Vacuum pre-cooling device for assisting production of low temperature cooked meat products

An auxiliary device and pre-cooling technology, which is applied in the direction of food ingredients as color, food science, etc., can solve the problems of a* value reduction, sample L* value increase, etc., to reduce water loss, reduce water loss, and reduce time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

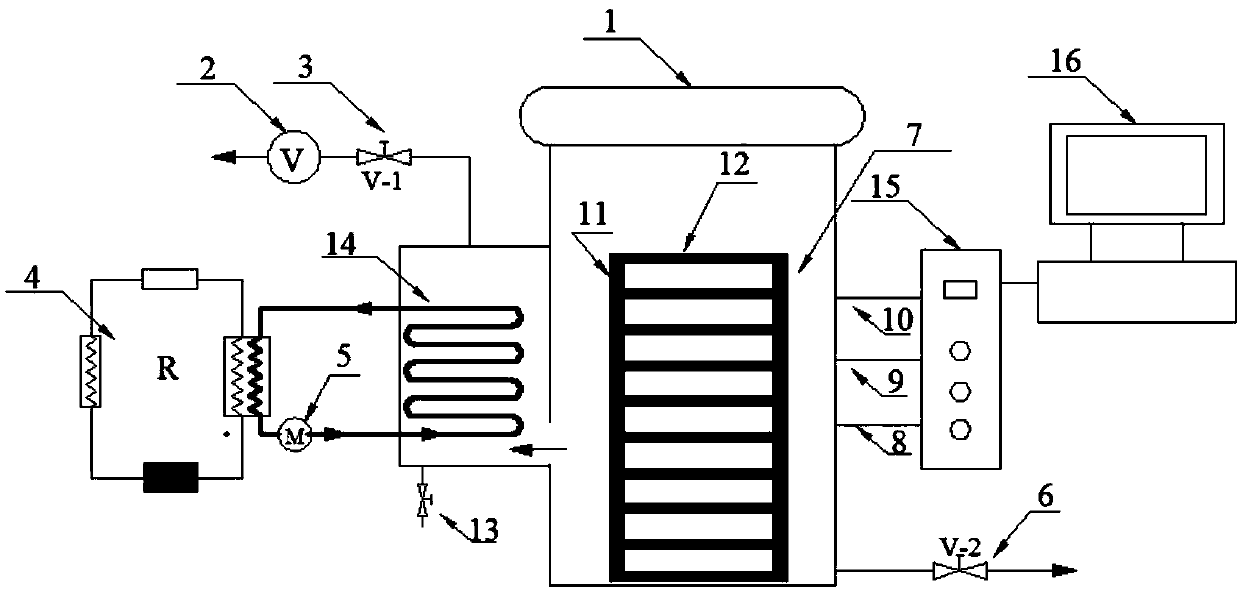

[0037] The auxiliary device group 7 involved in the present invention is used together with the vacuum precooling combination for the precooling of Western-style ham. Among them, the vacuum pre-cooler includes a condensation system, a vacuum system, a data collection system, and a data processing and operating system, which are connected in sequence, including a refrigeration unit 4, a condenser 14, a cryogenic liquid circulation pump 5, a vacuum box 1, a vacuum pump 2, Pneumatic valve 3, exhaust valve 6, drain valve 13, weight sensor 8, pressure sensor 9 and temperature sensor 10, data processor 15 and computer 16; the condensing system is composed of refrigeration unit 4, cryogenic liquid circulation pump 5 and condenser 14 The vacuum system consists of a vacuum box 1 and a vacuum pump 2; the data collection system consists of a weight sensor 8, a pressure sensor 9 and a temperature sensor 10; the data processing and operating system consists of a data processor 15 and a comp...

specific Embodiment 1

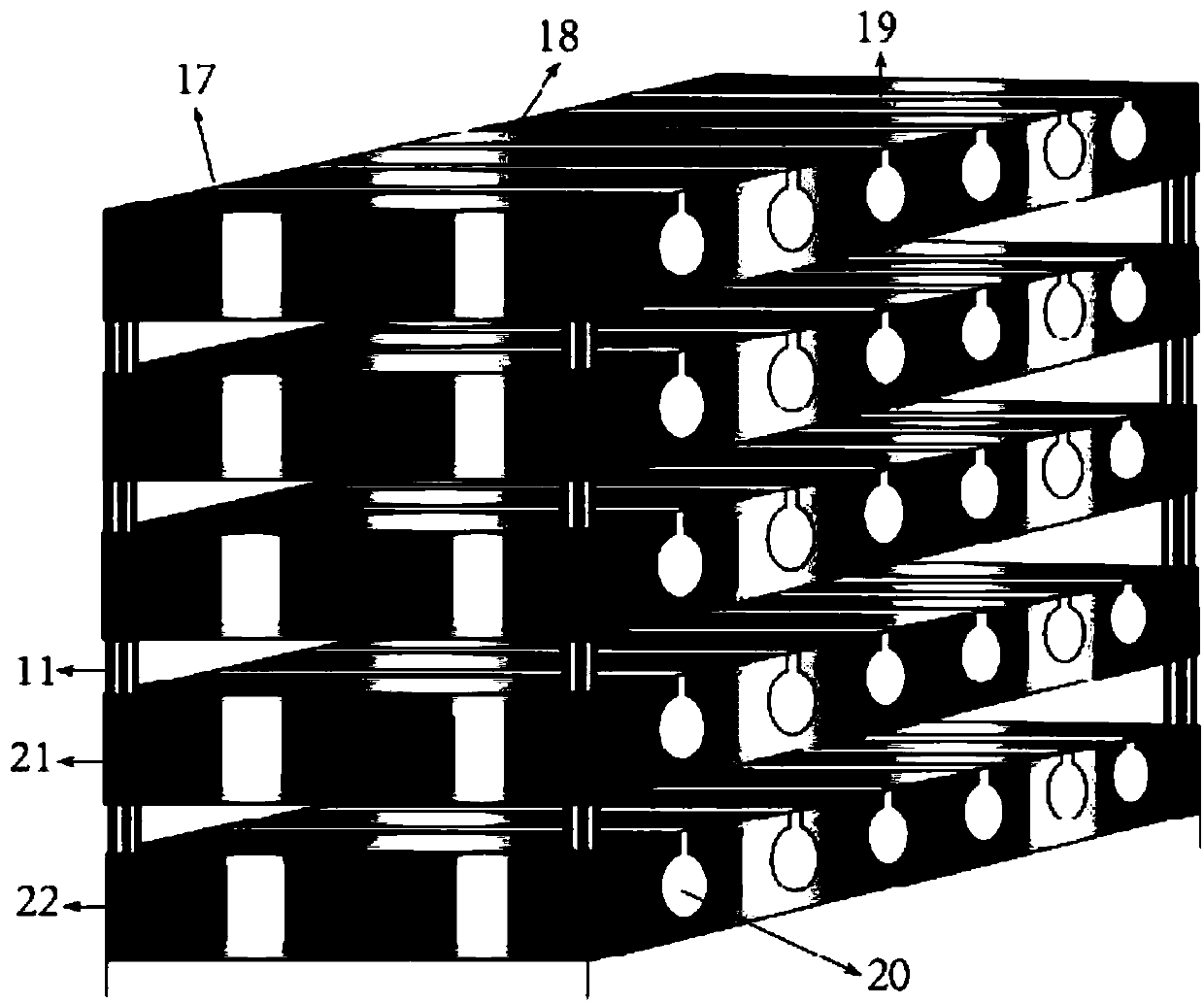

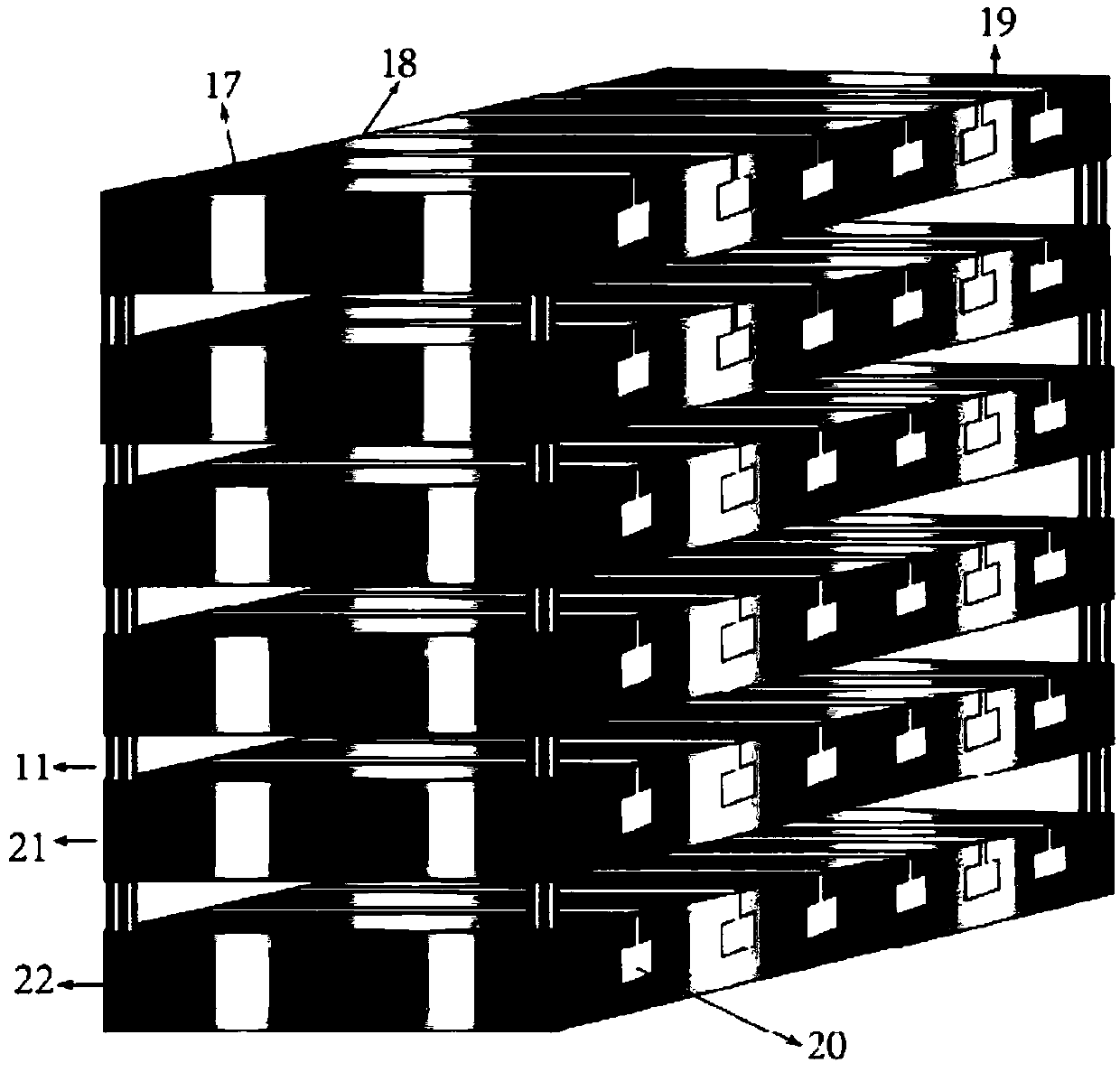

[0041] Western-style ham diameter is 95mm, height is 500mm in concrete embodiment 1 (being " design device auxiliary vacuum precooling " in the table); The diameter of hollow cylinder is 100mm, the height of hollow cylinder is 500mm; Hollow cuboid height is 150mm, The width is 500mm, the length is 900mm (place 6 Western-style hams); the length of the built-in small cuboid slot is 500mm, the height is 25mm, and the width is 5mm; the distance between the hollow cylinders on the hollow cuboid is 50mm, and the distance between the upper and lower planes of the hollow cuboid 25mm respectively.

Embodiment 2

[0043] (1) Cook the Western-style ham so that its central temperature is 72°C, take out and remove its packaging material to obtain Western-style ham (cylindrical), the porosity of the Western-style ham is 0.38%, the diameter is 95mm, and the length is 500mm. Wrap the Western-style ham in two layers of damp gauze.

[0044] (2) Put the Western-style ham wrapped in two layers of wet gauze into the cleaned, pre-cooled and sterilized device (stuffed into a hollow cylinder).

[0045] (3) Put the above samples together into the vacuum box of the vacuum pre-cooler, insert the temperature probe into the geometric center of the Western-style ham, close the vacuum box door of the vacuum pre-cooler, turn on the vacuum pump, and set the pressure drop rate coefficient of the vacuum pump to Adjusted to 0.21min -1 , Start the condenser after 30s, and set the condensing temperature to -10±2°C, and the final pressure value should not be lower than 6.5mbar.

[0046] (4) The operating conditio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com