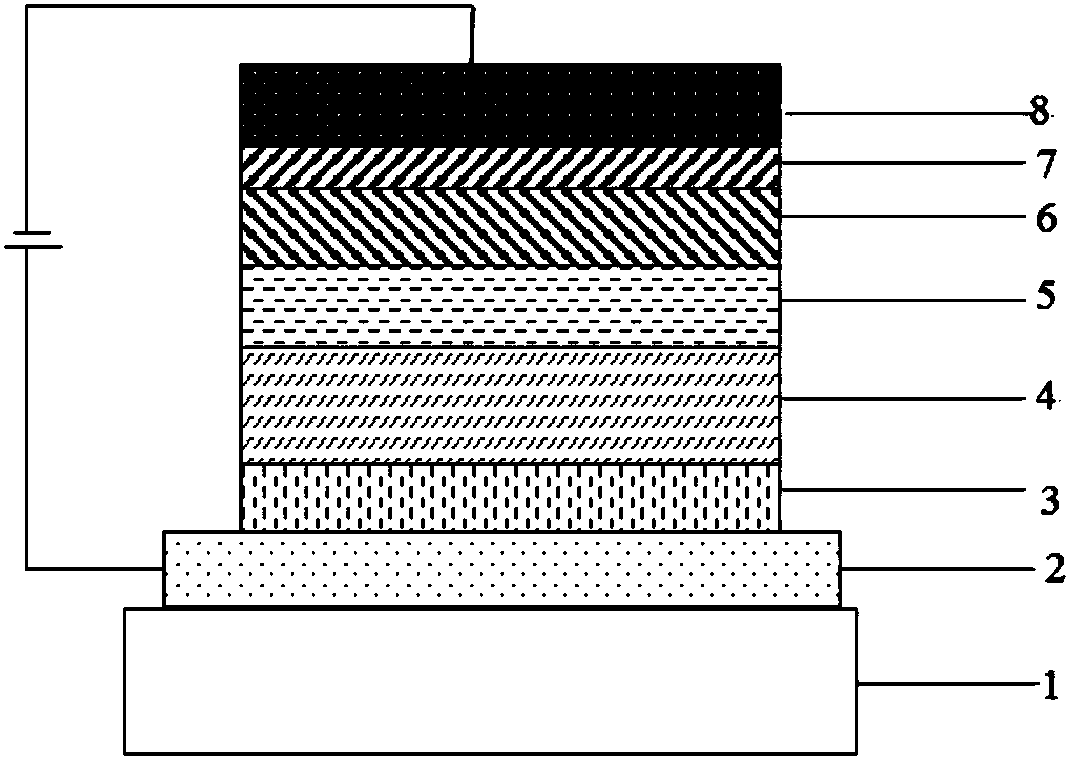

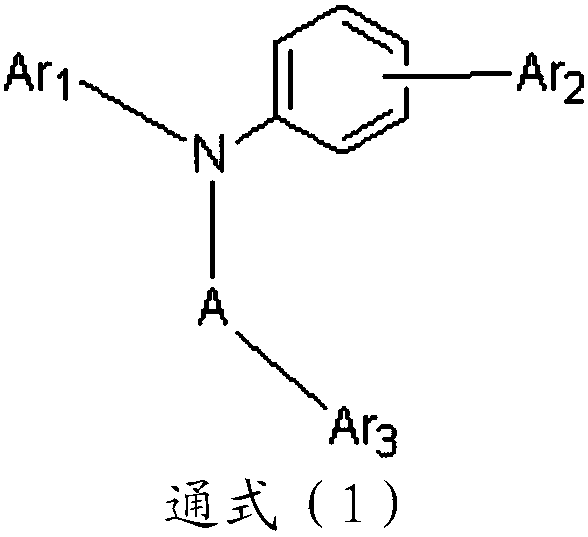

Triarylamine-based compound and preparation method thereof, and applications of triarylamine-based compound in organic electroluminescent devices

An electroluminescent device, triarylamine technology, applied in the fields of electro-solid devices, chemical instruments and methods, electrical components, etc., can solve problems such as different problems, reduce cross-color phenomenon, good film-forming properties, and good industrialization prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 3

[0046] The preparation of embodiment 1 triaromatic amine compound

Embodiment 1-1

[0047] Embodiment 1-1: Preparation of compound 1

[0048] The chemical reaction equation that takes place in the preparation process of compound 1 is as follows:

[0049]

[0050] Concrete preparation steps are as follows:

[0051] (1) Preparation of Intermediate 1

[0052] 10mmol 4-(1-naphthyl)aniline (2.2g), 10mmol 1-bromopyrene (2.8g), 20mmol sodium tert-butoxide (2.0g), 0.1mmol Pd 2 (dba) 3 (0.1g) and 50ml of toluene were added to the reaction flask in turn, refluxed for 10h under nitrogen protection, cooled to room temperature, added 100ml of water, separated, the aqueous layer was extracted with ethyl acetate and combined with the organic layer, and saturated saline and water were sequentially After washing, the organic layer was dried with magnesium sulfate, filtered, the filtrate was rotary evaporated, and passed through a silica gel column to obtain Intermediate 1 with a HPLC purity of 99.5%;

[0053] (2) Preparation of compound 1

[0054] 10mmol of the above ...

Embodiment 1-2

[0055] Embodiment 1-2: Preparation of Compound 2

[0056] The chemical reaction equation that takes place in the preparation process of compound 2 is as follows:

[0057]

[0058] Concrete preparation steps are as follows:

[0059] (1) Preparation of Intermediate 2

[0060] 10mmol 4-(2-naphthyl)aniline (2.2g), 10mmol 1-bromopyrene (2.8g), 20mmol sodium tert-butoxide (2.0g), 0.1mmol Pd 2 (dba) 3 (0.1g) and 50ml of toluene were added to the reaction flask in turn, refluxed for 10h under nitrogen protection, cooled to room temperature, added 100ml of water, separated, the aqueous layer was extracted with ethyl acetate and combined with the organic layer, and saturated saline and water were sequentially After washing, the organic layer was dried with magnesium sulfate, filtered, the filtrate was rotary evaporated, and passed through a silica gel column to obtain intermediate 2 with a HPLC purity of 99.4%;

[0061] (2) Preparation of Compound 2

[0062] 10mmol of the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com