A Planar Ultrasonic Vibration Assisted Machining Platform

A technology of ultrasonic vibration and auxiliary processing, applied in the direction of fluid using vibration, can solve the problems of chip accumulation, slow marking speed, large normal force of processing, etc., and achieve high-precision frequency, controllable amplitude, and controllable frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

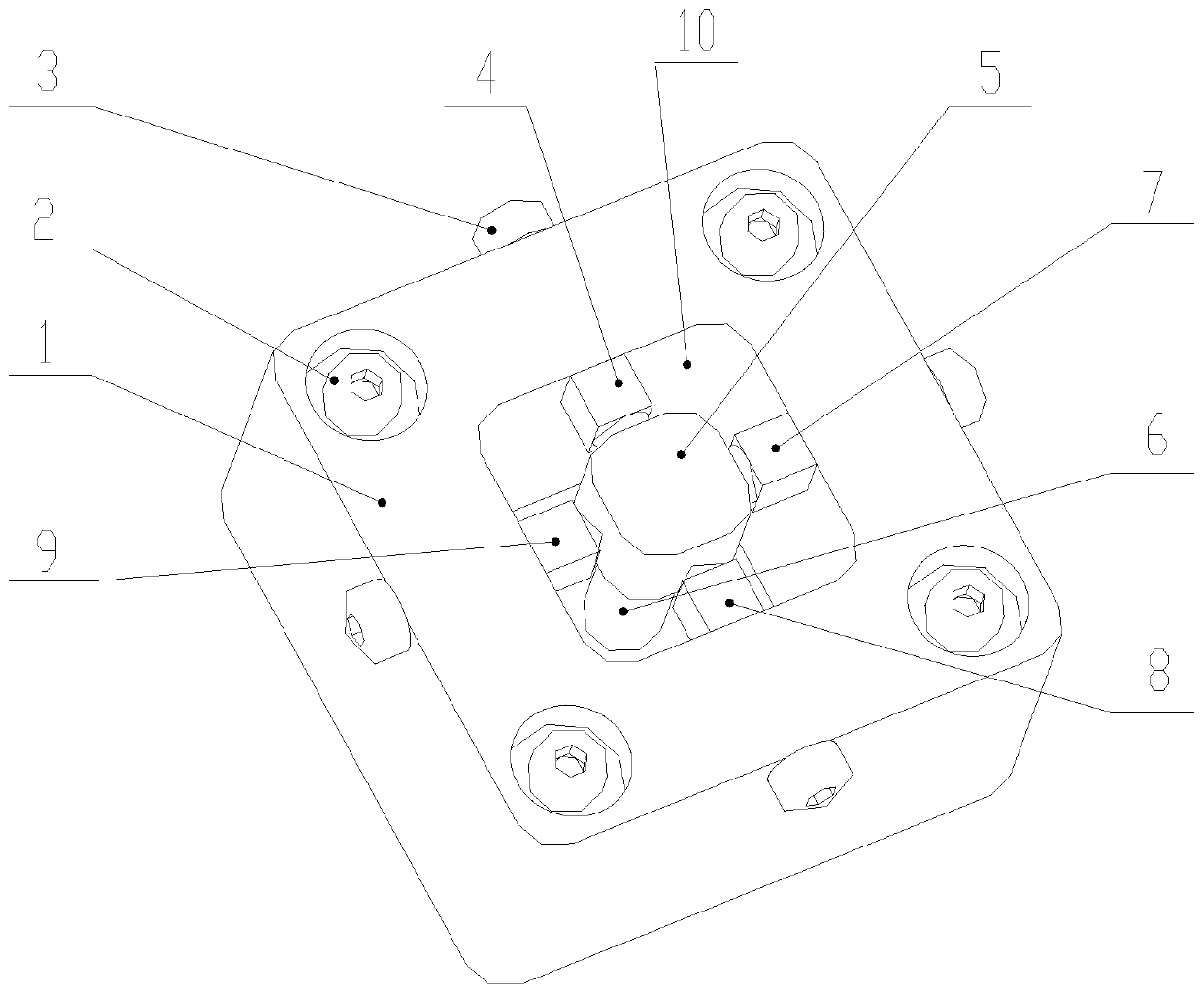

[0018] A planar ultrasonic vibration assisted processing platform of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

[0019] Such as figure 1 , figure 2 As shown, a plane ultrasonic vibration assisted processing platform of the present invention includes a rectangular base 1, a rectangular groove 10 is formed in the middle of the rectangular frame base 1, and the center of the rectangular groove 10 passes through a horizontally isotropic The decoupling pillar 6 made of material is provided with a moving platform 5 , the upper end of the decoupling pillar 6 is bonded to the moving platform 5 , and the lower end is fixedly connected to the inner bottom surface of the rectangular groove 10 . The transversely isotropic material is graphite or sedimentary rock, which decouples plane vibrations and eliminates coupling errors of ultrasonic vibrations in X / Y two working directions.

[0020] A piezoelectric ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com