Wind power blade manufacturing method

A manufacturing method and technology for wind power blades, which can be applied to other household appliances, household appliances, household components, etc., can solve the problem of perfusion effect. It can reduce the probability of layup folds, reduce perfusion defects, and improve the utilization rate of molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

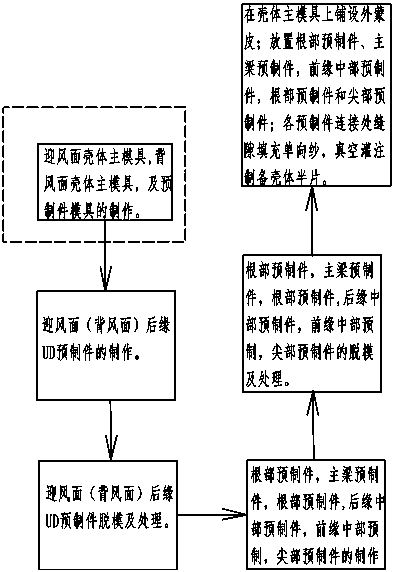

[0025] Specific implementation modes (embodiments) of the present invention will be described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention.

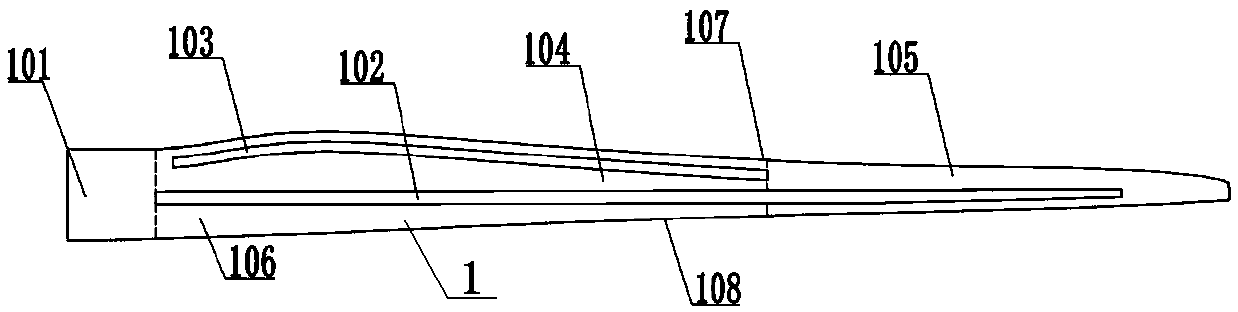

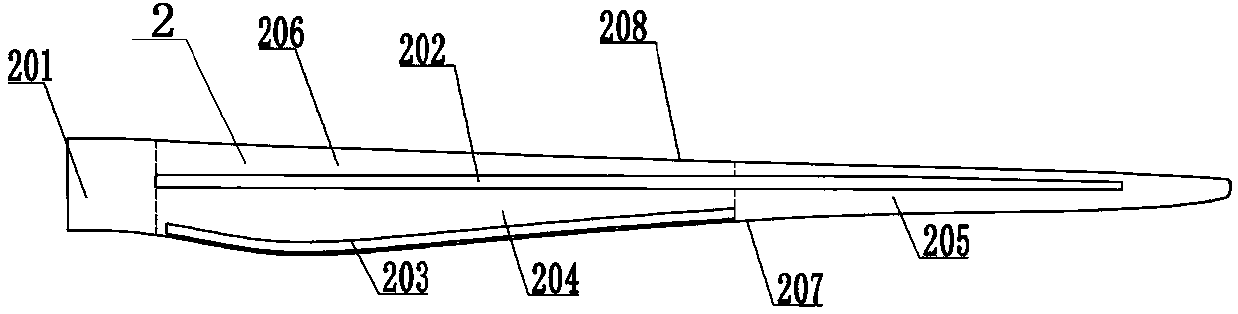

[0026] As shown in the figure: a method for manufacturing wind power blades, the shell 1 on the leeward side is divided into six regions according to the positions of the main girder on the leeward side and the rear edge UD on the leeward side: the root region 101 on the leeward side, The main beam area 102 on the leeward side, the UD area 103 on the rear edge of the leeward side, the middle area 104 on the rear edge of the leeward side, the tip area 105 on the leeward side, and the middle area 106 on the front edge of the leeward side; The position of the rear edge UD divides the shell 2 of the windward side into six areas: the root area 201 of the windward side, the main beam area 202 of the windward side, the UD area 203 of the rear edge of the windwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com