Carbon fiber support truss for secondary lens component of large-aperture telescope

A technology for supporting trusses and telescopes, applied to telescopes, optical components, installations, etc., can solve the problems of low rigidity of the support frame and easy deformation during processing, and achieve the effects of reducing quality, increasing specific stiffness, and increasing specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The inventive concept of the present invention is to use a discrete truss support structure instead of an integrated frame structure, and use carbon fiber composite materials with high specific stiffness instead of traditional metal materials, so as to greatly increase the rigidity of the support structure and reduce processing difficulty. The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

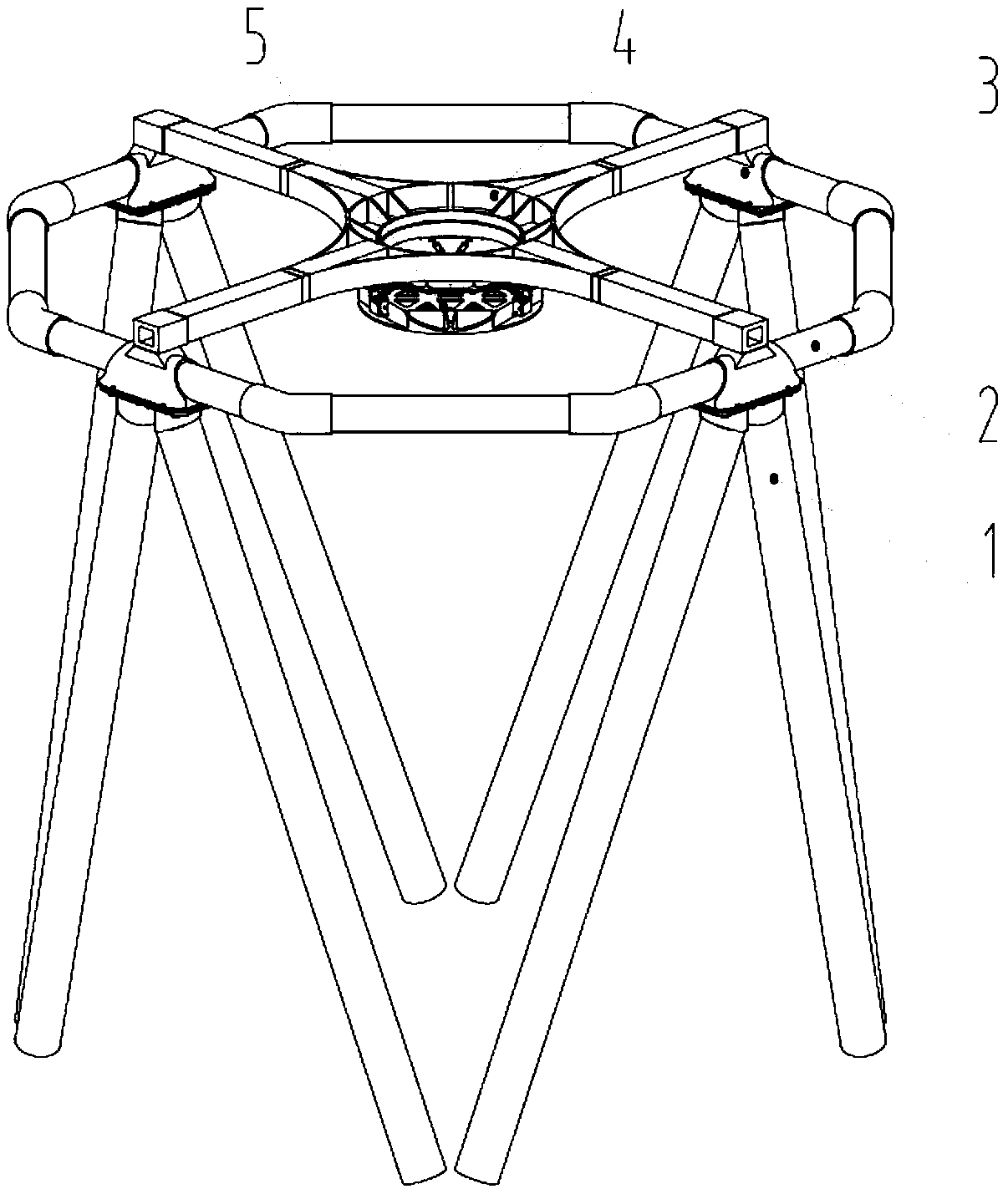

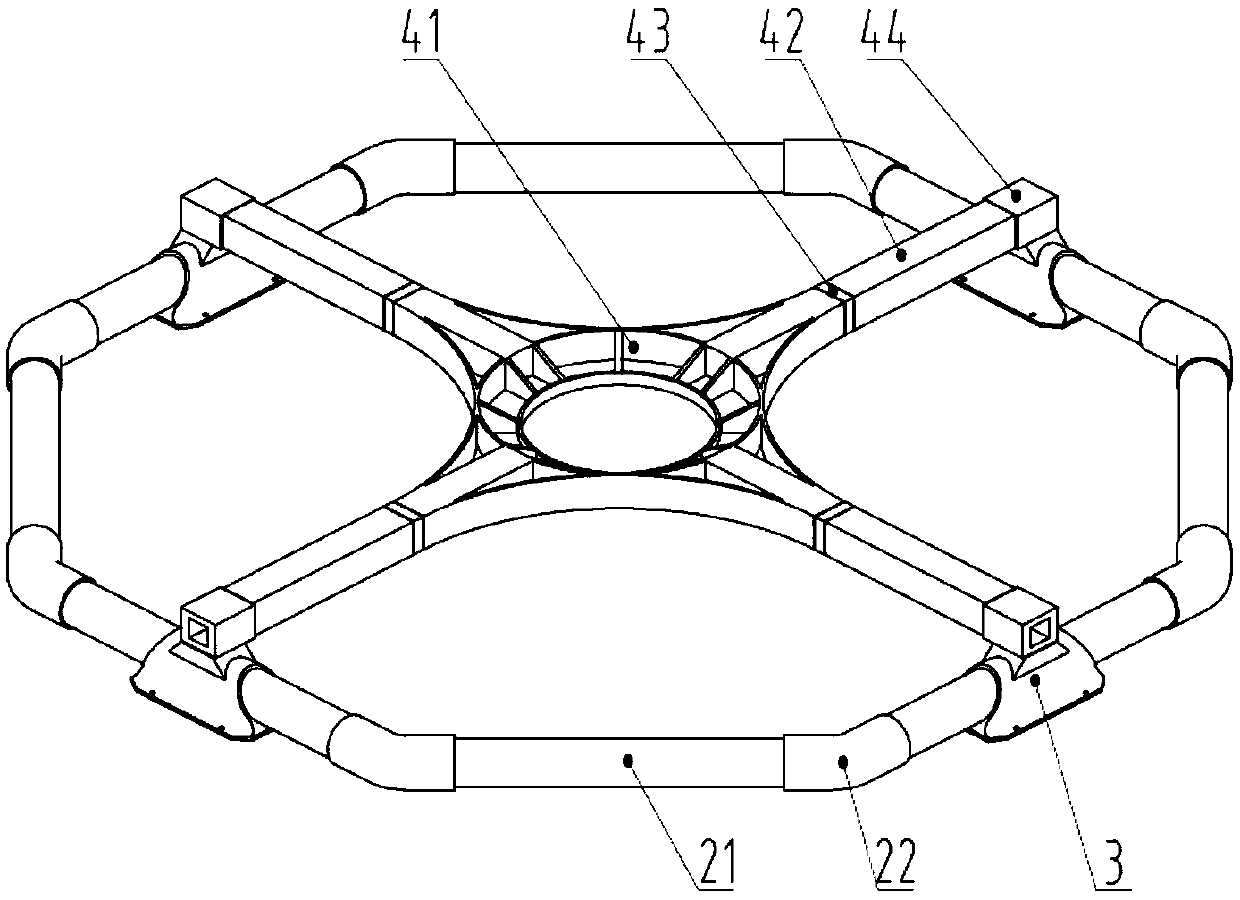

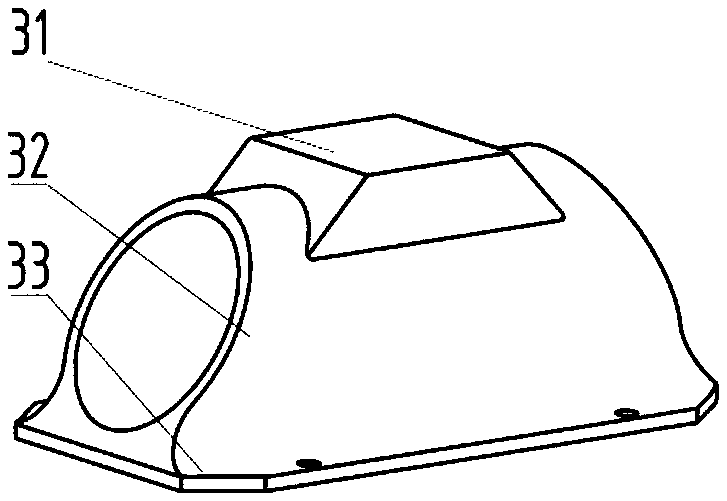

[0034] Such as figure 1 and figure 2 As shown, the carbon fiber supporting truss of the secondary mirror assembly of the large-aperture telescope in this embodiment includes an annular truss assembly 2 , a truss load-bearing assembly 4 and a fixed connection seat 3 . The ring truss assembly 2 includes eight groups of first truss rods 21 and eight connecting joints 22, and the eight groups of first truss rods 21 are connected end to end through eight connecting joints 22 to form a closed ring structure (that is, a regular oct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com