Dyeing and strong lifting processing equipment for special strong yarns

A processing equipment and strong technology, applied in other manufacturing equipment/tools, manufacturing tools, liquid/gas/steam yarn/filament processing, etc., can solve uneven yarn stress, warp yarn breakage, uneven yarn impregnation, etc. Problems, to achieve the effect of helping to organize, reduce weight, and not easy to loosen and mess

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

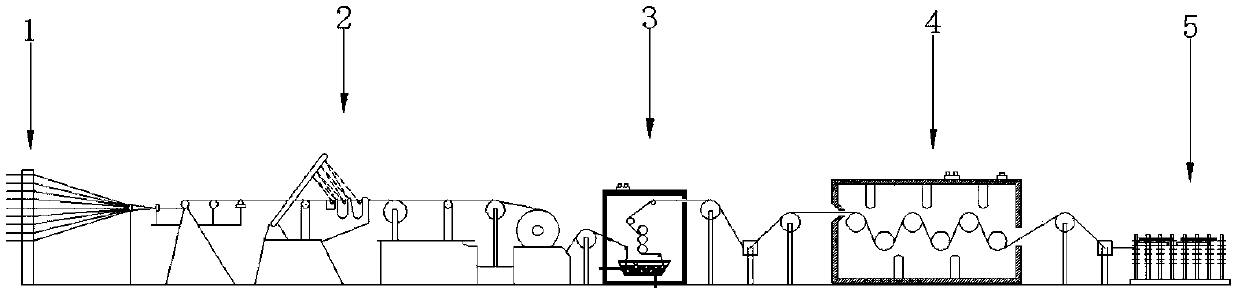

[0046] like figure 1 The dyeing and powerful lifting processing equipment for a special strong yarn shown is characterized in that it includes: a creel 1, a warping system 2, a pad dyeing system 3, a drying system 4 and an auxiliary creel 5; One side of the creel 1 is provided with a warping system 2; the side of the warping system 2 away from the creel 1 is provided with a pad dyeing system 3; the pad dyeing system 3 is provided on a side far away from the warping system 2 There is a drying system 4; the side of the drying system 4 away from the pad dyeing system 3 is provided with an auxiliary creel 5.

[0047] The working method of the dyeing and powerful lifting processing equipment of a special strong yarn described in this embodiment is: the yarn enters the warping system 2 through the creel 1 for warping, and the yarn padding and dyeing system 3 after warping Carry out pad dyeing, the yarn after pad dyeing is dried by drying system 4, and the yarn after drying is wound...

Embodiment 2

[0049] like figure 1 The dyeing and powerful lifting processing equipment of a special strong yarn shown includes: a creel 1, a warping system 2, a pad dyeing system 3, a drying system 4 and an auxiliary creel 5; the creel 1 One side is provided with a warping system 2; the side of the warping system 2 away from the creel 1 is provided with a pad dyeing system 3; the side of the pad dyeing system 3 away from the warping system 2 is provided with a drying system 4; The side of the drying system 4 away from the pad dyeing system 3 is provided with an auxiliary creel 5 .

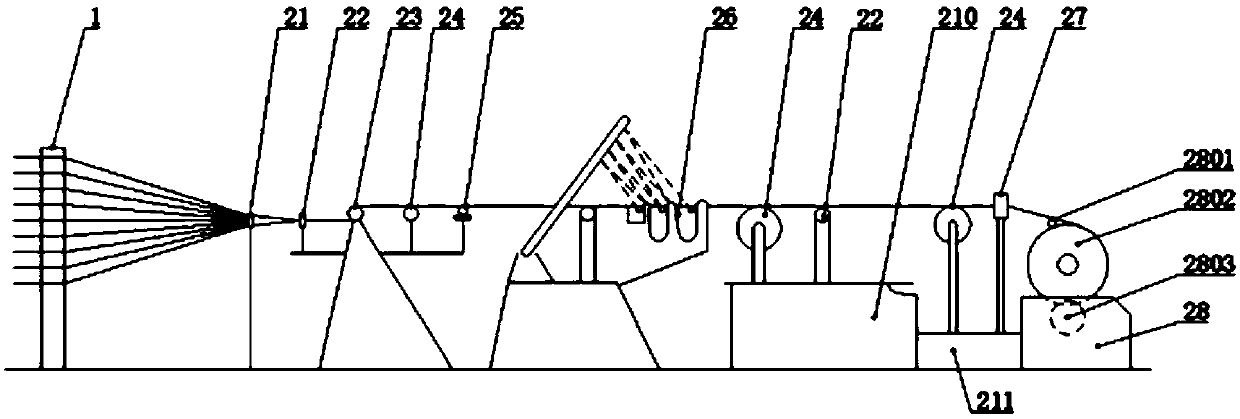

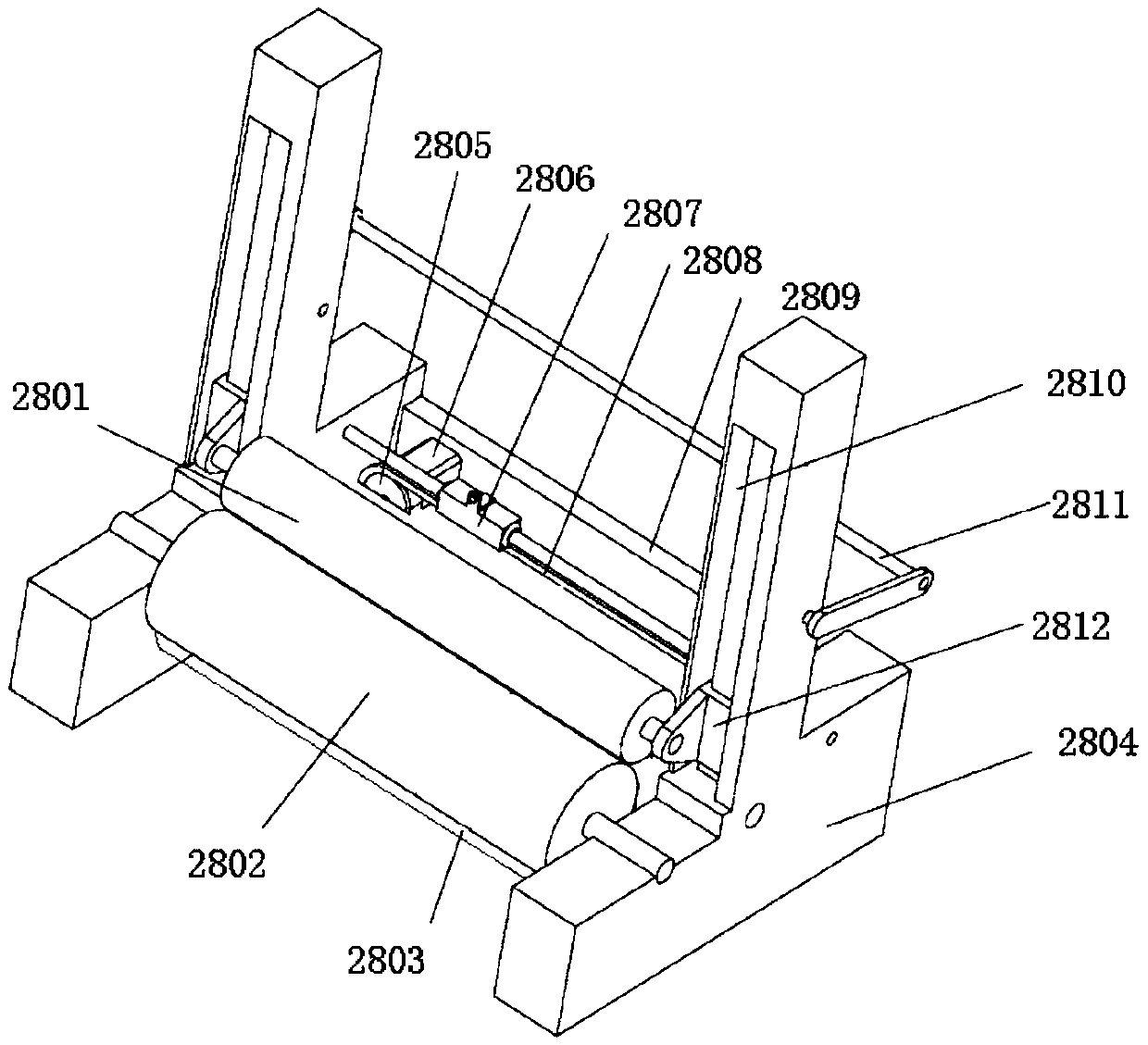

[0050] Otherwise, such as figure 2 As shown, the warping system 2 includes a yarn collecting plate 21, a tension roller 22, a yarn storage device 26, a telescopic reed 27, and a warping machine 28; the side of the yarn collecting plate 21 away from the creel 1 is provided with tension Roller 22, the side of the tension roller 22 away from the yarn collecting plate 21 is provided with a yarn storage device 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com