LED (Light Emitting Diode) fluorescent powder deposition control device and method

A sedimentation control and phosphor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as product color area drift, and achieve the effect of ensuring product quality, reducing inventory pressure, and avoiding product color area drift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

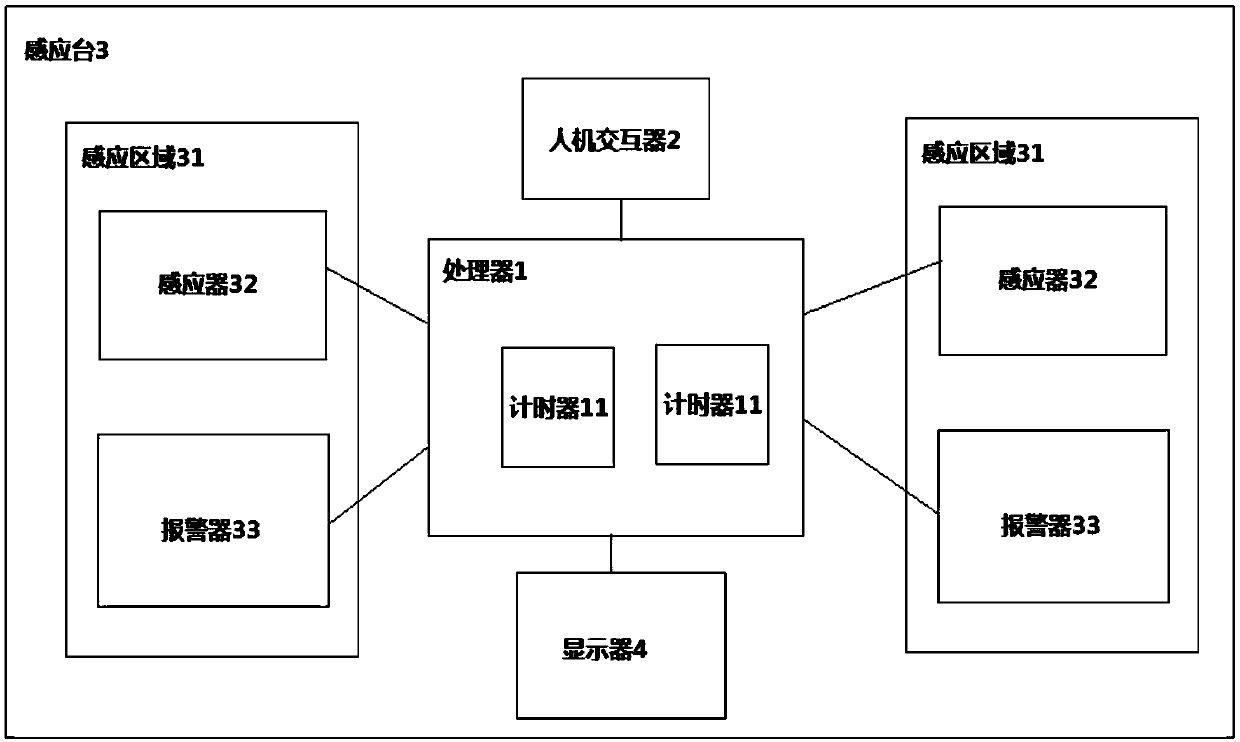

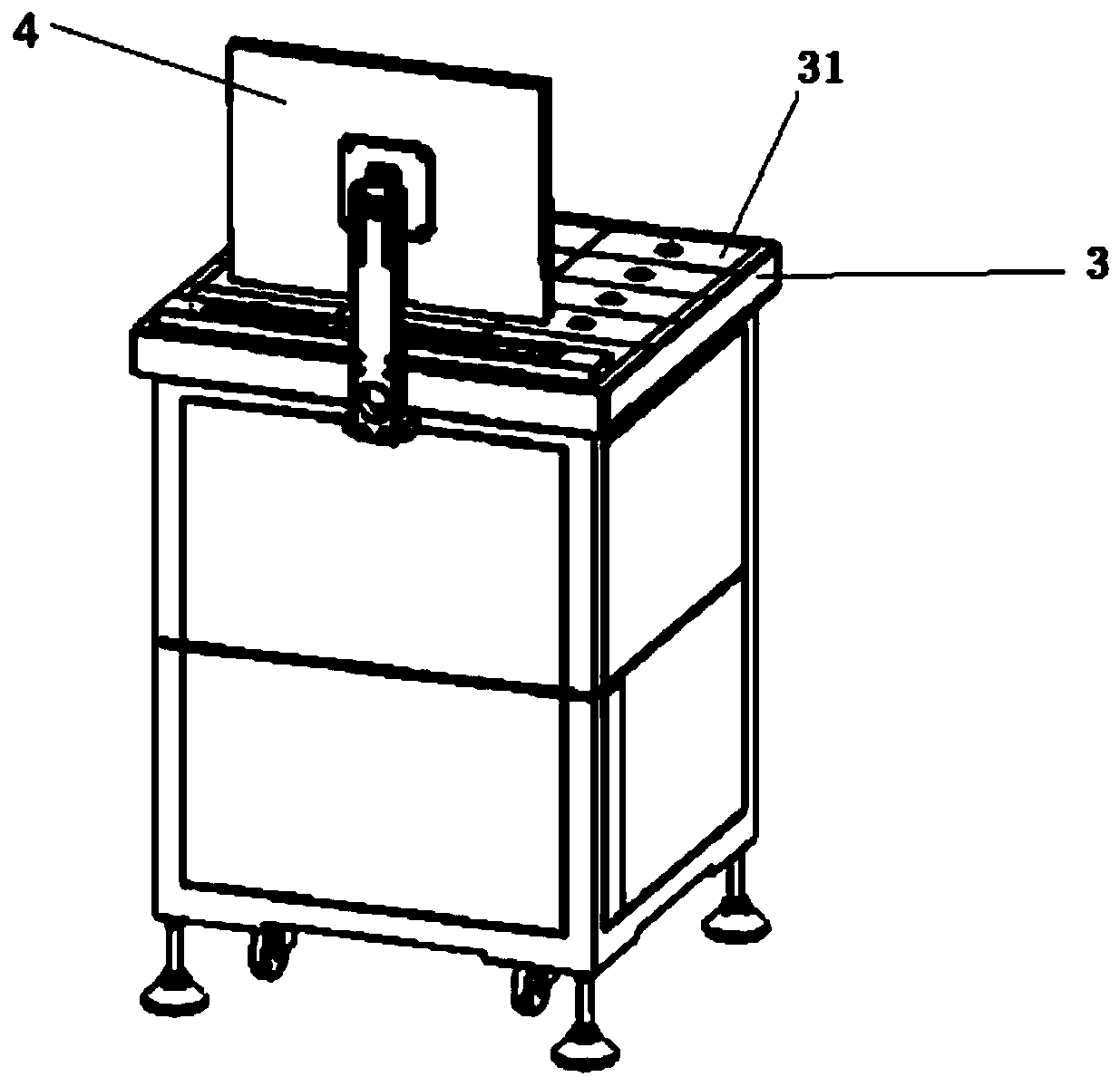

[0040] like figure 1 and figure 2 As shown, this embodiment 1 discloses a device for controlling LED phosphor sedimentation, including: a processor 1 with a plurality of timers 11, a human-computer interaction device 2 connected to the processor 1 and a device with a plurality of sensing areas 31 Induction station 3;

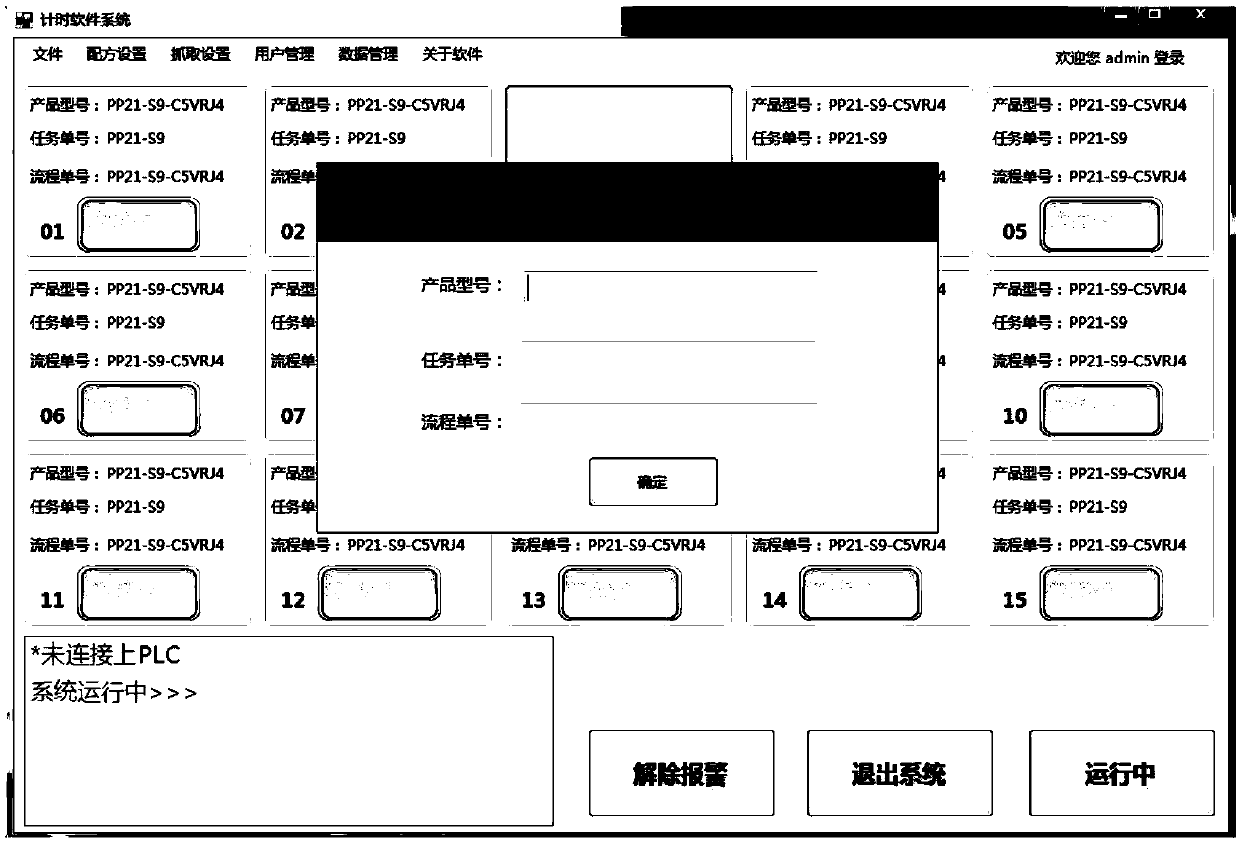

[0041] The human-computer interaction device 2 is used to receive the substrate information parameter input by the user, and send the substrate information parameter to the processor 1; the substrate information parameter includes the product information of the LED substrate, the settling time parameter and the sensing area parameter; the processor 1 is used to A timer 11 is bound to the sensing area parameter, and the settling time parameter is input into the bound timer 11;

[0042] Each sensing area 31 is provided with a sensor 32 and an alarm 33 connected to the processor 1, the sensor 32 is used to generate a sensing signal when sensing the LED substrate...

Embodiment 2

[0056] like Figure 5 As shown, this embodiment 2 corresponds to embodiment 1 and discloses a method for controlling the sedimentation of LED phosphor powder. Its technical effect is similar to that of embodiment 1, so it will not be repeated here. Specifically, the steps include:

[0057] S1. The human-computer interaction device receives the substrate information parameters input by the user, and sends the substrate information parameters to the processor; the substrate information parameters include LED substrate product information, settling time parameters and sensing area parameters;

[0058] S2. The processor includes a plurality of timers, and the processor binds a timer to the sensing area parameter, and inputs the settling time parameter into the bound timer;

[0059] S3. The sensor on a sensing area of the sensing table generates a sensing signal when sensing the LED substrate and sends it to the processor;

[0060] S4. When the processor receives the sensing sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com