Temporary plugging agent and preparation method and application thereof

A technology of temporary plugging agent and clay stabilizer, applied in the field of temporary plugging agent and its preparation, can solve the problems of poor oil solubility, low recovery rate, large formation damage, etc., and achieve strong adhesion performance, good plugging effect and state stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

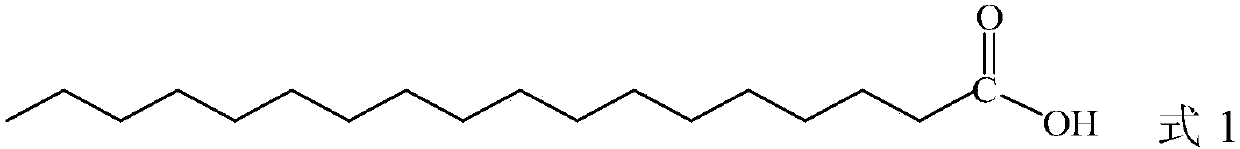

[0061] The temporary plugging agent in this example is suitable for reservoirs with a temperature of 50°C, and includes the following components in terms of weight percentage:

[0062] 1. Inorganic salt (NaCl): 34%;

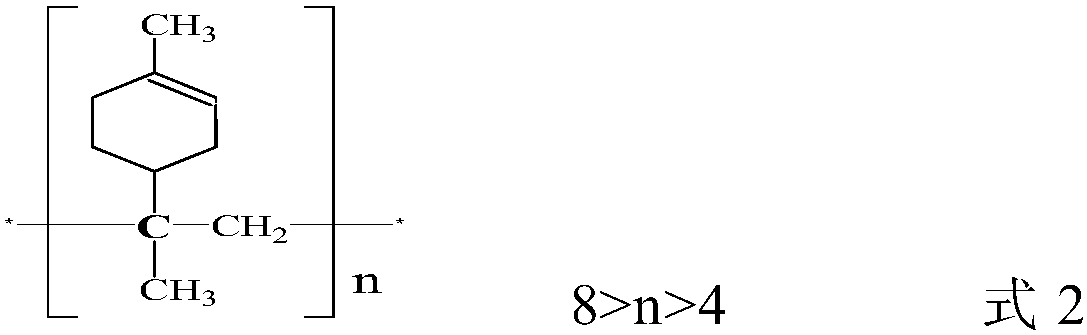

[0063] 2. Terpene resin T-80: 53%;

[0064] 3. Stearic acid (octadecanoic acid): 12%;

[0065] 4. Clay stabilizer (003-A) 1%;

[0066] The sum of the weight percentages of each component is 100%.

[0067] This temporary blocking agent can be prepared according to the following preparation method:

[0068] 1) Under stirring, add the above-mentioned raw materials in the reaction kettle according to the above-mentioned ratio to produce a mixture;

[0069] 2) Heat the mixture to 110°C (measured with a 30-200°C thermometer), and react under stirring for 1-2h, then stop the reaction;

[0070] 3) Using SE series screw extrusion granulator, the reactant wet material obtained in 2) is transported to the screw extrusion granulator at a temperature of 5-10°C higher tha...

Embodiment 2

[0083] The temporary plugging agent in this example is suitable for reservoirs with a temperature of 60°C, and includes the following components in terms of weight percentage:

[0084] 1. Inorganic salt (NaCl): 34%;

[0085] 2. Terpene resin (T-80): 57%;

[0086] 3. Stearic acid (octadecanoic acid): 8%;

[0087] 4. Clay stabilizer (003-A) 1%;

[0088] The sum of the weight percentages of each component is 100%.

[0089] This temporary blocking agent can be prepared according to the following preparation method:

[0090] 1) Under stirring, add the above-mentioned raw materials in the reaction kettle according to the above-mentioned ratio to produce a mixture;

[0091] 2) Heat the mixture to 115°C (measured with a 30-200°C thermometer), react under stirring for 1-2h, and then stop the reaction;

[0092] 3) Using SE series screw extrusion granulator, the reactant wet material obtained in 2) is transported to the screw extrusion granulator at a temperature of 5-10°C higher th...

Embodiment 3

[0105] The temporary plugging agent in this example is suitable for reservoirs with a temperature of 70°C, and includes the following components in terms of weight percentage:

[0106] 1. Inorganic salt (NaCl): 34%;

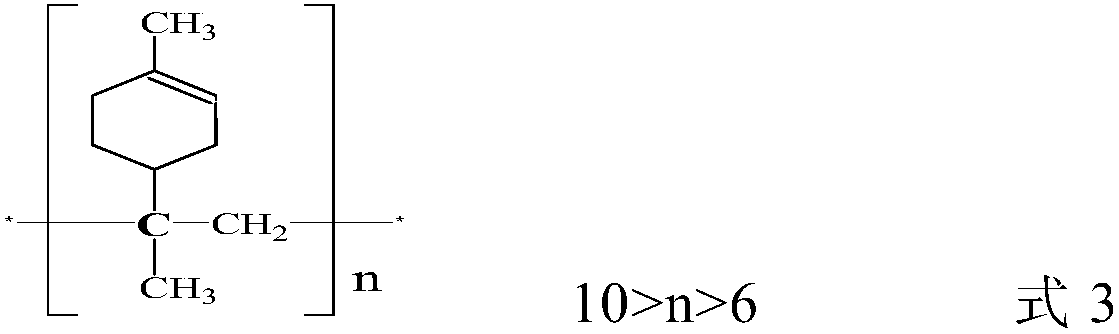

[0107] 2. Terpene resin T-100: 57%;

[0108] 3. Stearic acid (octadecanoic acid): 8%;

[0109] 4. Clay stabilizer (003-A) 1%

[0110] The sum of the weight percentages of each component is 100%.

[0111] This temporary blocking agent can be prepared according to the following preparation method:

[0112] 1) Under stirring, add the above-mentioned raw materials in the reaction kettle according to the above-mentioned ratio to produce a mixture;

[0113] 2) Heat the mixture to 120°C (measured with a 30-200°C thermometer), react under stirring for 1-2h, and then stop the reaction;

[0114] 3) Using SE series screw extrusion granulator, the reactant wet material obtained in 2) is transported to the screw extrusion granulator at a temperature of 5-10°C higher than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com