Trolley type handheld grinding machine

A grinding machine and trolley-type technology, which is applied in the direction of grinding racks, portable grinding machines, grinding machines, etc., can solve the problems of high work intensity and low efficiency, and achieve the effect of improving efficiency, low cost and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

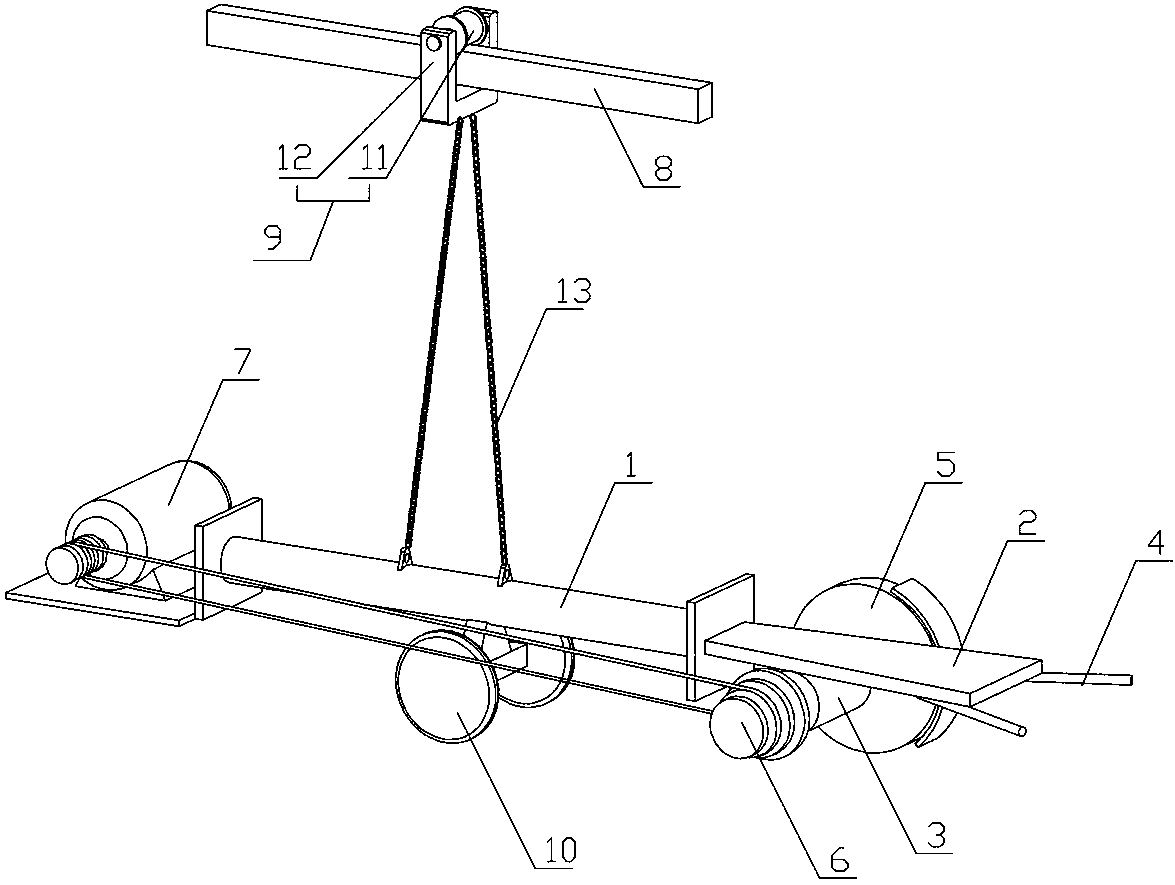

[0013] In this embodiment, a cart-type hand-held grinder has a balance rod 1. One end of the balance rod 1 is welded with a shaft sleeve 3 and a hand-held handle 4 in sequence through a connecting plate 2. The shaft sleeve 3 is sleeved with a rotating shaft. One end of the rotating shaft is connected with a grinding wheel 5, the other end of the rotating shaft is connected with a multi-slot speed-adjusting pulley 6, and a drive motor 7 is installed on the other end of the balance rod 1, and the driving motor 7 is connected with the multi-slot speed-adjusting pulley 6 and drives the grinding wheel 5. Rotating, a guide rail 8 is arranged above the balance rod 1, and a hanging wheel 9 is movably installed on the guide rail 8. The balance rod 1 is hung on the hanging wheel 9, and a pair of rollers 10 are symmetrically installed under the balance rod 1. .

[0014] In this embodiment, the multi-slot speed-adjusting pulley 6 has a conical structure, and the diameter of each slot grad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com