Novel water level sensor on expansion water tank used for automobile

A technology of water level sensor and expansion water tank, applied in the direction of float level indicator, machine/engine, engine cooling, etc., can solve the problems of high PPM, water tank leakage, high cost, and meet the requirements of anti-filling, preventing leakage and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

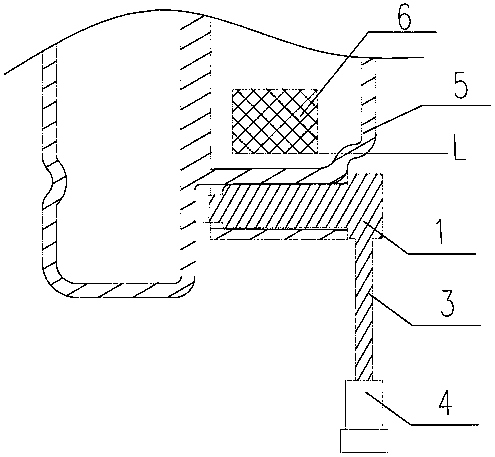

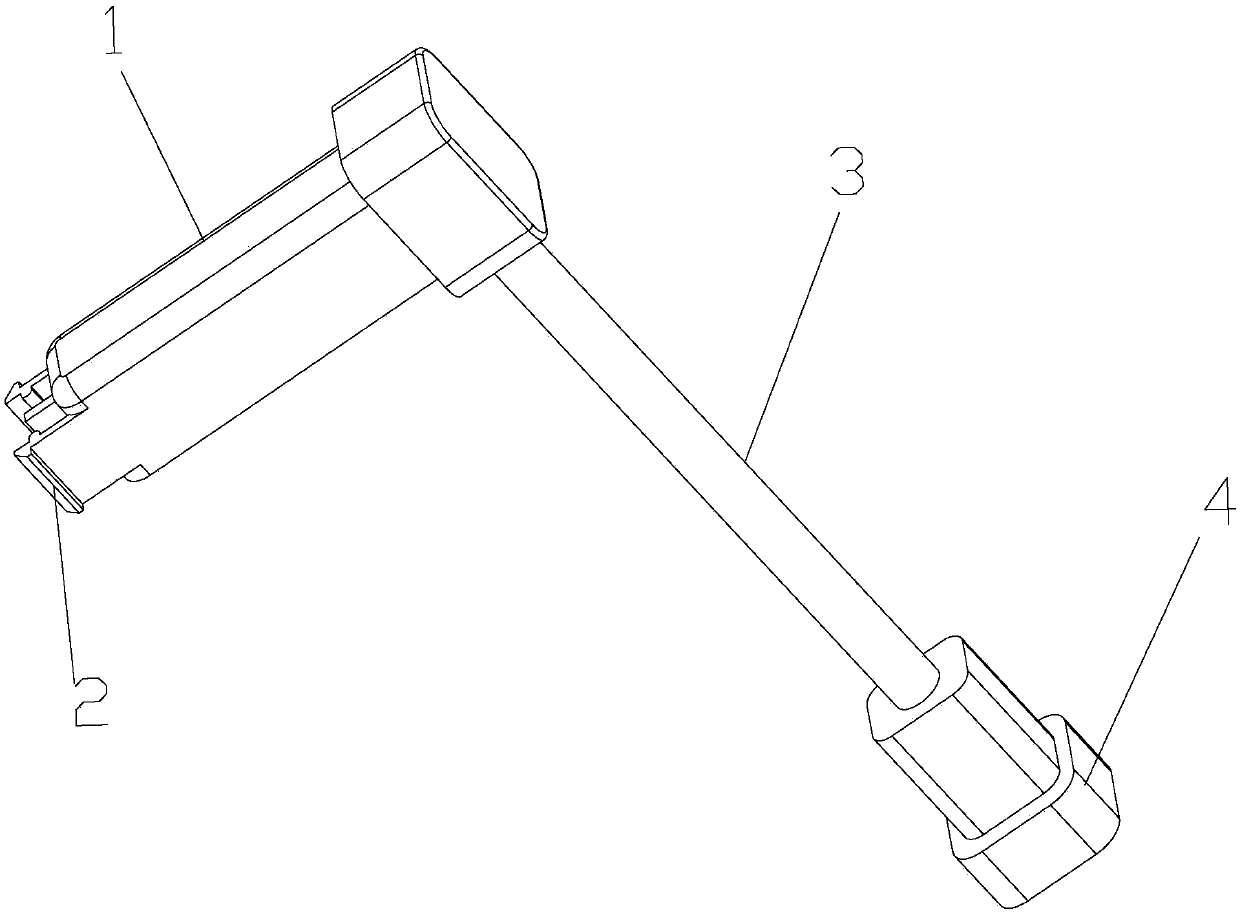

[0023] Such as Figure 1-2 As shown, a novel water level sensor on an expansion water tank for an automobile includes a sensor body, the sensor body is in an "L" shape, and claws 2 are provided on both sides of the end of the sensor body transverse portion 1, so that The end of the vertical part 3 of the sensor body is provided with a plug 4, the vertical part 3 of the sensor body is provided with a wiring harness, and the vertical part 3 of the sensor body and the plug 4 are connected by a wiring harness;

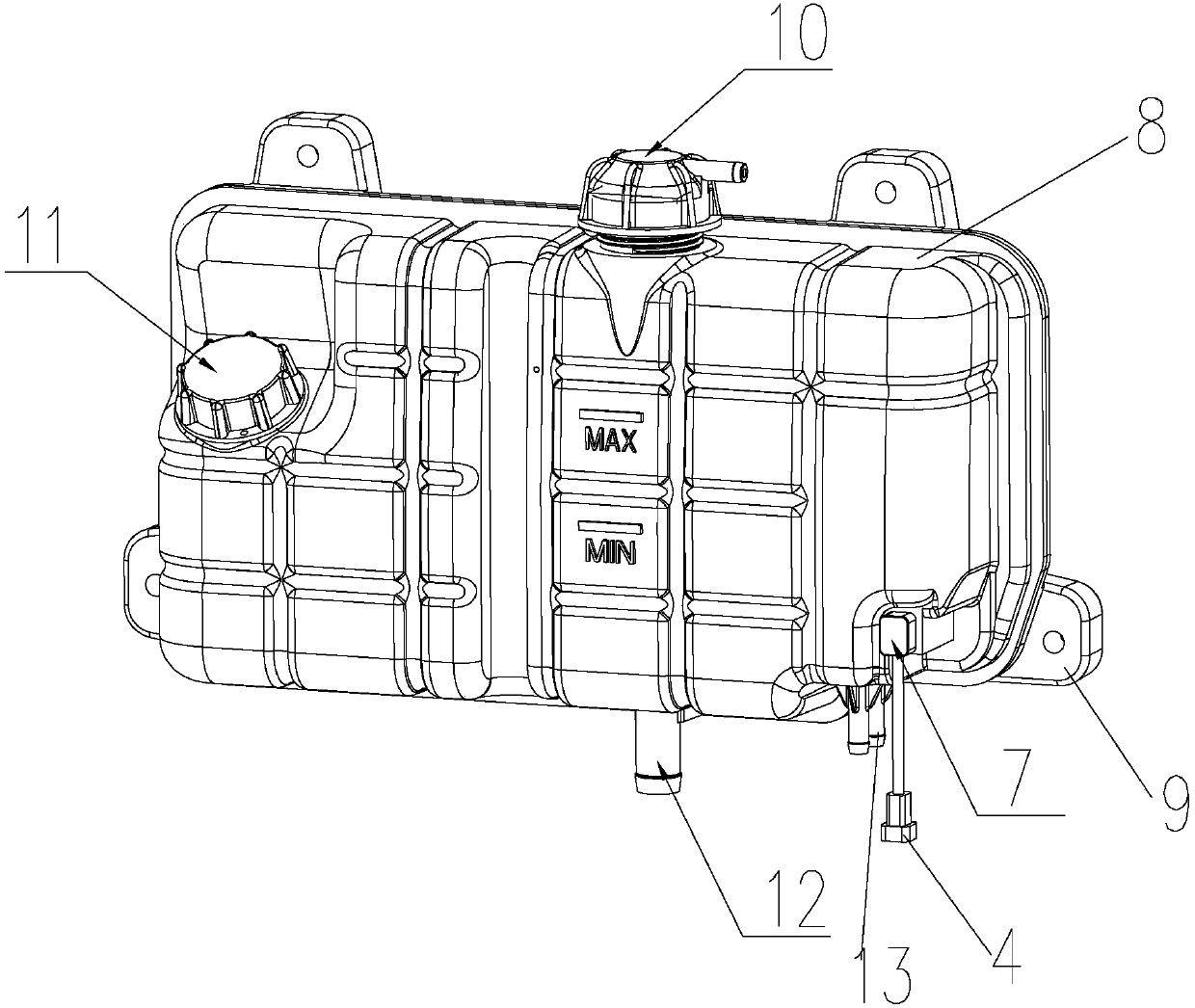

[0024] The claws 2 and the slots 7 of the expansion tank are clamped and fixed on the outside, and the expansion tank includes an upper box 8 and a lower box 9, and the upper box 8 and the lower box 9 are welded on Together, a pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com