Separator and non-aqueous electrolyte battery

A non-aqueous electrolyte and diaphragm technology, applied in the field of non-aqueous electrolyte batteries, can solve problems such as limited working opportunities, achieve the effect of suppressing characteristic degradation and reducing the occurrence of adverse conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

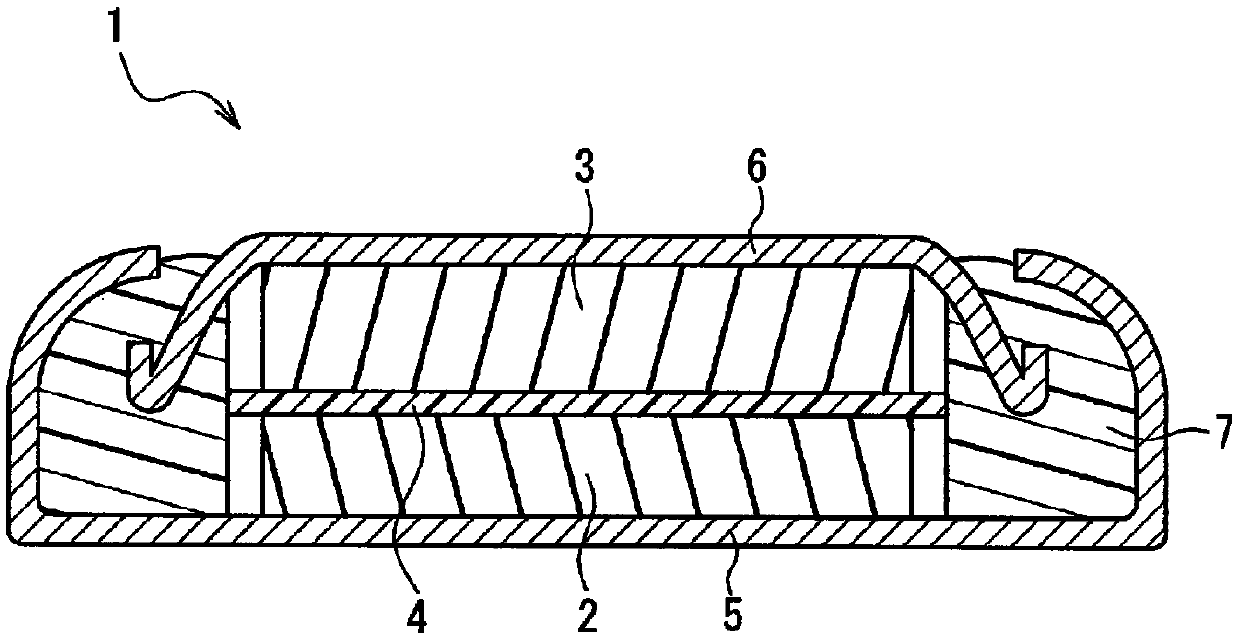

Embodiment 1

[0112] As the exterior material of the battery, a stainless steel airtight can with a polyphenylene sulfide gasket attached to an open end and a stainless steel exterior can were prepared. The negative electrode was crimped on the inner surface of the airtight can, and two separators punched into a circular shape with a diameter of 19 mm were laminated on the negative electrode, and then the positive electrode was laminated on the separator. A stack of negative electrode / separator / positive electrode was placed in a sealed can. Next, inject the non-aqueous electrolytic solution into the airtight can, absorb the liquid into the diaphragm, cover the outer can, and seal it by fastening it to obtain figure 1 A coin-shaped non-aqueous electrolyte battery with a diameter of 20 mm and a height of 3.2 mm of the structure shown.

[0113] figure 1 For schematically showing the longitudinal sectional view of the non-aqueous electrolyte battery of embodiment 1, in the non-aqueous electro...

Embodiment 2

[0116] A coin-shaped non-aqueous electrolyte battery was obtained in the same manner as in Example 1, except that one sheet of the separator of Production Example 2 punched out into a circle was used for assembling the battery.

Embodiment 3

[0118] A coin-shaped non-aqueous electrolyte battery was obtained in the same manner as in Example 1, except that one sheet of the separator of Production Example 3 punched out into a circle was used for assembling the battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com