Herringbone foundation pit supporting structure

A foundation pit support, herringbone technology, applied in the direction of foundation structure engineering, excavation, construction, etc., can solve the problems of low strength, bearing capacity depends on compressive strength, poor overall stability, etc., to achieve the reduction of pile diameter and longitudinal distribution The effect of improving the ratio of tendons, improving the distribution of internal forces, and improving stiffness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

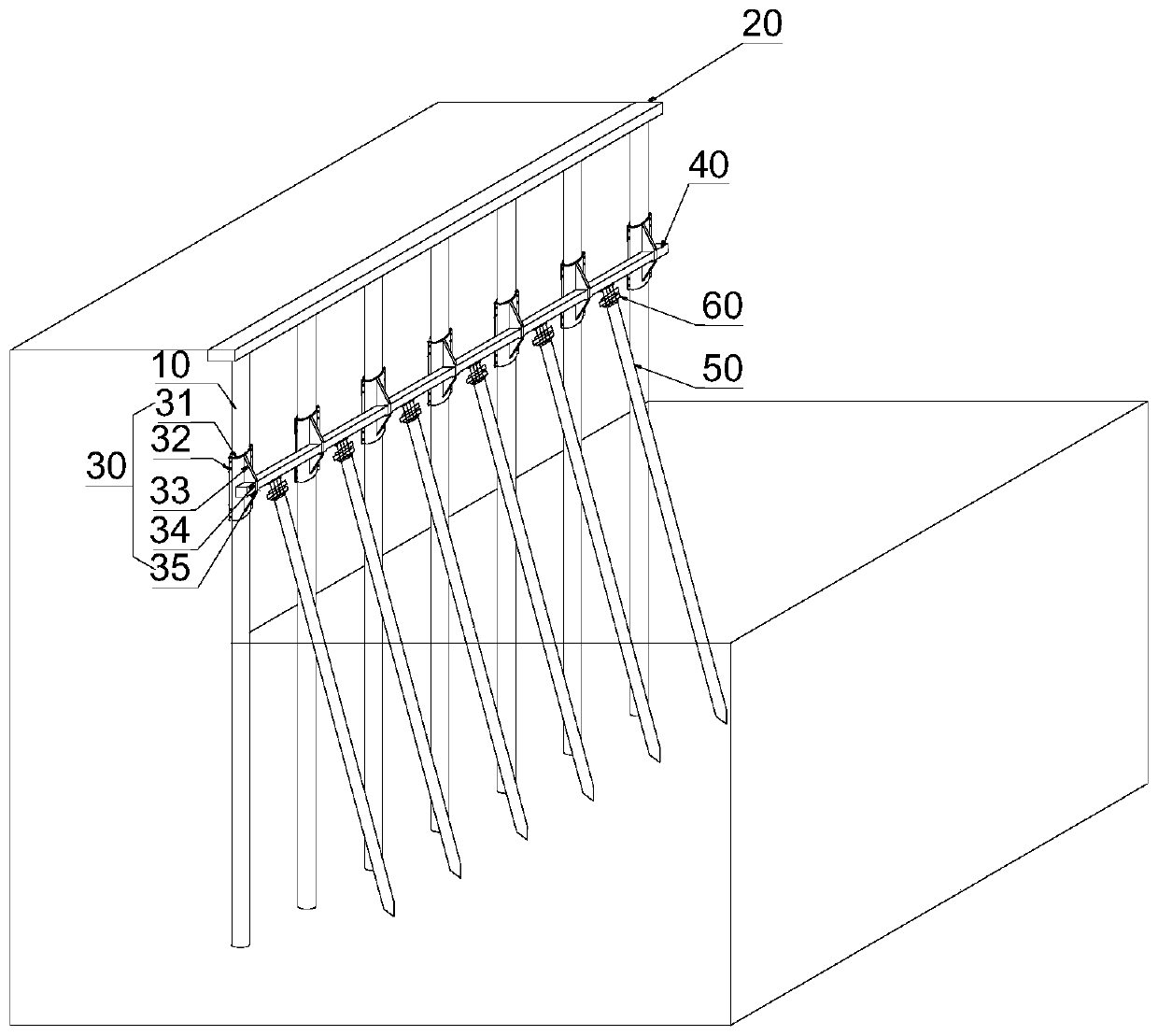

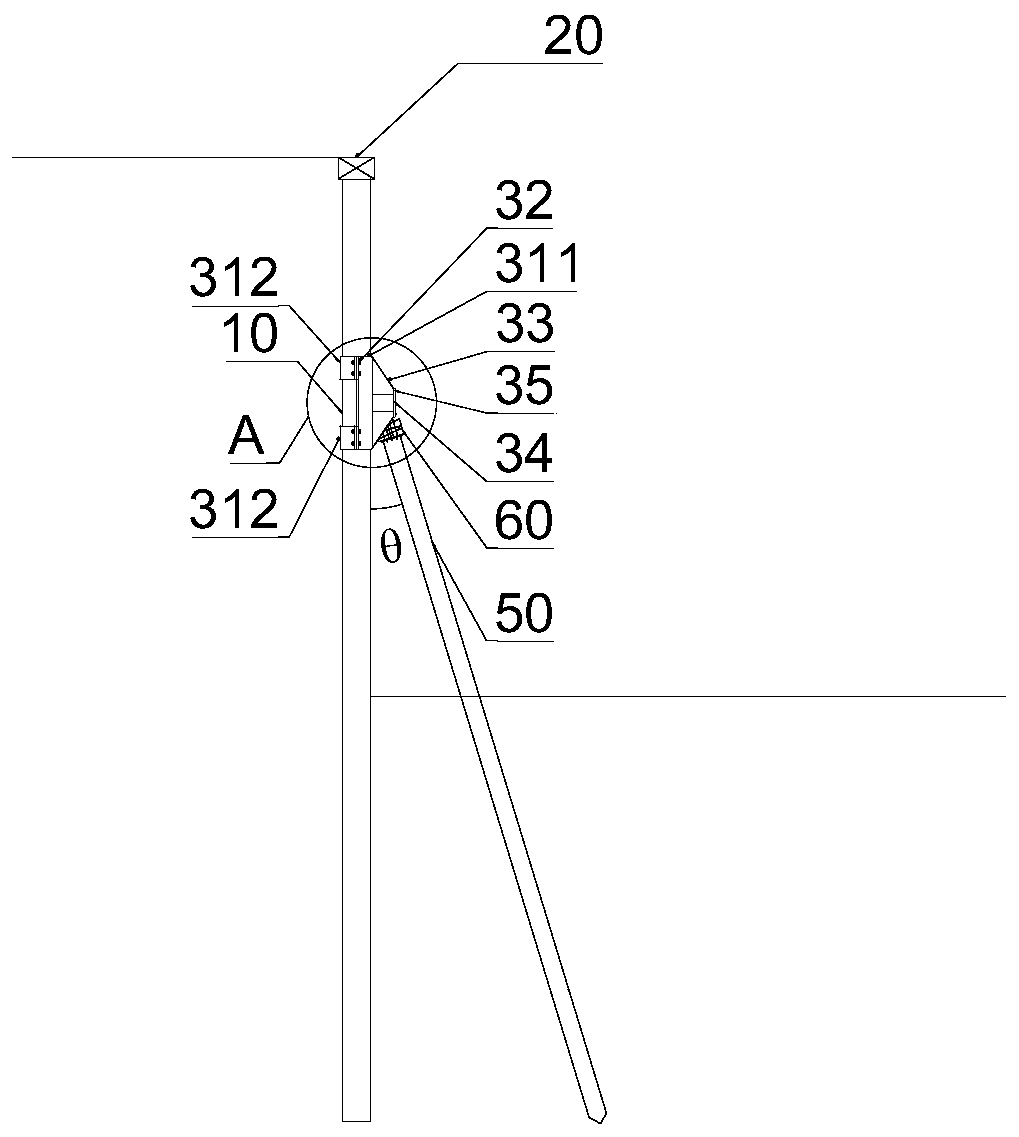

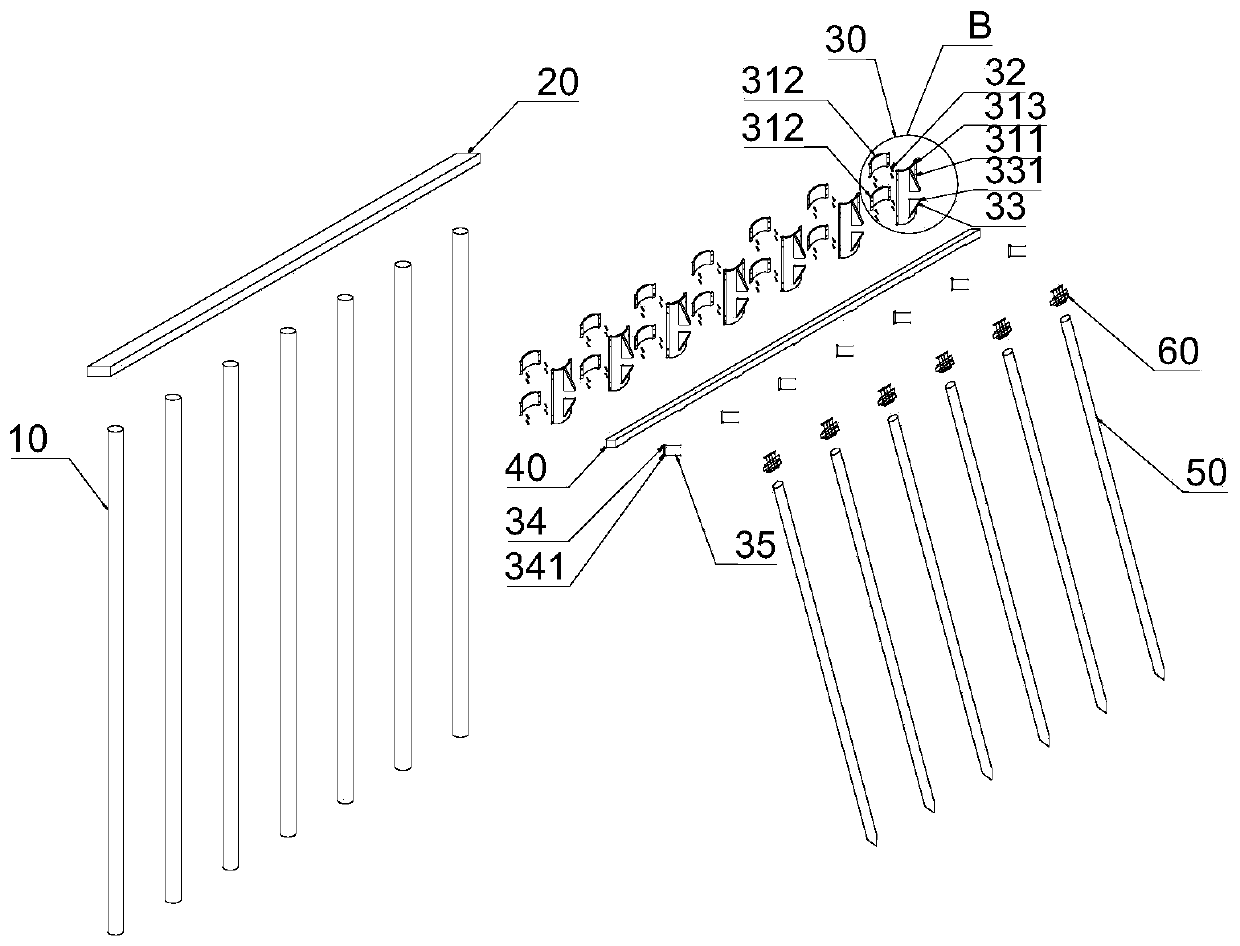

[0039] according to Figure 1a , Figure 1b , figure 2 , Figure 3a , Figure 3b , Figure 4 , Figure 5 , Image 6 It can be seen that a herringbone foundation pit support structure mainly includes upright piles 10, crown beams 20, waist beam brackets 30, locking tiles 31, front support tiles 311, rear fixed tiles 312, and bolt mounting holes 313 , locking bolt 32, waist beam card platform 33, bolt mounting hole 331, fastening pressure plate 34, bolt mounting hole 341, pressure plate fastening bolt 35, waist beam 40, inclined pile 50, active joint 60. It is characterized in that: the upright piles 10 are vertically distributed on the edge of the foundation pit to be excavated, and the tops of the piles are connected by pouring crown beams to jointly bear the soil pressure outside the foundation pit, and a waist beam bracket 30 is installed at the waist of the upright piles 10 . The waist beam bracket 30 is a prefabricated component, and the waist beam bracket 30 includ...

Embodiment 2

[0051] according to Figure 7a with Figure 7b It can be seen that a herringbone foundation pit support structure mainly includes upright piles 10, crown beams 20, waist beam brackets 30, locking tiles 31, front support tiles 311, rear fixed tiles 312, and bolt mounting holes 313 , locking bolt 32, waist beam card platform 33, bolt mounting hole 331, fastening pressure plate 34, bolt mounting hole 341, pressure plate fastening bolt 35, first waist beam 41, second waist beam 42, first inclined pile 51 , the second inclined pile 52, the active joint 60. It is characterized in that: the upright piles 10 are vertically distributed on the edge of the foundation pit to be excavated, the tops of the piles are connected by pouring crown beams, and jointly bear the soil pressure outside the foundation pit, the first waist beam position and the second waist beam position are respectively installed with waist beam supports Seat 30.

[0052] The waist beam bracket 30 is a prefabricated...

Embodiment 3

[0063] according to Figure 8a with Figure 8b It can be seen that a herringbone foundation pit support structure mainly includes upright piles 10, crown beams 20, waist beam brackets 30, locking tiles 31, front support tiles 311, rear fixed tiles 312, and bolt mounting holes 313 , locking bolt 32, waist beam card platform 33, bolt mounting hole 331, fastening pressure plate 34, bolt mounting hole 341, pressure plate fastening bolt 35, waist beam 40, inclined pile 50, active joint 60. It is characterized in that: the upright piles 10 are vertically distributed on the edge of the foundation pit to be excavated, the tops of the piles are connected by pouring crown beams, and jointly bear the soil pressure outside the foundation pit, the first waist beam position and the second waist beam position are respectively installed with waist beam supports Seat 30.

[0064] The waist beam bracket 30 is a prefabricated component, and the waist beam bracket 30 includes a locking tile 31,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com