Equi-index plate arraying mechanism

A technology of equalizing trays and conveying mechanisms, applied in the directions of conveyor objects, transportation and packaging, packaging, etc., can solve the problems of reduced procedures, substandard product hygiene, etc., and achieves improved yield, convenient operation, and effective operation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

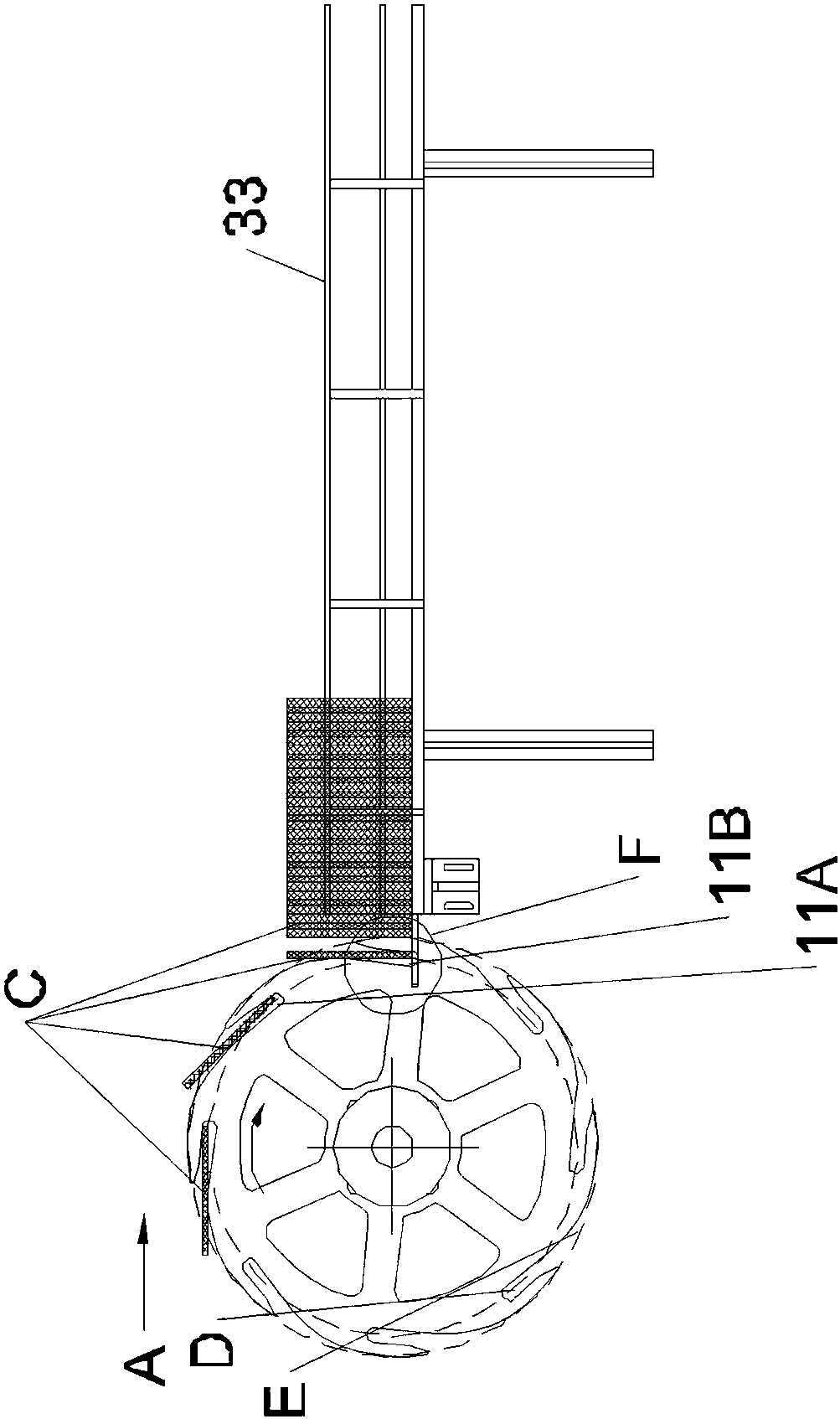

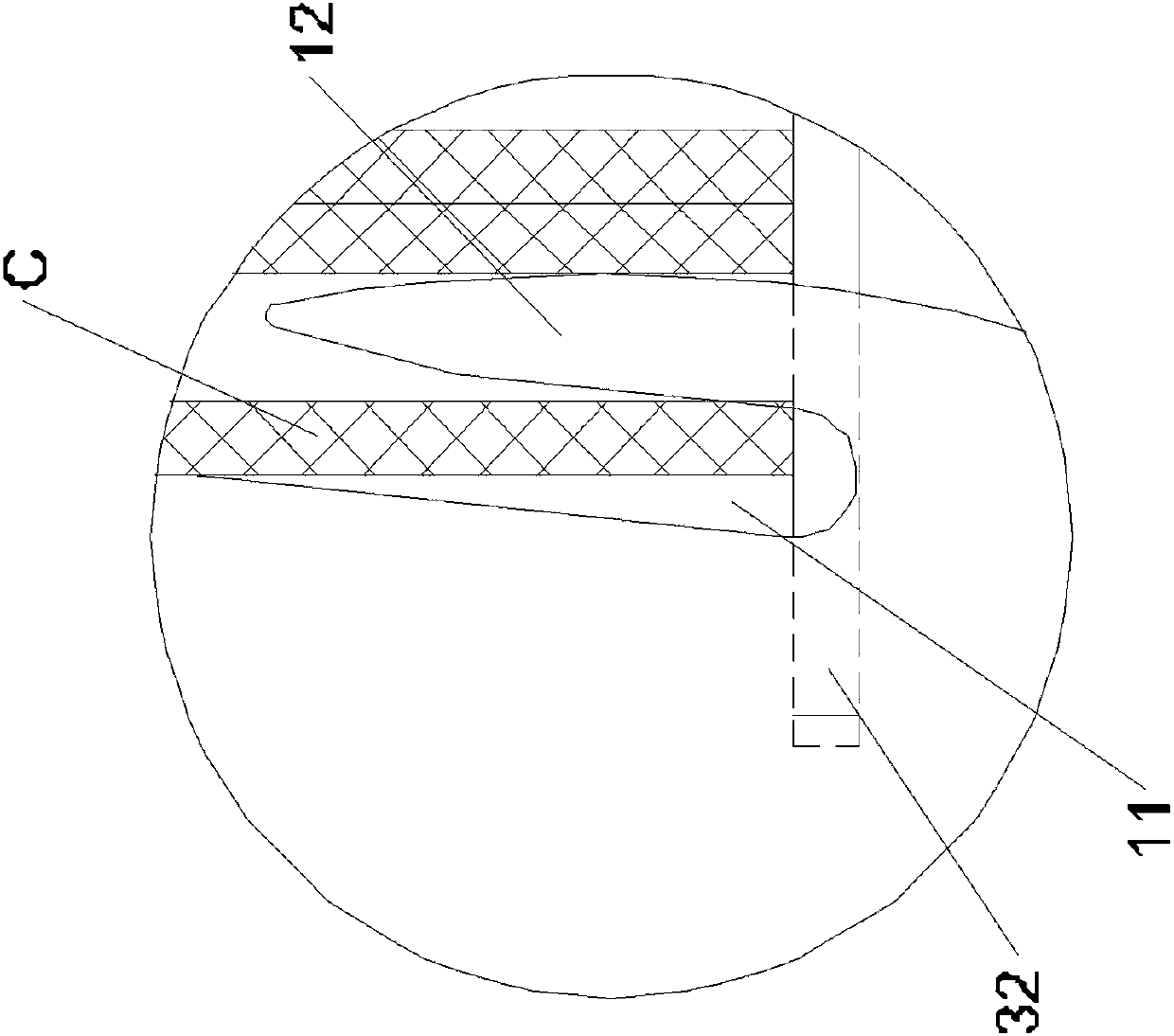

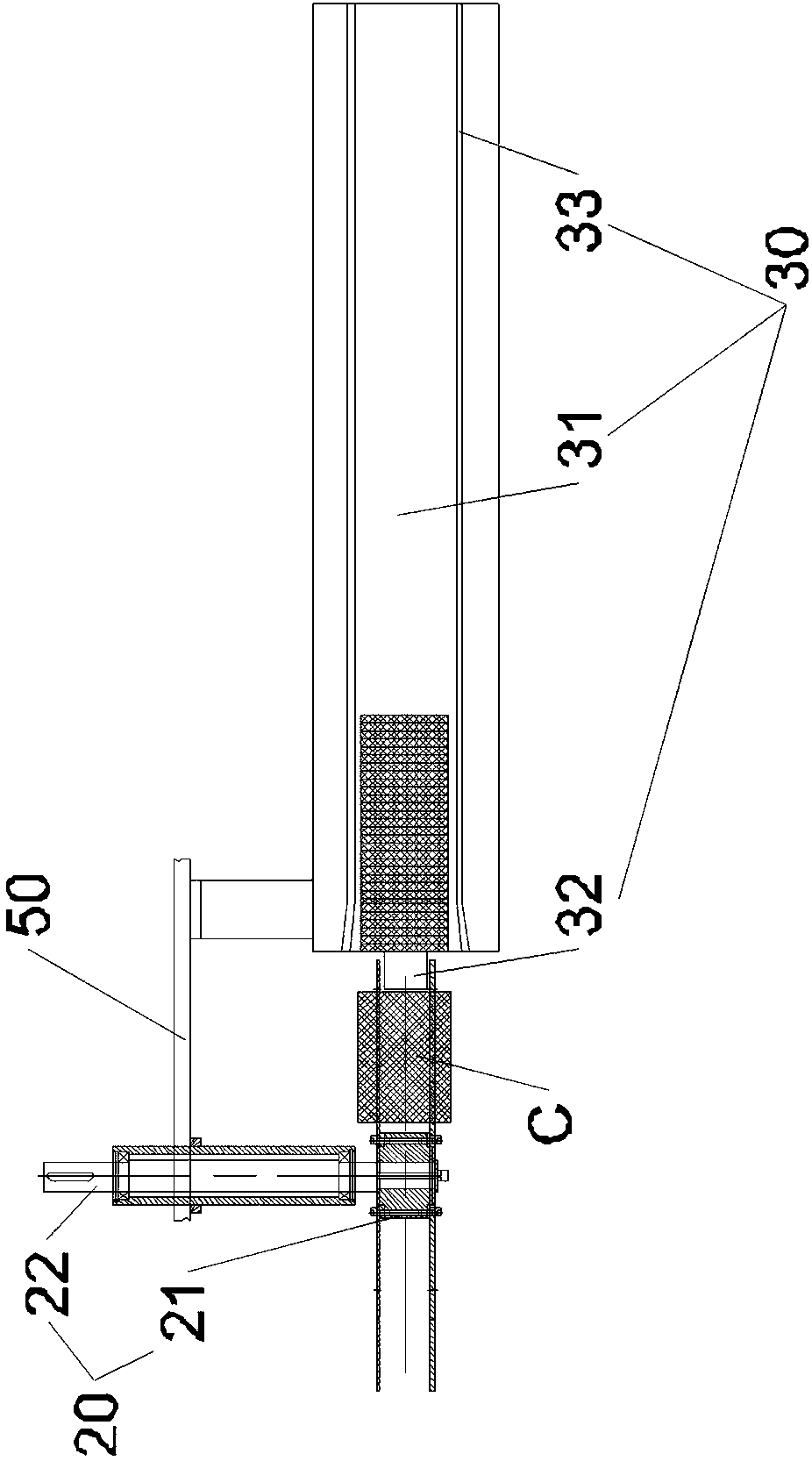

[0020] refer to Figure 1 to Figure 3 An arranging mechanism for aliquot trays includes an aliquot tray assembly 10 , an aliquot tray support assembly 20 and a product delivery mechanism 30 . In this embodiment, the product C rushes into the groove 11 of the aliquot tray assembly 10 from left to right in the horizontal direction A at high speed, and the aliquot tray assembly 10 rotates in a clockwise direction B to arrange the product C on the product delivery mechanism 30 On the discharge base plate 31.

[0021] Please combine Image 6 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com