Prefabricated transformer substation

A technology for pre-assembled substations and substation boxes, which is applied in power distribution substations, substation/switch layout details, electrical components, etc. technology, the effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

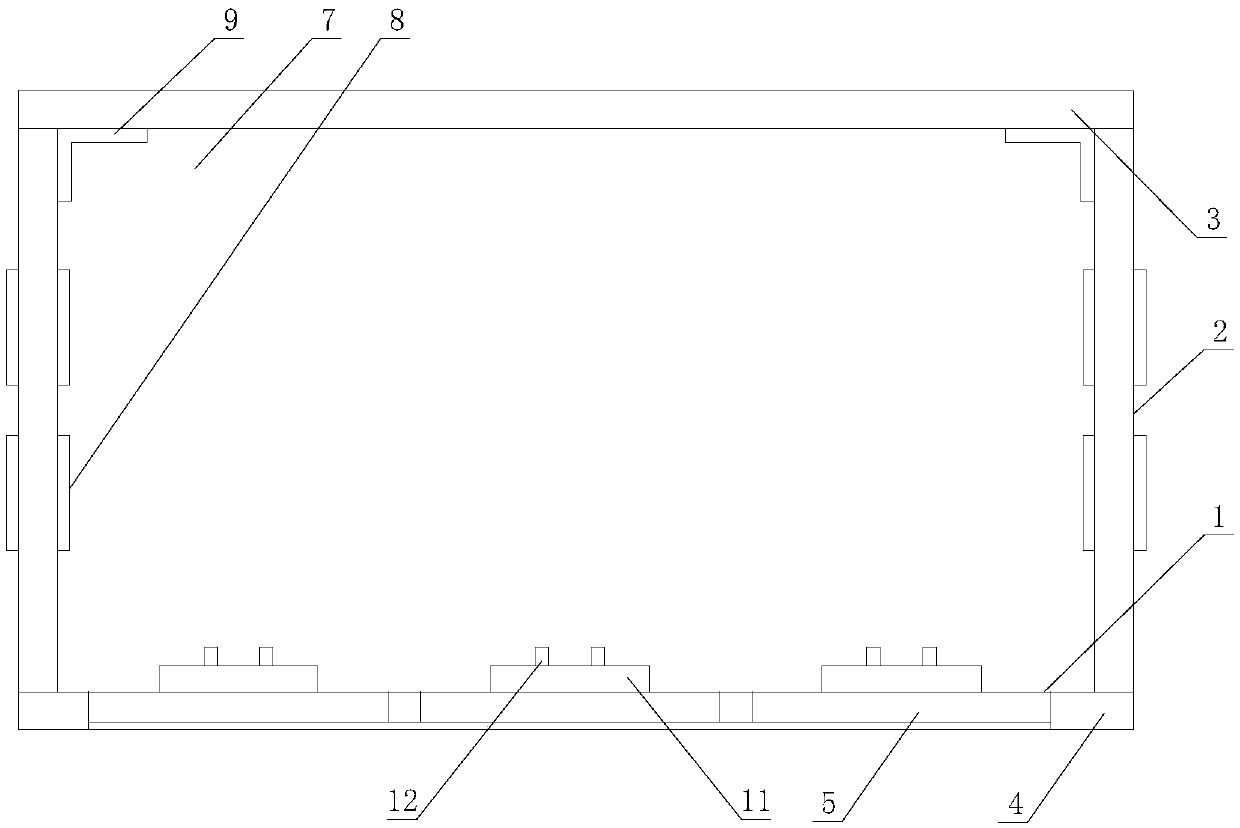

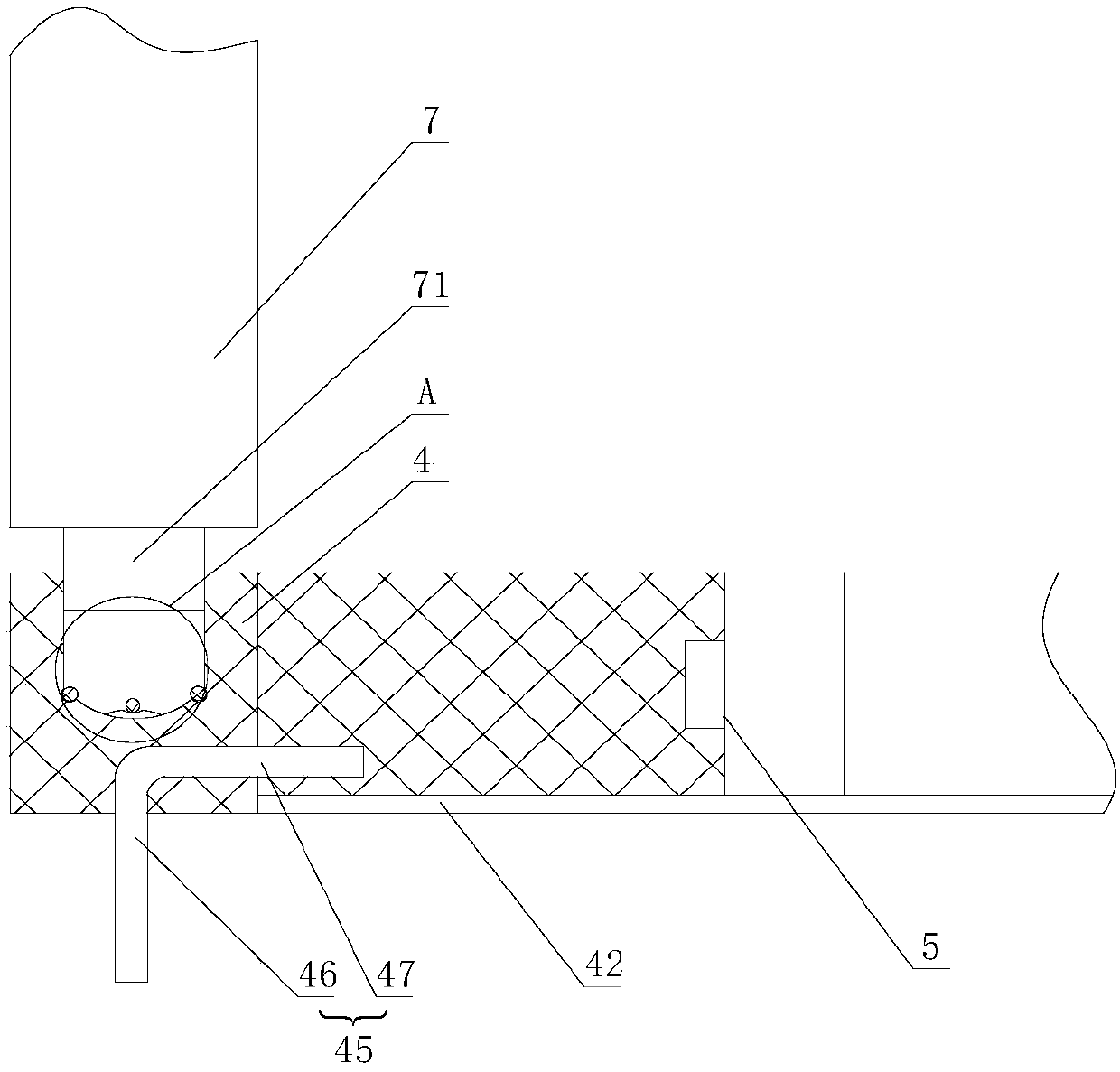

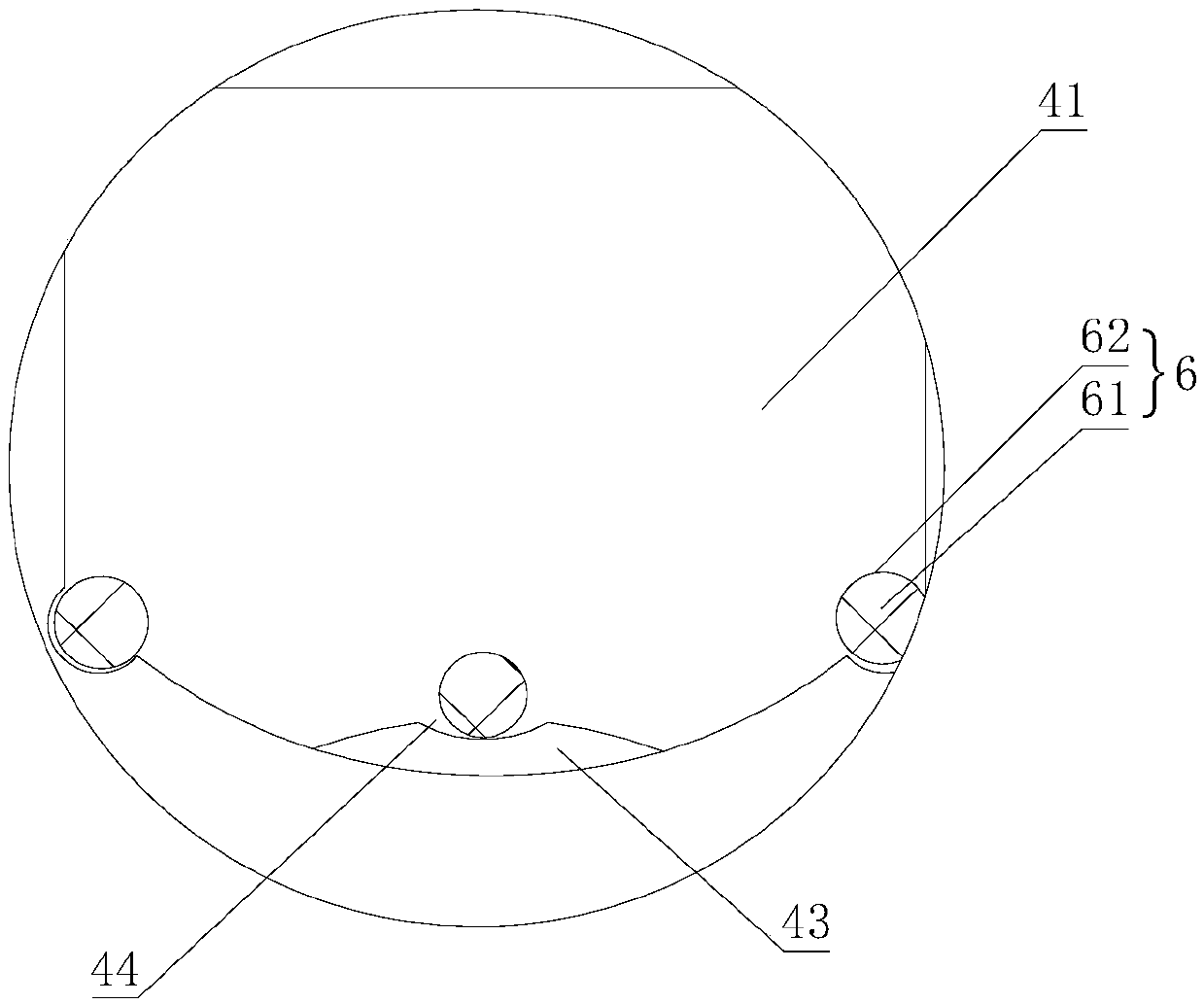

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a prefabricated substation includes a base 1, a casing 2 and a top cover 3, the base 1, the casing 2 and the top cover 3 enclose a substation box, and the base 1 includes a frame 4, a bottom plate 5 and adhesive A combined capsule 6, the adhesive capsule 6 includes an adhesive 61 and a packaging bag 62 coated outside the adhesive 61, the shell 2 includes a wallboard 7, a first connector 8 and a second connector 9, The wall panel 7 is connected to the shell 2 through a first connecting piece 8, the cover plate is mounted on the shell 2 through a second connecting piece 9, and the frame 4 includes a first mounting portion 41 and a second mounting portion 42 , the bottom plate 5 is installed on the frame 4 through the first installation part 41, the wall panel 7 is installed on the frame 4 through the second installation part 42, and the adhesive capsule 6 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com