Full-automatic stone-like brick making machine and brick making method

A stone brick machine, fully automatic technology, applied in the direction of manufacturing tools, ceramic molding machines, supply devices, etc., can solve the problems of high process and material requirements, insufficient surface density, small molding area, etc., to reduce production cycle and beautiful appearance , the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

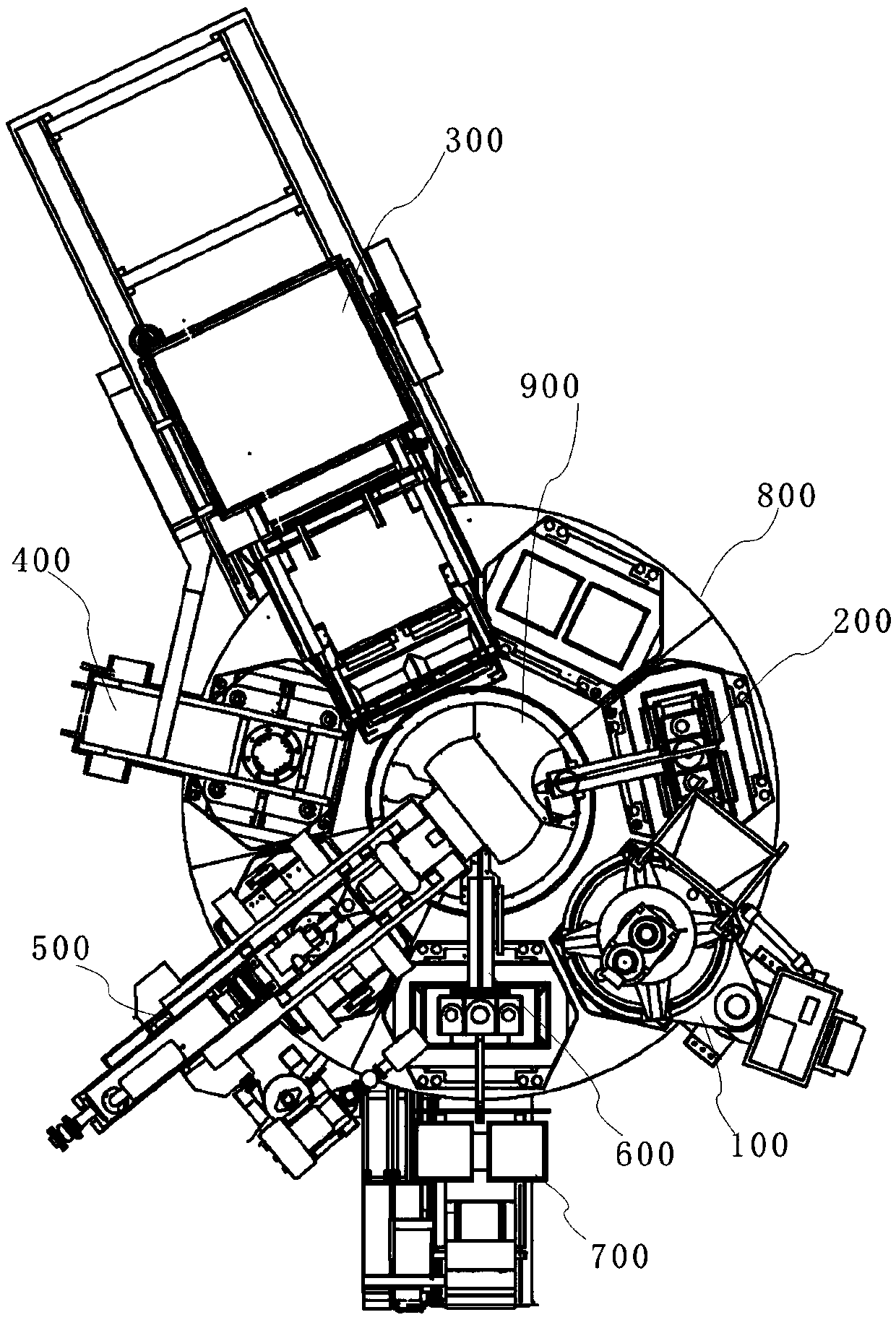

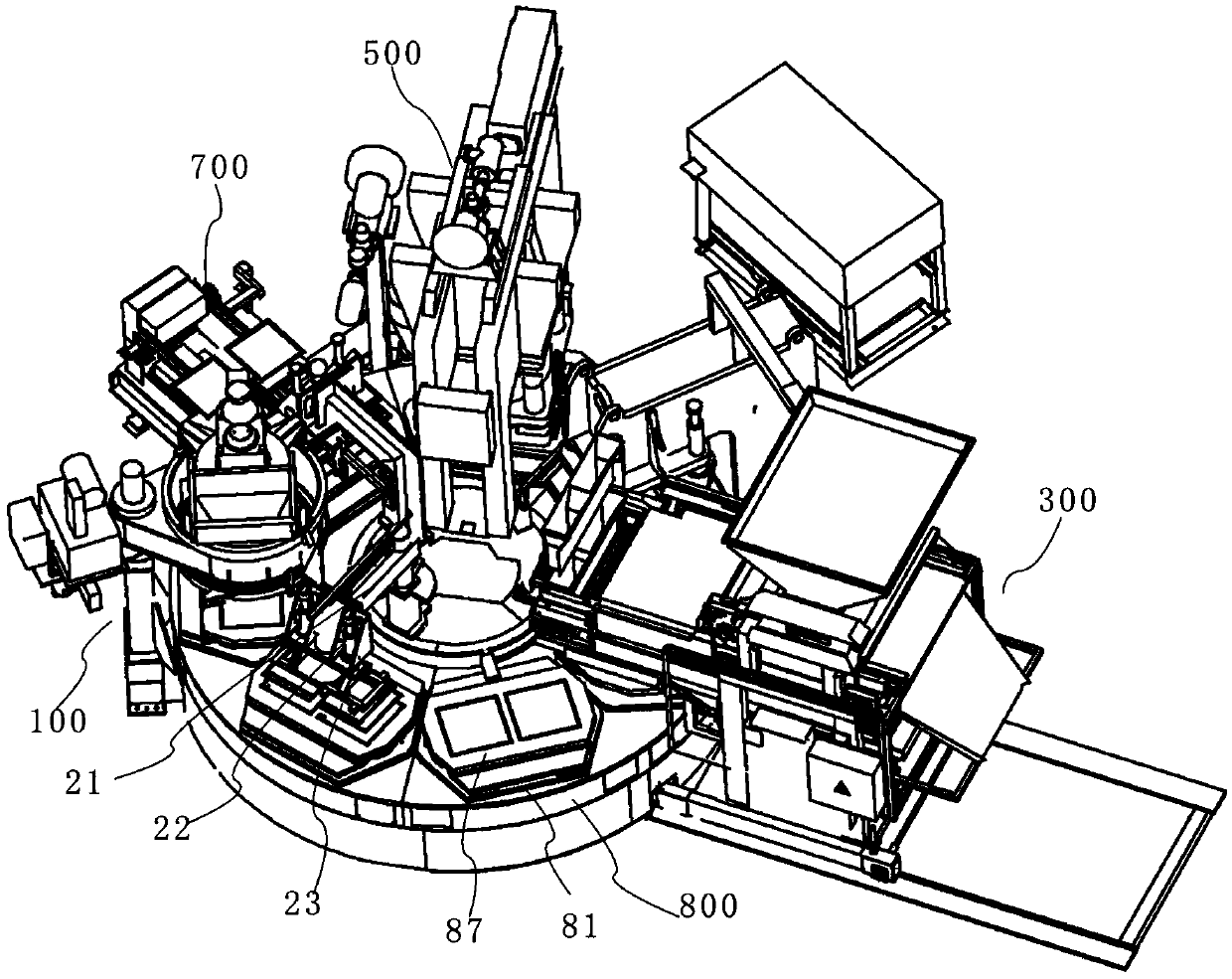

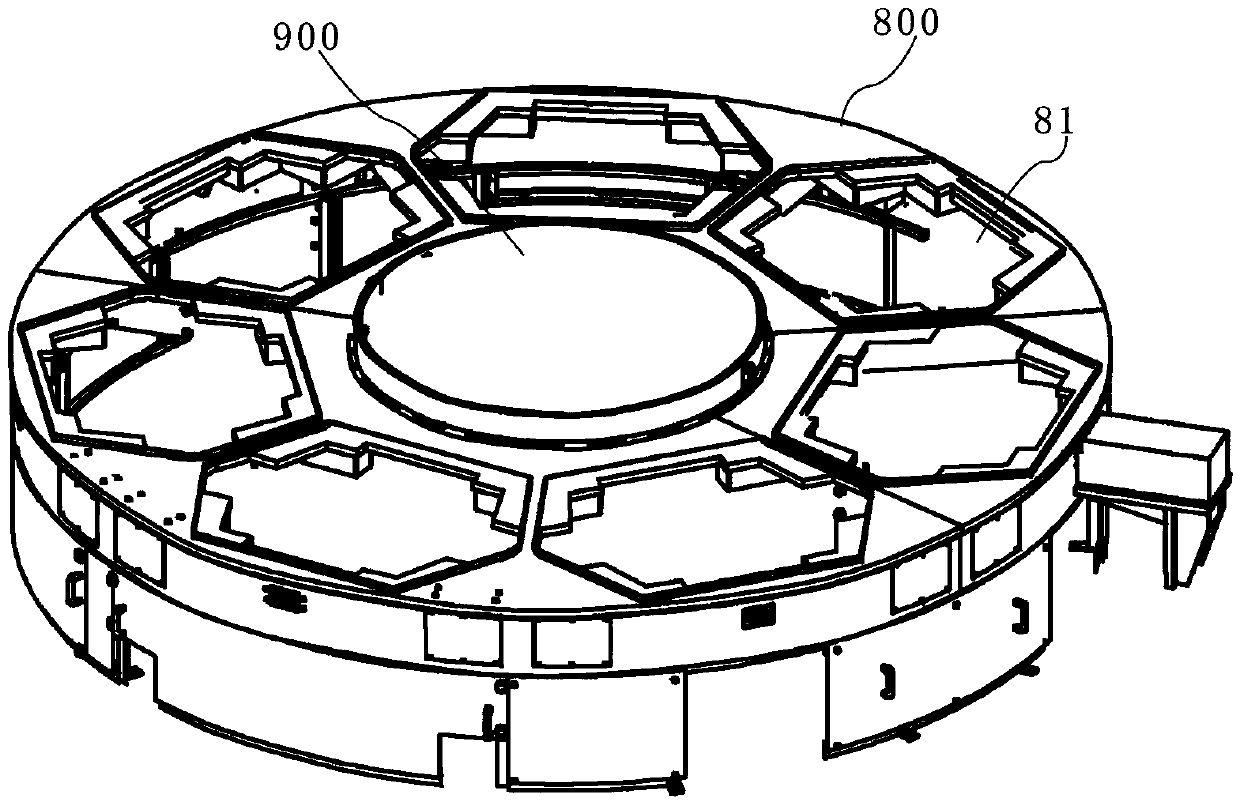

[0058] Such as Figure 1-5 As shown, the present embodiment provides a fully automatic imitation stone brick machine, including a center base 900 and a rotary disk 800 concentrically arranged outside the center base 900. The rotary disk 800 has seven mold positions 81 uniformly distributed on the circumference, each mold A vibration box 83 is fixedly installed at the position 81 respectively through a rubber pad 82, a vibration motor 84 is installed at the bottom of the vibration box 83 and the lowest end of the vibration motor 84 is above the lowest end of the vibration box 83, and the vibration box 83 Lifting oil cylinders 85 are respectively installed on both symmetrical sides, and the piston rod ends of each lifting oil cylinders 85 are respectively connected with connection blocks 86. When making bricks, respectively place mold frames 87 on each mold position 81 and make the mold frame 87 bottoms and Connection blocks 86 are connected. The vibration box 83 of the present...

Embodiment 2

[0093] This embodiment provides a fully automatic imitation stone brick machine. The difference between this embodiment 2 and the above embodiment 1 is that the aggregate distributing machine is canceled, and there are 2 A transition position, the main press unit 500 also includes a vacuum pump 59, and the vacuum pump 59 is installed on one side of the main press frame 51, such as Figure 26 shown. Alternatively, in Embodiment 2, only 6 mold positions may be provided, the aggregate distributing machine is canceled, a transition position is left between the vibrating press machine 200 and the pre-pressing machine 400, and the main press unit 500 also A vacuum pump 59 is included, and the vacuum pump 59 is installed on one side of the main press frame 51 .

[0094] The brick-making method of the full-automatic imitation stone brick machine of the present embodiment, concrete steps comprise as follows:

[0095] 1) At the fabric distributing position, add the stirred fabric into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com