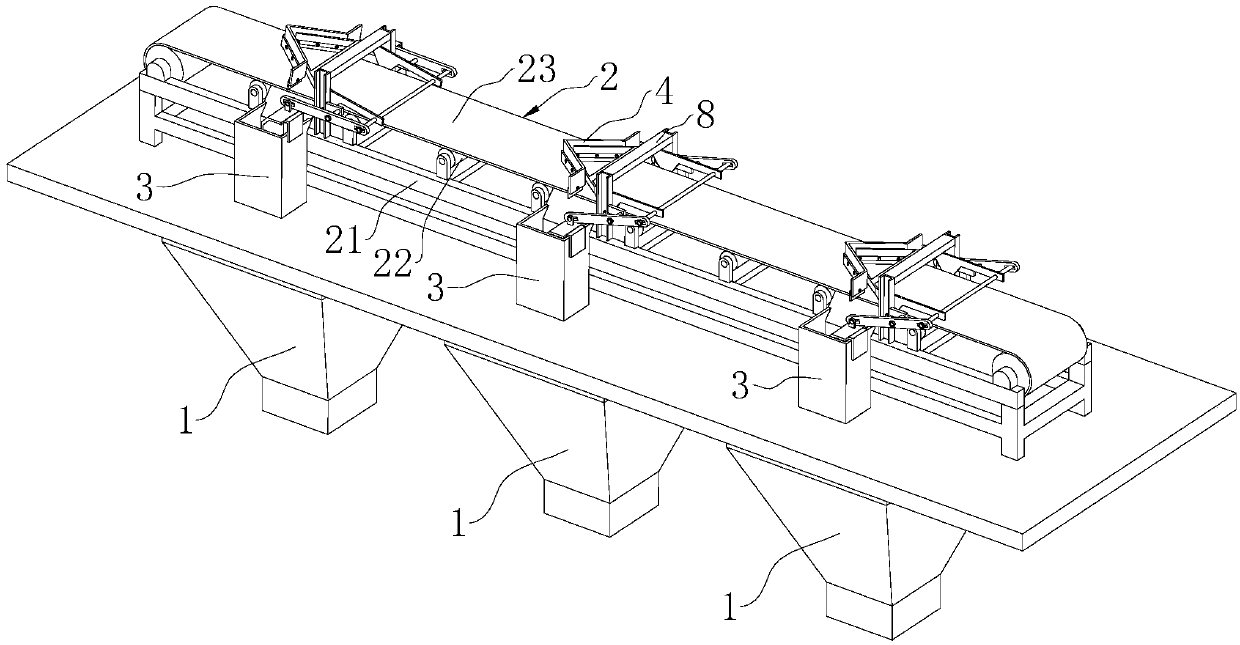

Fire coal conveying device

A conveying device and coal-fired technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of large space occupation, waste of energy consumption, high production costs, etc., to reduce floor space, reduce energy consumption, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

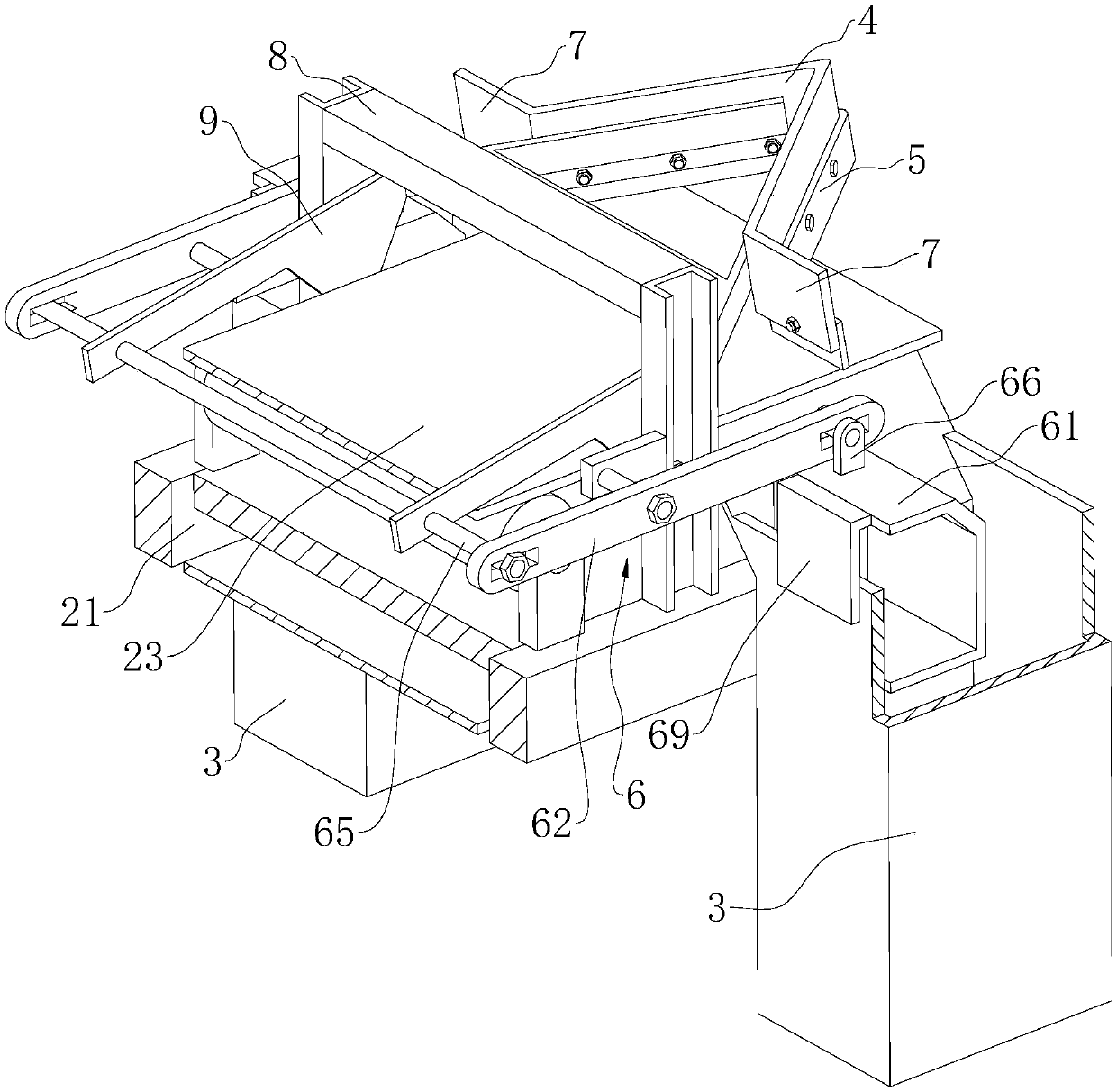

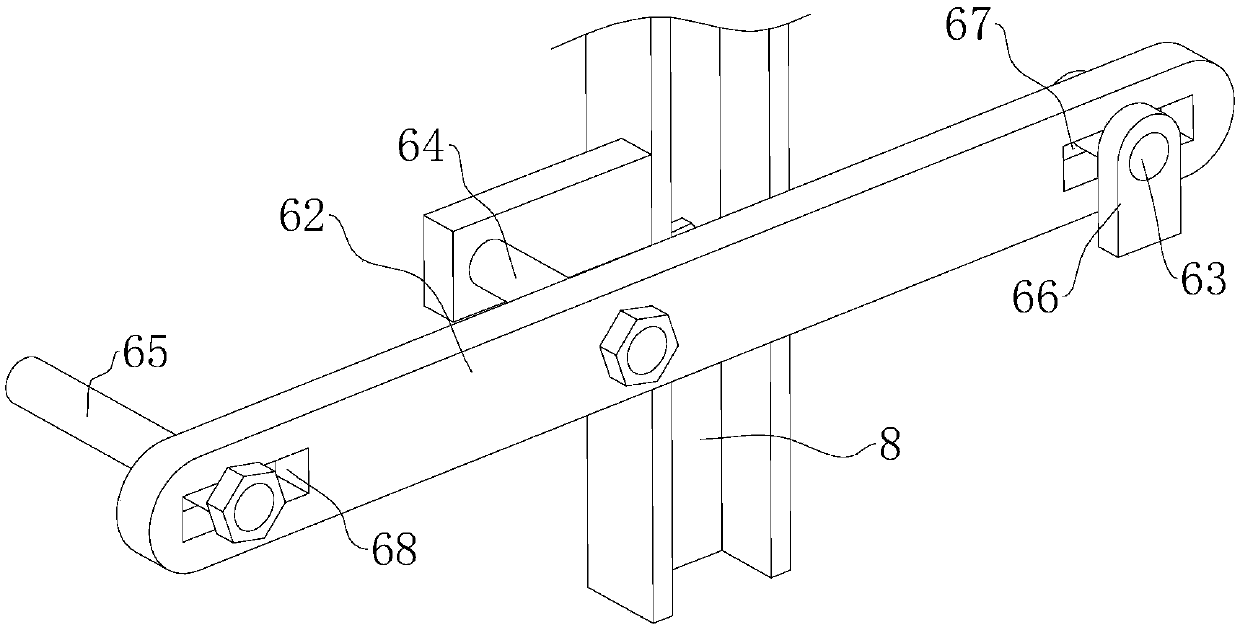

[0037] Embodiment 2: refer to Figure 4 The difference from Embodiment 1 is that the driving member 6 includes a hollow counterweight frame 61, a connecting rod 62 and a rotating shaft 611, the counterweight frame 61 is arranged in the coal storage bin 1, and the connecting rod 62 passes through the floor and the The upper end of the counterweight frame 61 is vertically fixed, and the rotating shaft 611 is fixed parallel to the width direction of the frame 21 above the end of the baffle plate 4 at the sharp corner; the upper end of the connecting rod 62 is provided with an arc-shaped groove 610 for the rotating shaft 611 to be plugged in and displaced. ; In this embodiment, the connecting rod 62 can only move vertically up and down under the limit effect of the floor; When there is less coal in the coal storage bin 1, the counterweight frame 61 hangs down freely, and under the gravity of the counterweight frame 61, the rubber pad 5 is driven to contact the conveyor belt 23; wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com