Factory building welding exhaust gas purification apparatus

An exhaust gas purification device and purification device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inconvenient movement, affecting the aesthetics of the device, and the inability of the suction arm to accommodate the welding fume purifier, so as to achieve convenient operation , simple structure, and the effect of preventing the reduction of filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

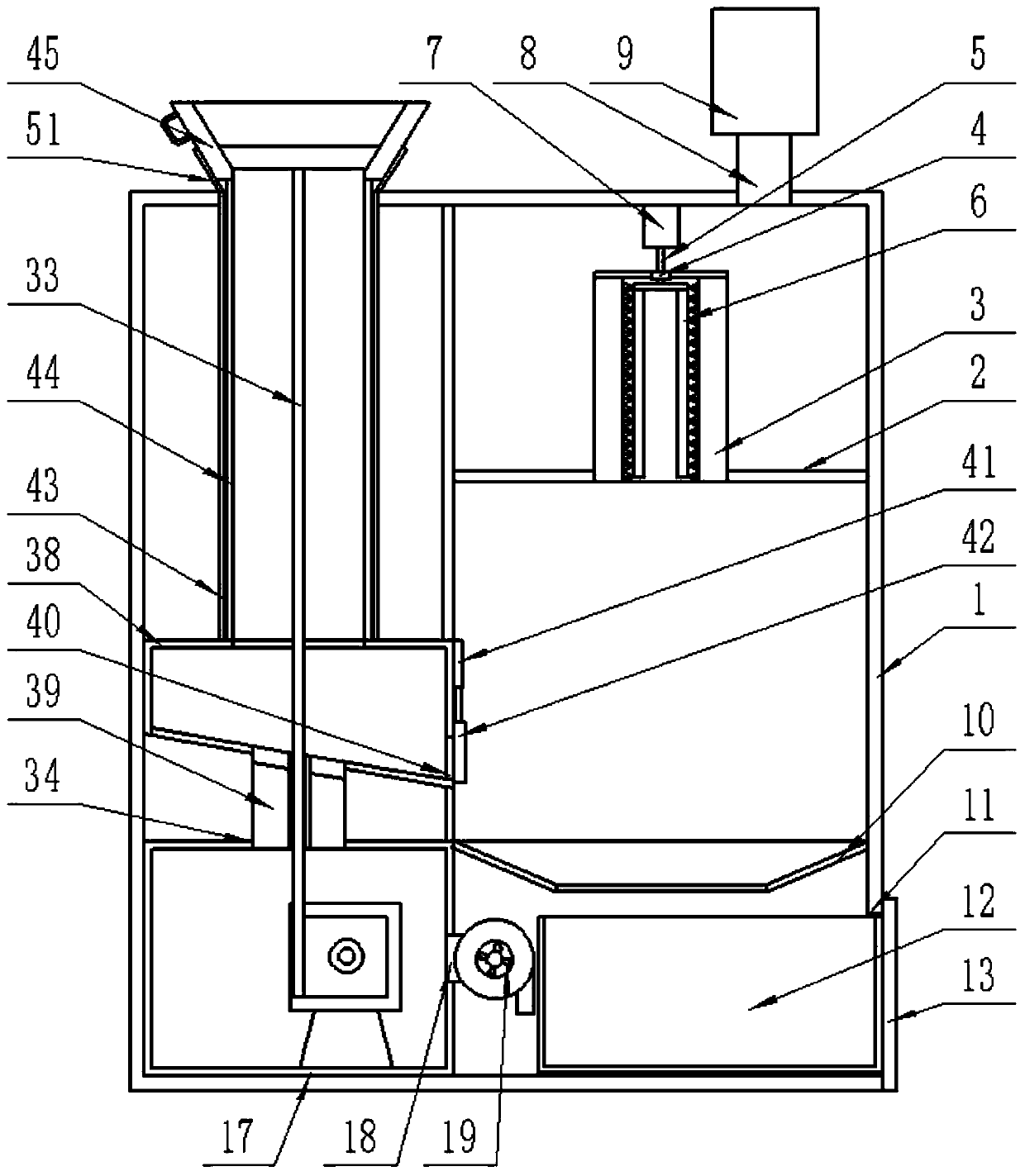

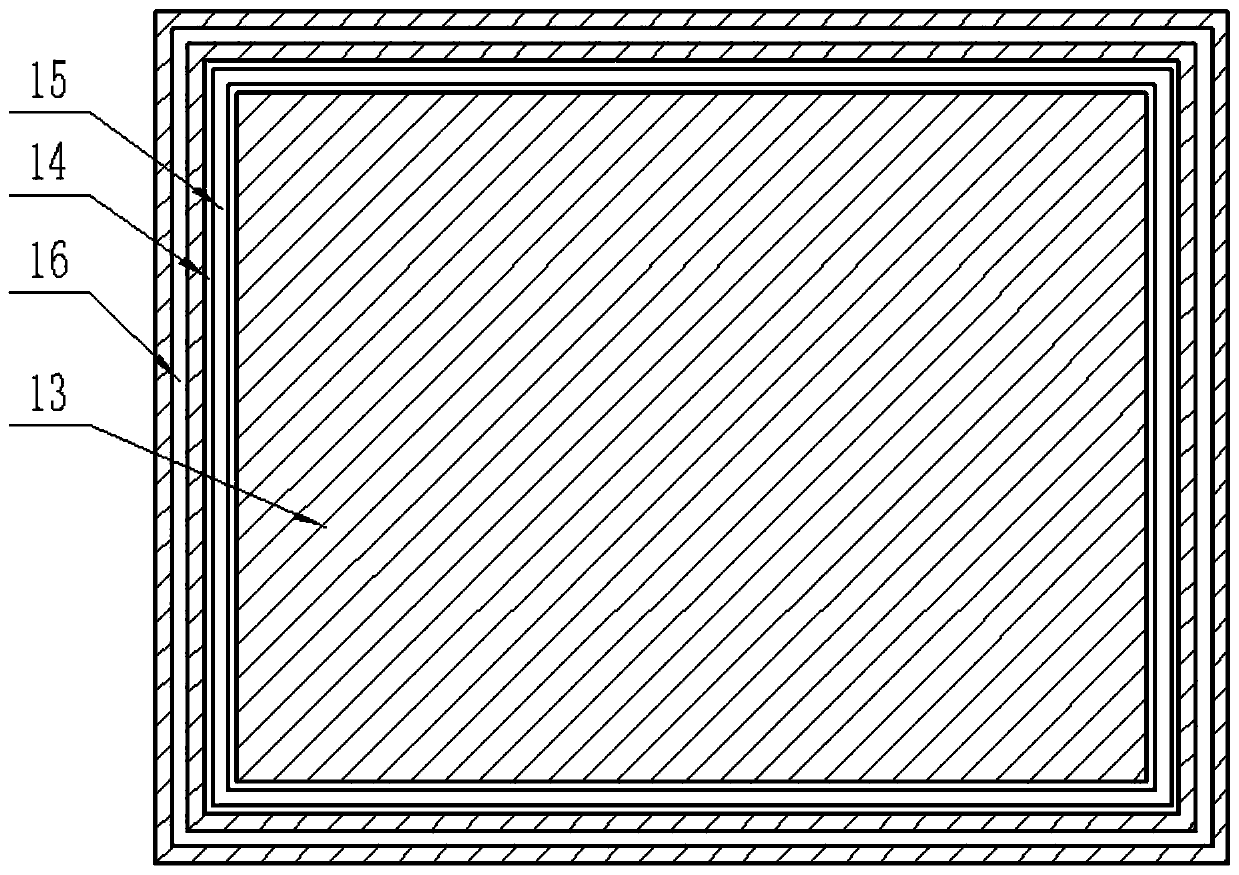

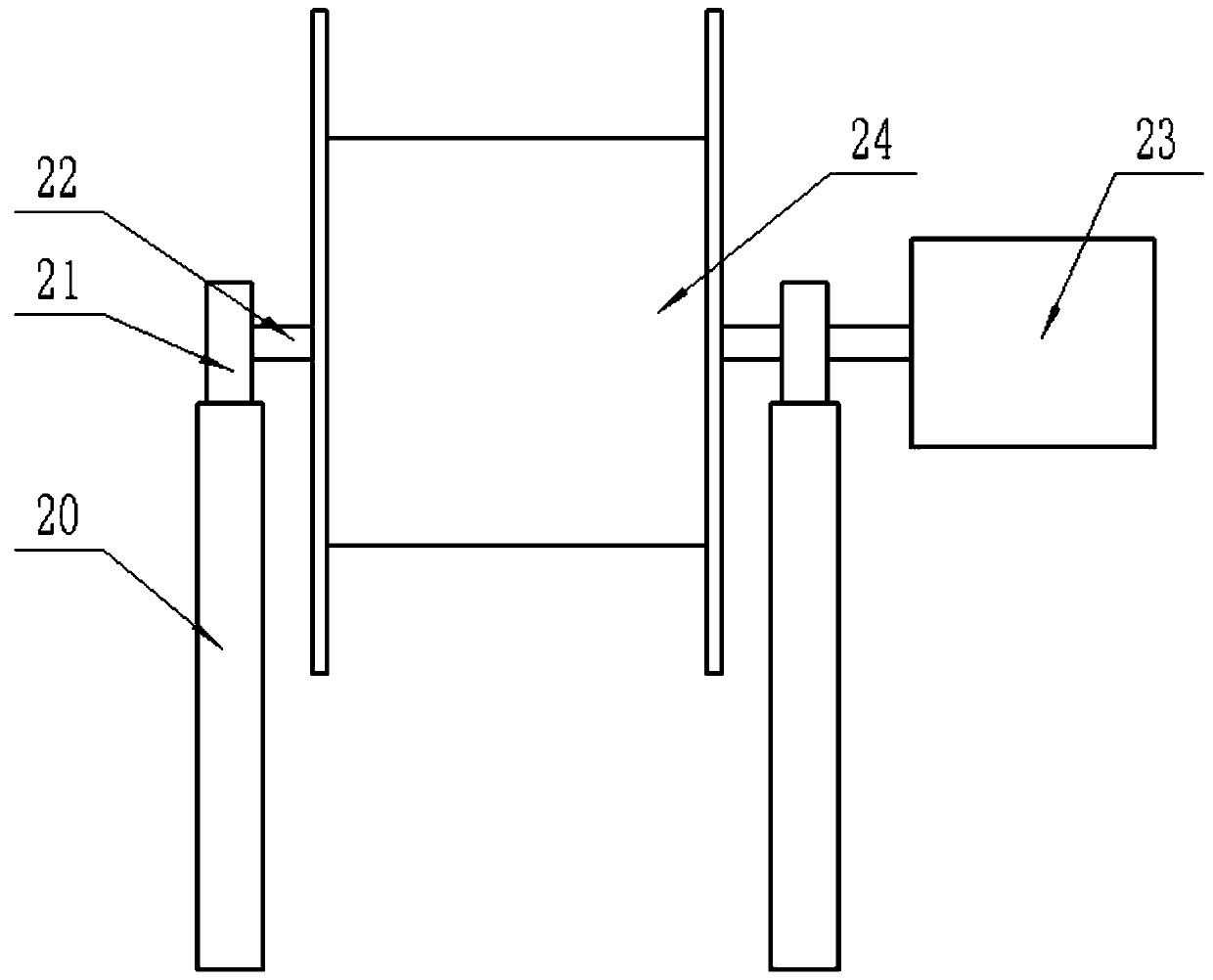

[0025] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-7 As shown, in this implementation:

[0026] First, connect the device to an external power source, and when the device needs to be used, move the device to the place of use;

[0027] Now the staff takes off the exhaust cover 45 manually, and now the exhaust cover 45 drives the universal hose 44 to pull out, and simultaneously drives the connecting short rod chain 33 to start to stretch out from the square drum 24, so that the universal hose 44 and the connecting short rod chain 33 stretch out the welding fume purifier 1, and after the exhaust hood 45 is moved to the vicinity of the welding place, at this time, the circular sealing plate 48 is manually rotated to make the gap between the fan-shaped filter port 49 and the fan-shaped bracket 46 At this time, the mute fan 9 is controlled to start working, and at the same time, the electric telescopic rod 41 is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com