Deodorant for removing malodor generated in sludge drying, and preparation method and application thereof

A technology of sludge drying and deodorant, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of high cost of use, inability to analyze and reuse, high cost of treatment, etc., and achieve the goal of solving the problem of odor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

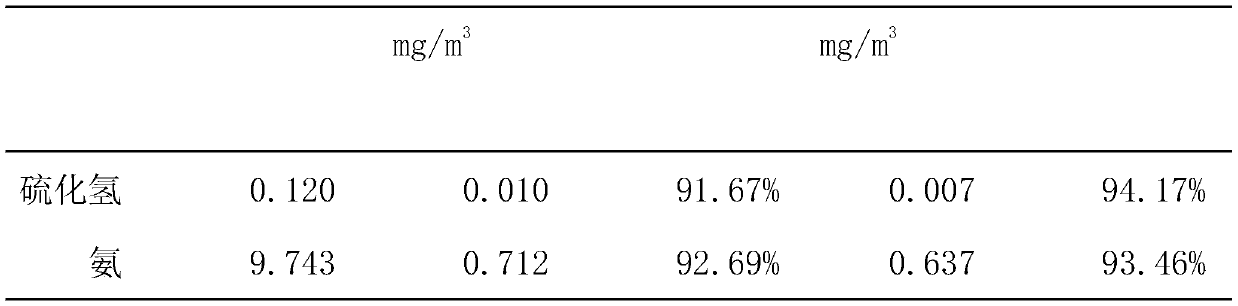

Examples

Embodiment 1

[0024] In a deodorant for removing foul odor produced by sludge drying, the composition consists of the following components in parts by weight:

[0025] Component 1, water 30%-98%;

[0026] Component 2, emulsifier 0.50%-20%;

[0027] Component 3, pH regulator 0.01%-30.00%;

[0028] Component 4, Moringa oleifera seed oil 1.00%-25.00%;

[0029] Component 5, preservative 0.0001-1%;

[0030] Component 6, Fragrance 0.0001-1%;

[0031] Component 7, thickener 0.0001-1%;

[0032] Component 8, pigment 0-1%.

[0033] The emulsifier is specifically one or more combinations of substances in the following categories: sorbitan stearate, sorbitan oleate, sorbitan cocoate, sorbitan olive oleate, sorbitan caprylate, Sorbitan laurate, sorbitan palmitate, octylphenol polyether-11, octylphenol polyether-9, nonylphenol polyether-11, nonylphenol polyether-9, polysorbate-20 , Polysorbate-21, Polysorbate-40, Polysorbate-60, Polysorbate-80, Polysorbate-85, PEG-40 Hydrogenated Castor Oil, PEG-6...

Embodiment 2

[0047] In a deodorant for removing foul odor produced by sludge drying, the composition consists of the following components in parts by weight:

[0048] Component 1, water: 96.33 parts;

[0049] Component 2, Sorbitan Laurate: 1 part;

[0050] Component 3, polysorbate-20: 0.4 part;

[0051] Component 4, potassium hydroxide: 0.01 part;

[0052] Component 5, Moringa oleifera seed oil: 2 parts;

[0053] Component 6, methylisothiazolinone: 0.01 parts;

[0054] Component 7, Carbomer: 0.15 parts;

[0055] Component 8, orange essence: 0.1 part.

[0056] Preparation process:

[0057] Ⅰ. Mix components 1 and 7 evenly, heat to 80°C, and set aside.

[0058] Ⅱ. Mix components 2, 3, and 5 evenly, heat to 80°C, and set aside.

[0059] III. Slowly add the mixture obtained in step II to step I, stir for 30 minutes until uniform, and homogenize for 10 minutes.

[0060] Ⅳ. Cool to 43°C, add components 6 and 8, and stir for 30 minutes until uniform.

[0061]Ⅴ. Add component 4 and stir ...

Embodiment 3

[0063] In a deodorant for removing foul odor produced by sludge drying, the composition consists of the following components in parts by weight:

[0064] Component 1, water: 95.99 parts

[0065] Component 2, Sorbitan Laurate: 1 part

[0066] Component 3, polysorbate-20: 0.4 parts

[0067] Component 4, sodium hydroxide: 0.01 part

[0068] Component 5, wing seed Moringa seed oil: 2 parts

[0069] Component 6, methyl p-hydroxybenzoate: 0.2 parts

[0070] Component 7, propyl p-hydroxybenzoate: 0.1 parts

[0071] Component 8, xanthan gum: 0.2 parts

[0072] Component 9, lavender essence: 0.1 parts

[0073] Preparation process:

[0074] Ⅰ. Mix components 1 and 8 evenly, heat to 80°C, and set aside.

[0075] Ⅱ. Mix components 2, 3, 5, 6, and 7, heat to 80°C, and set aside.

[0076] III. Slowly add the mixture obtained in step II to step I, stir for 30 minutes until uniform, and homogenize for 10 minutes.

[0077] Ⅳ. Cool to 43°C, add component 9, and stir for 30 minutes unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com