Wastewater treatment method, and cross-flow membrane bioreactor ultrafiltration system used therein

A bioreactor and ultrafiltration system technology, which is applied in the field of cross-flow membrane bioreactor ultrafiltration system, can solve the problems of popularization and use of catering in difficult urban areas, poor catering wastewater treatment effect, and difficulty in meeting the needs of catering wastewater treatment. The effect of activated sludge concentration, cost saving and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

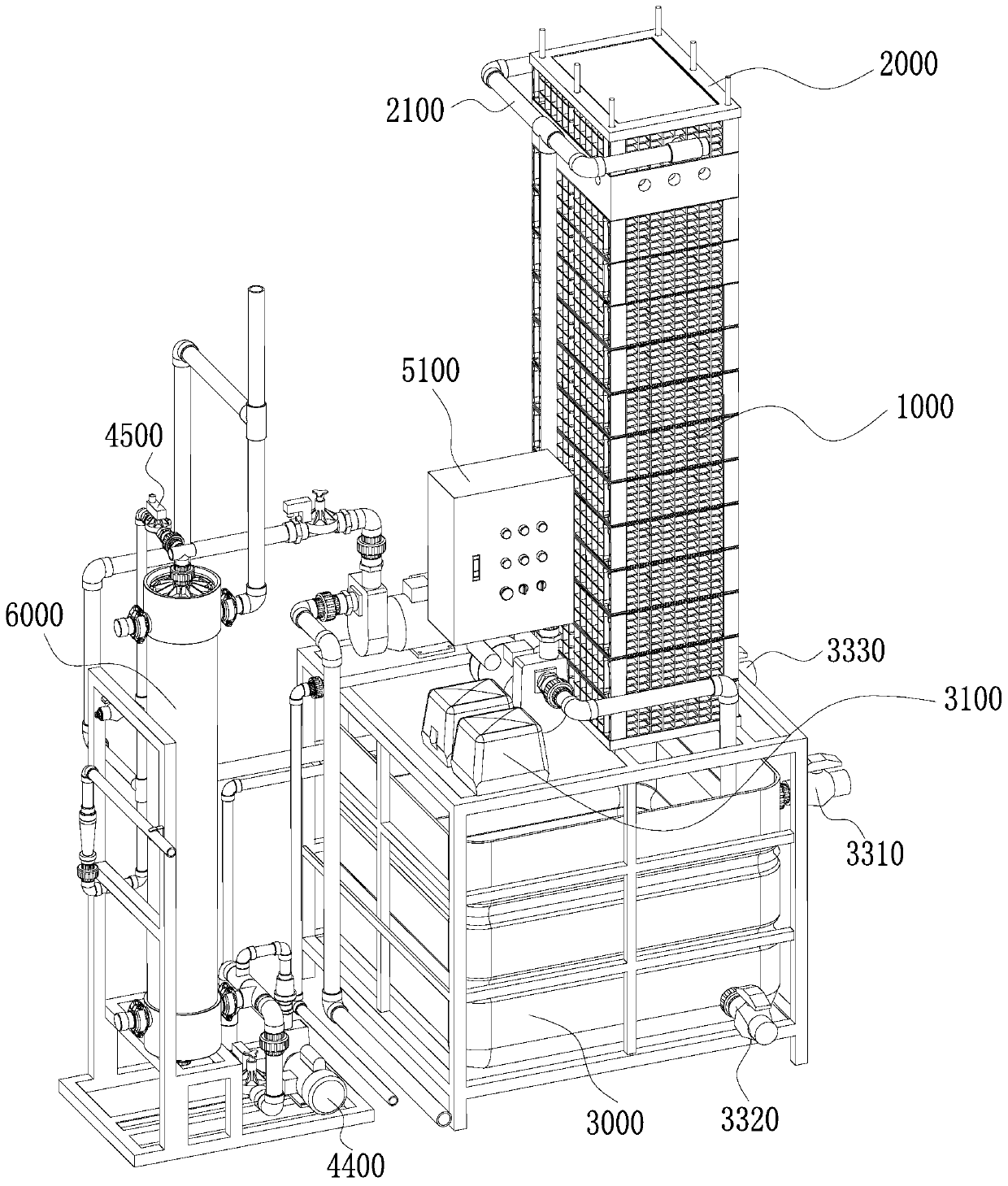

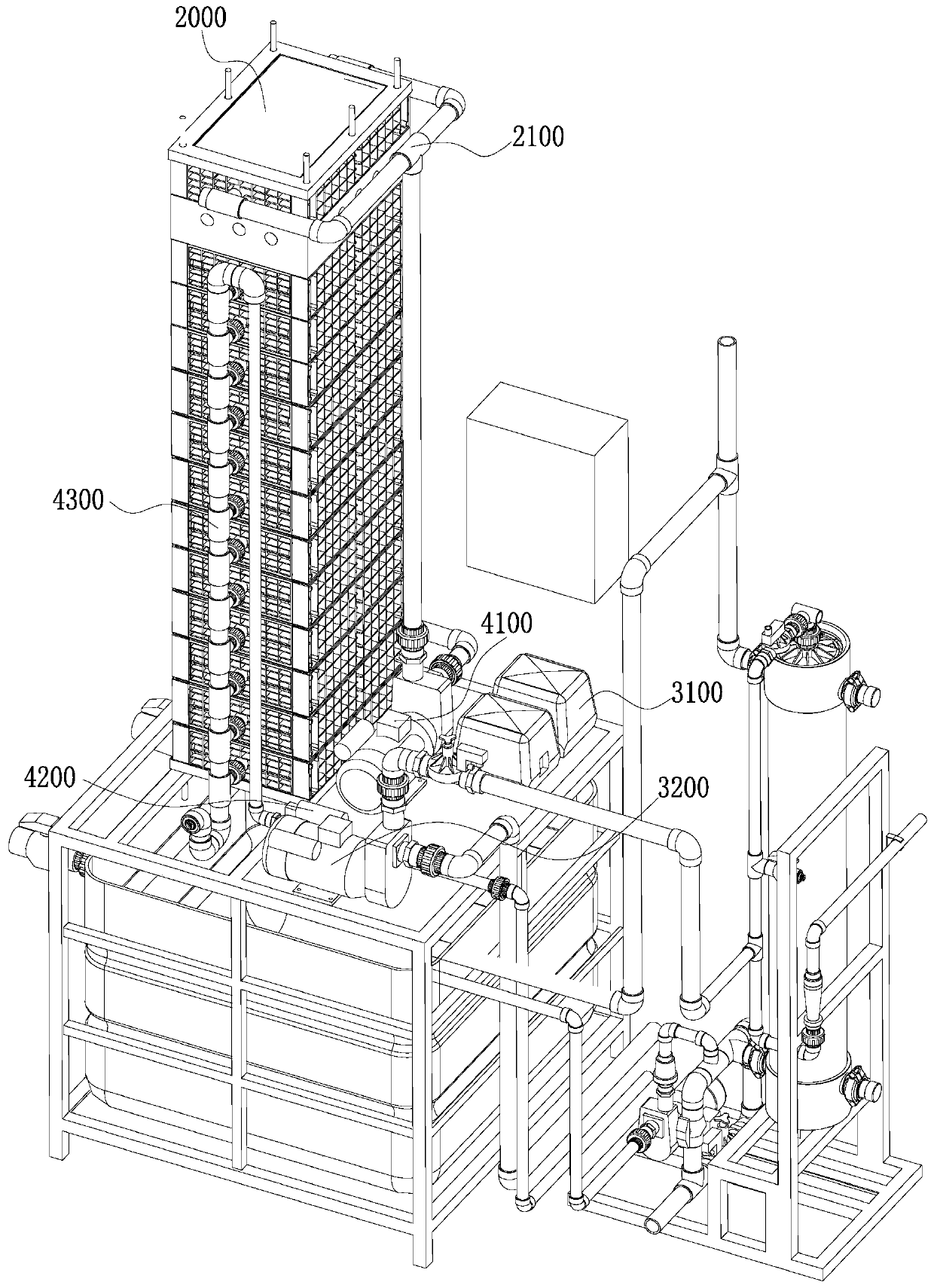

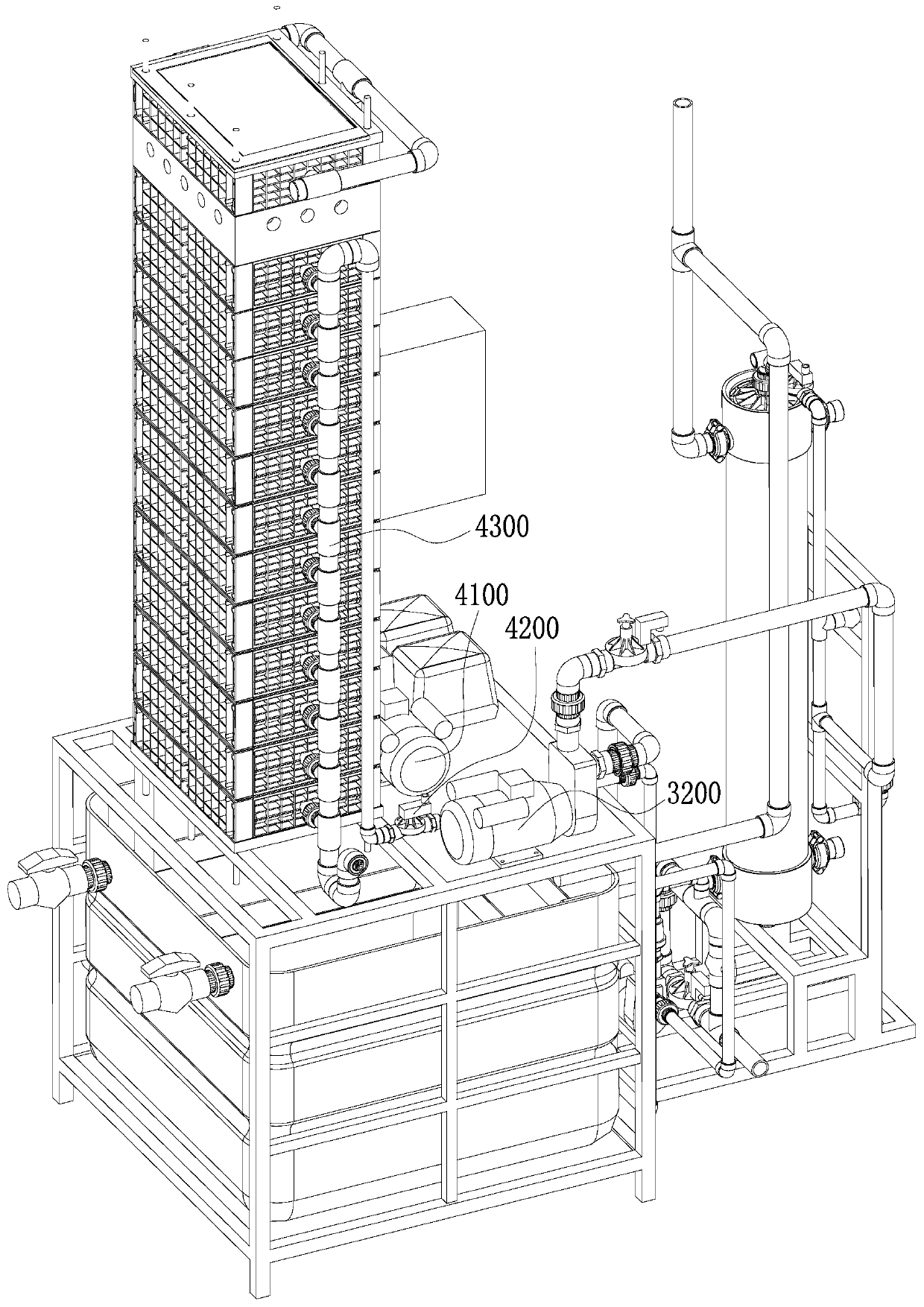

[0052] A cross-flow membrane bioreactor ultrafiltration system, such as Figure 1-3 As shown, it includes: ceramic membrane group 1000, spray device 2000, aerobic tank 3000, liquid system, central control system and flexible ceramic membrane filter device 6000.

[0053] The ceramic membrane group includes a ceramic substrate for the attachment and growth of microorganisms, the ceramic substrate is vertically arranged, and the surface of the ceramic substrate is provided with a plurality of pores, and at least one substrate pipeline is arranged inside the ceramic substrate, and the plurality of pores and The substrate is plumbed, as Figure 4 shown. It can be understood that the ceramic substrate can be a conventional hollow ceramic plate.

[0054] In this embodiment, the ceramic membrane group also includes a number of detachable assembled box-type ceramic membrane boxes, for example, including a frame that surrounds and fixes the ceramic substrate, such as Figure 5 As sho...

Embodiment 2

[0088] Adopt the cross-flow membrane bioreactor ultrafiltration system of embodiment 1 to carry out waste water treatment, comprise following operation:

[0089] 1. Aerobic box treatment process:

[0090] 1. Aeration treatment.

[0091] Through the aeration of the aeration device, the concentration of dissolved oxygen in the aerobic tank is increased, and aerobic microorganisms are multiplied. Part of the bred aerobic microorganisms remains in the aerobic tank to react with wastewater, aerobically degrades the pollutants, and the other Part of it adheres to and grows on the surface of the ceramic substrate along with the spraying process, forming a biofilm.

[0092] Second, the ceramic membrane group treatment process.

[0093] 1. The first liquid level (low liquid level) treatment process.

[0094] When the liquid level sensing device senses that the wastewater liquid level is at the first liquid level, that is, lower than the low liquid level, the central control system c...

Embodiment 3

[0109] The cross-flow membrane bioreactor ultrafiltration system of Example 1 was used, and the catering wastewater was treated according to the wastewater treatment method of Example 2.

[0110] The catering wastewater was taken for filtration, and the pre-treatment and post-treatment samples of different dates in 2018 were taken for testing. The results are shown in the table below.

[0111] Table 1. Effects of catering wastewater treatment on different dates

[0112]

[0113] Table 2. Catering wastewater treatment effect at different time points

[0114]

[0115] Note: COD refers to Chemical Oxygen Demand, chemical oxygen demand;

[0116] Raw water refers to the catering wastewater before treatment;

[0117] Biochemical water refers to the water after microbial oxidation and decomposition treatment and biofilm biochemical treatment;

[0118] Water produced by ceramic membrane refers to the purified water flowing out of the substrate pipeline of the ceramic membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Filter pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com