Non-PEDOT: PSS inverted series quantum dot light emitting device and preparation method thereof

A quantum dot light-emitting and quantum dot technology, which is applied in the field of new display device manufacturing, can solve the problems of low device efficiency and repeatability, device stability influence and reduction, etc., to improve external quantum efficiency, improve stability, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

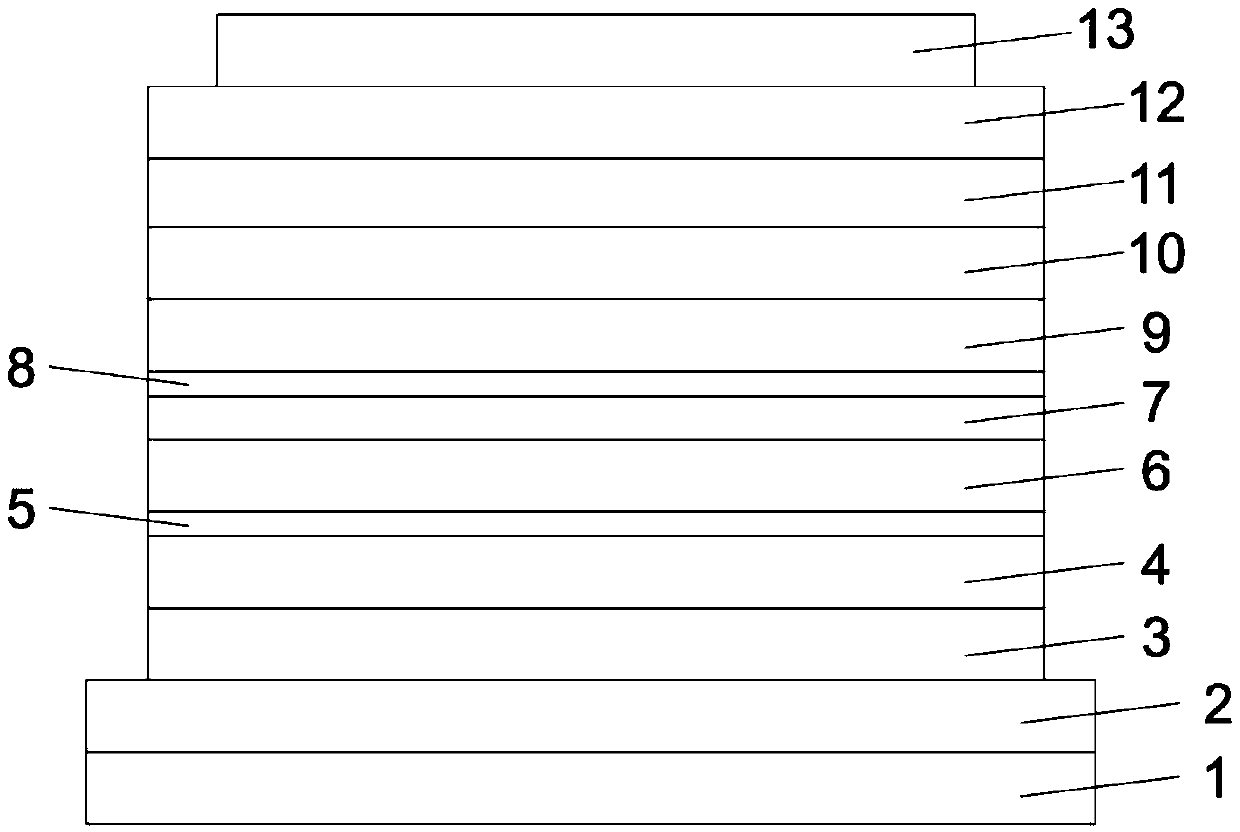

[0052] In this example, see figure 1 , a non-PEDOT:PSS inverted series quantum dot light-emitting device, from bottom to top, a base 1, a first light-emitting unit, a second light-emitting unit, and an anode 13 are formed into an inverted series light-emitting device structure, and the base 1 is provided with an ITO thin film cathode 2; The first light-emitting unit is composed of the first electron transport layer 3, the first quantum dot light-emitting layer 4, the first interface modification layer 5, the first hole transport layer 6 and the first hole injection layer 7 from bottom to top. Form the first light-emitting unit structure; the second light-emitting unit has a second interface modification layer 8, a second electron transport layer 9, a second quantum dot light-emitting layer 10, a second hole transport layer 11 and a second hole injection layer 12 The layers of each layer form the second light-emitting unit structure from bottom to top; the anode 13 is arranged ...

Embodiment 2

[0085] This embodiment is basically the same as Embodiment 1, especially in that:

[0086] In this embodiment, the first hole injection layer 7 is a PMA film with a thickness of 10nm; the second electron transport layer 9 is a zinc oxide film with a thickness of 65nm; the second interface modification layer 8 is made of metal The interface layer film, the thickness of the metal interface layer film is 5nm, and the metal interface layer film is a composite film of metal-metal shallow metal oxide gradient material with metal as the matrix, thereby forming a PMA film / metal interface layer film / zinc oxide A composite connection structure in the form of a sandwich composed of thin films connects two electroluminescence units in series. The metal interface layer film adopts nano-Al film, the metal Al interface layer film and its surface layer AlO x Oxide film formation Al:AlO x Gradient material composite film. The thickness of the ITO thin film cathode 2 is 150nm; the thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com