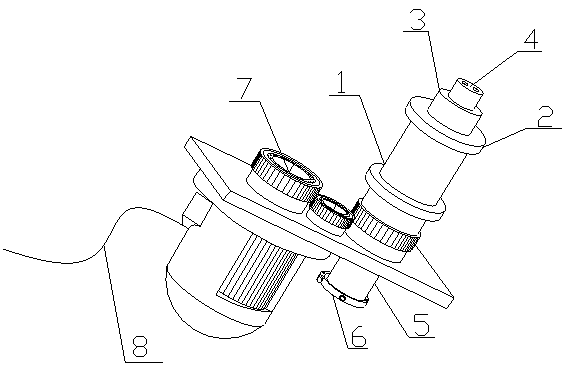

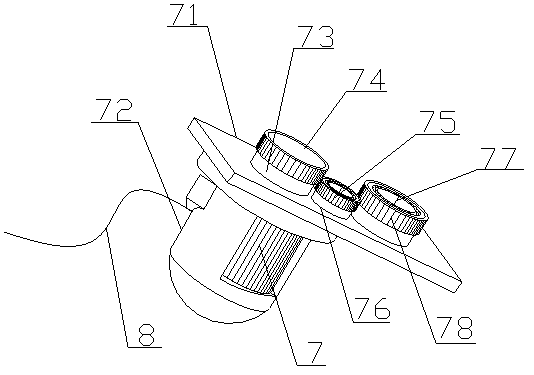

[0026] Pipe clamp device 6, rotating device 7, first half ring 61, second half ring 62, connecting hole 63, fixing piece 64, rotating handle 65, connecting plate 71, driving motor 72, rotating shaft 73, first gear 74 , the second gear 75, the first bearing 76, the third gear 77 and the second bearing 78 are substantially innovative components contained in the present invention.

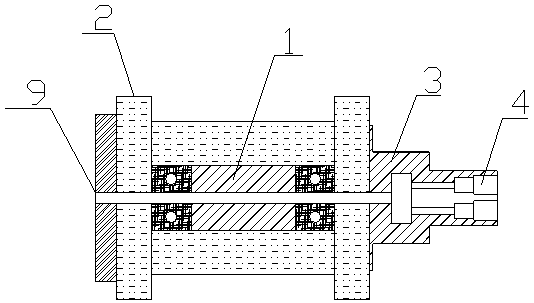

[0027] The nozzle main body 1, the outer shaft fixing ring 2, the nozzle fixing seat 3, the nozzle 4, the water inlet pipe 5, the power cord 8 and the water inlet pipeline 9 are the indispensable connecting components for realizing the technical solution of the present invention.

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com