Injection molding process of salad plate

An injection molding process and injection molding technology, which is applied in the field of plastic product processing, can solve the problems of easy sticking or deformation of mold release, wavy disc surface, and low yield, so as to avoid sticking, prevent mucous membrane, and improve yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

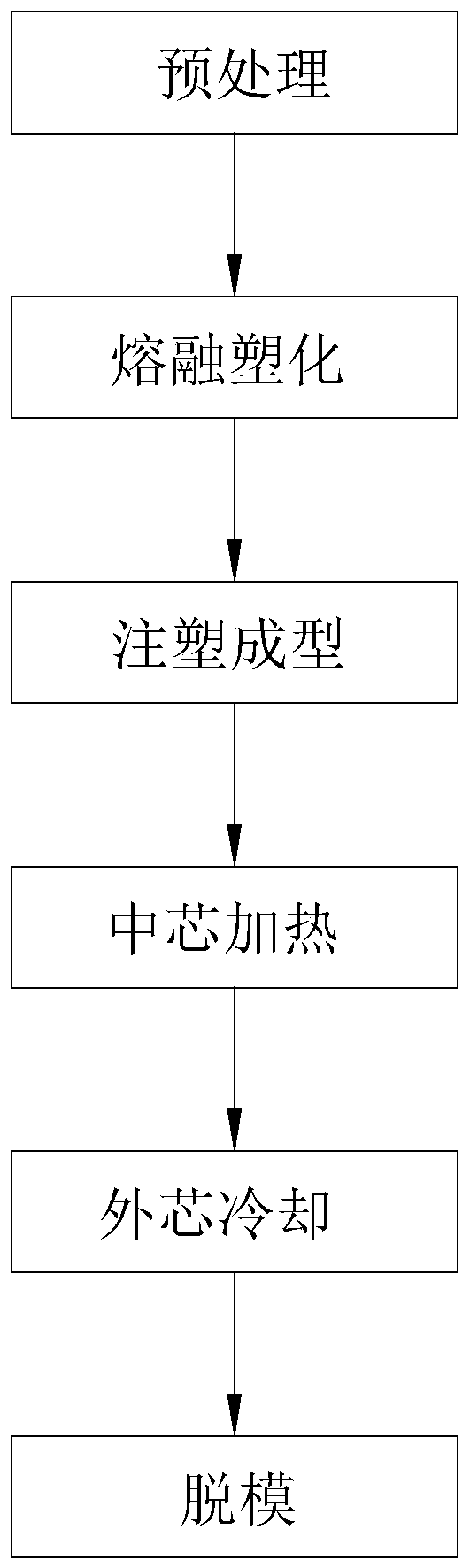

[0041] A kind of injection molding process of salad dinner plate, such as figure 2 shown, including the following steps:

[0042] S1. Pretreatment: Put the plastic PP to be injection-molded into a dryer, and use hot air to dry it, so that the plastic PP can be kept dry before molding to prevent mucous membrane during molding. Wherein, the drying temperature is controlled at 80° C., and the drying time is controlled at 2 hours.

[0043] S2. Melting and plasticizing: Put the dried plastic PP into the storage barrel of the injection molding machine and heat it to melt it.

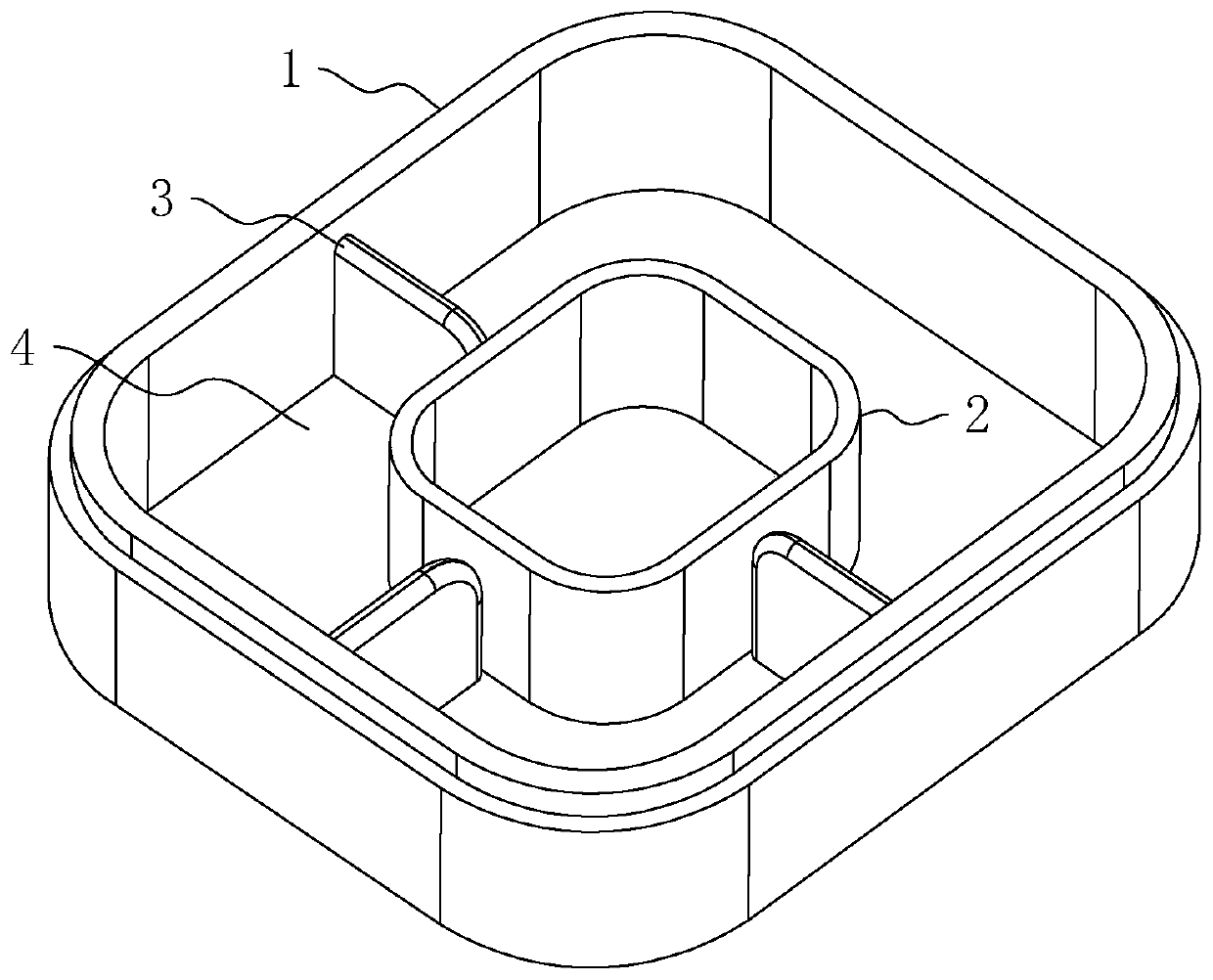

[0044] S3. Injection molding: the plastic PP in the molten state is injected into the core of the mold at an injection speed of 7mm / s through an injection device. Specifically, the core includes an outer core for forming the disc body and a central core for forming the central disk, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com