Crude oil demulsifier for low temperature

A crude oil demulsifier and demulsifier technology, used in chemical dehydration/demulsification, petroleum industry, treatment of hydrocarbon oil, etc., can solve problems such as inability to dehydrate and demulsification, difficulty in dehydration of crude oil, and complex structural components of crude oil emulsions , to achieve good flocculation and coalescence ability, good wetting ability, good demulsification effect

Inactive Publication Date: 2019-04-26

CHINA PETROLEUM & CHEM CORP +1

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

With the decrease of oil temperature year by year, coupled with the implementation of enhanced oil recovery measures such as water injection, acidification, profile control, etc., the structural components of crude oil emulsion are becoming more and more complex, and the dehydration of crude oil is becoming more and more difficult. crude oil from different reservoirs, so a single demulsifier cannot fully meet these needs

Northeast, Xinjiang, Yanchang Oilfield, Changqing Oilfield and other oilfields often require crude oil production fluid to be kept at 25-30°C due to their own climate reasons, the actual situation of crude oil demulsification devices in oil production stations, the actual demulsification temperature of produced fluid, and processing costs. Demulsification under low temperature conditions, most domestic commercially available crude oil demulsifiers cannot effectively dehydrate and demulsify under this condition

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1-6

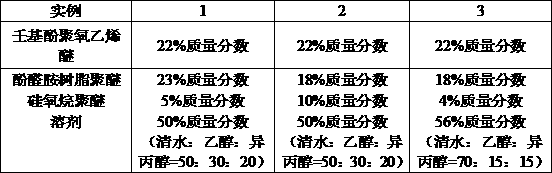

[0017] Table 1 Crude oil demulsifier formula for low temperature

[0018]

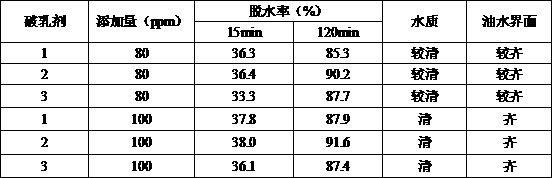

[0019] example evaluation method

[0020] Evaluation of dehydration effect

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a crude oil demulsifier for the low temperature. The crude oil demulsifier is prepared from the following components: nonylphenol polyoxyethylene ether, phenolic aldehyde amine resin polyether, siloxane polyether and a solvent. The nonylphenol polyoxyethylene ether in the compositions of the crude oil demulsifier can achieve a good basic dehydration effect on conventionalcrude oil produced fluid, the phenolic aldehyde amine resin polyether is high in molecular weight and high in lipophilicity, the dissolved quantity in an oil phase is greater than the dissolved quantity in a water phase, the phenolic aldehyde amine resin polyether has the good wetting ability and the flocculation and coalescence abilities, the siloxane polyether can achieve demulsification at thelow temperature of 25-30 DEG C, compared with the mode of separately using a polyester surfactant, the additive amount is decreased by 50% or above, the dehydration rate is high, the demulsification effect is good, and the comprehensive cost is lowered.

Description

technical field [0001] The invention relates to a crude oil demulsifier for low temperature, in particular to a crude oil demulsifier for gathering and transportation, and belongs to the technical field of oil field chemicals. Background technique [0002] With the increasing difficulty of oil extraction and the injection of various oil recovery additives, the water content of crude oil increases significantly after enhanced water injection and oil recovery, mostly in the form of oil-water emulsion. Crude oil production fluid contains a large amount of water, salt and other impurities, which brings great inconvenience to crude oil gathering and transportation, and must be dehydrated. Therefore, it is urgent to develop a crude oil demulsifier with strong demulsification ability and high broad-spectrum. [0003] Crude oil demulsifier refers to the separation of oil-water emulsion into water and oil through the physical and chemical action of demulsifier, so as to realize the d...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10G33/04

CPCC10G33/04C10G2300/1033

Inventor 杨智中袁俊秀朱魁

Owner CHINA PETROLEUM & CHEM CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com