Formation capacity grading method of lithium ion battery

A lithium-ion battery and capacity-division technology, applied in secondary batteries, electrochemical generators, non-aqueous electrolyte batteries, etc., can solve problems such as hindering lithium ion migration, shorten the formation process time, enhance liquid retention, and improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

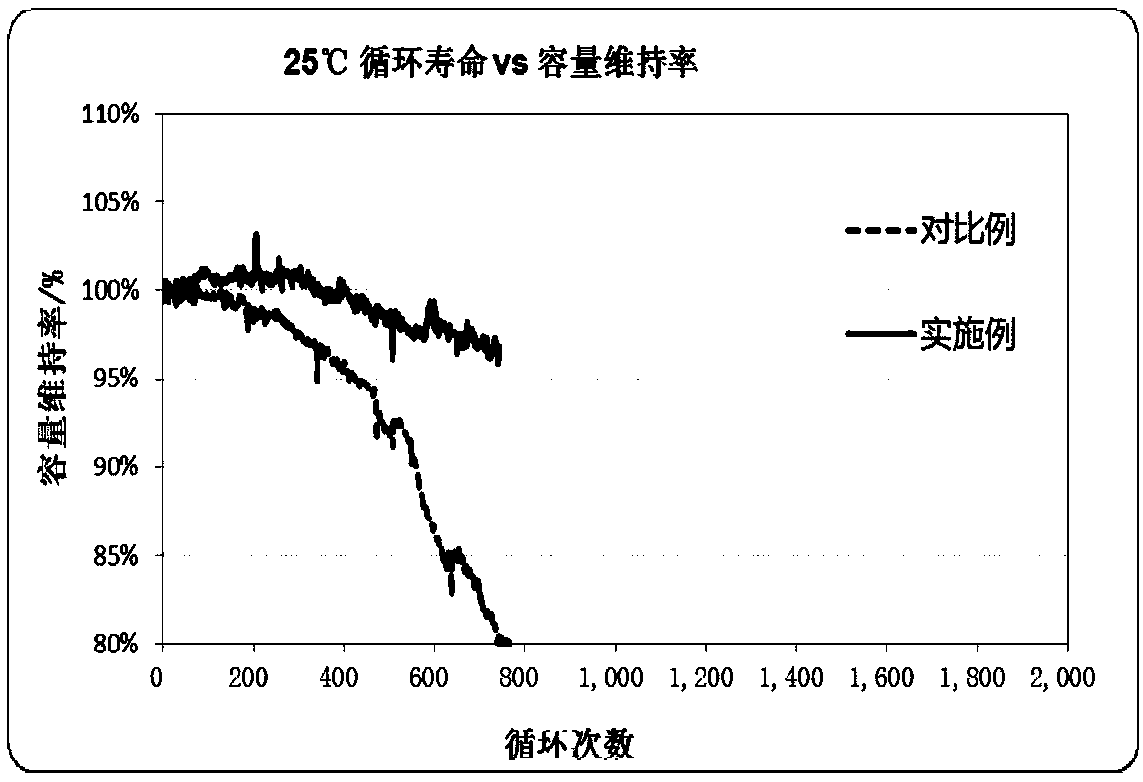

[0040] In this embodiment, a group of 10 batteries is formed according to the method of the present invention. The specific method is as follows.

[0041] Set the negative pressure to -70kpa, and empty the air inside the battery cell after the assembly of incoming materials, and the extraction time is 5 seconds. Inject liquid into the cell after pumping air through negative pressure (-70kpa), and the tolerance of liquid injection is required to be 0.1g. After the liquid injection is completed, the liquid injection port is sealed by a detachable corrosion-resistant sealing rubber nail to isolate the air.

[0042] Stand at room temperature before forming, the temperature is 23±3℃, and the time is 72±3h to ensure the infiltration of the electrolyte on the pole piece.

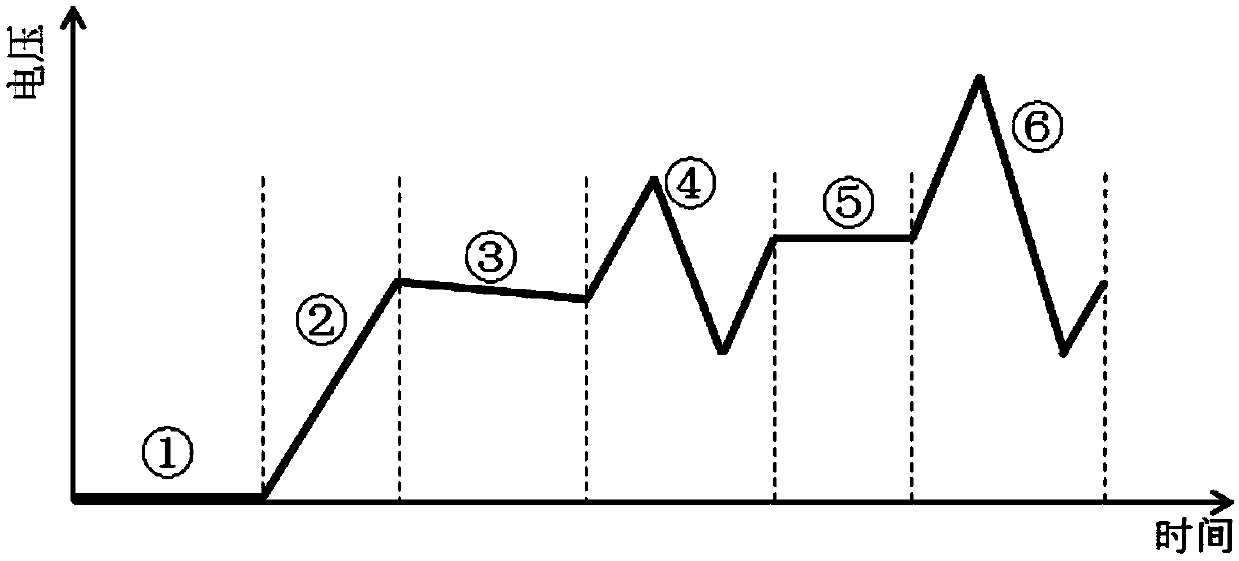

[0043] Preheat the battery at high temperature for 15 minutes to 60±3°C, open the seal, and charge at this temperature with a small current of 0.2C to a SOC state of 2%, and then switch to charge at 0.7C to a sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com