Method for measuring gas volume in battery, device and application thereof

A technology of internal gas and battery area, applied in measuring devices, volume measuring instruments/methods, measuring capacity, etc., which can solve the problems of undetectable initial internal gas, undetectable gas distribution, poor sensitivity to trace gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Measure the internal gas volume of the lithium iron phosphate-graphite soft-pack lithium-ion battery with a size of 70mm×80mm×3.2mm.

[0058] Make 10 lithium iron phosphate-graphite soft pack lithium-ion batteries of the same size and type. This type of battery normally requires 4.25mL of electrolyte to ensure sufficient infiltration. During the production process, the amount of electrolyte was deliberately controlled to be 4.25, 4.20, 4.15, 4.10, 4.05, 4.00, 3.95, 3.90, 3.85, 3.80mL, and the corresponding V j 0, 0.05, 0.10, 0.15, 0.20, 0.25, 0.30, 0.35, 0.40, 0.45 mL, respectively.

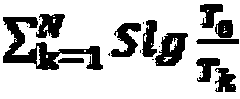

[0059] Divide each battery into 35×40 small square areas of 2mm×2mm along the largest surface, actually the cross section is 4mm 2 A small rectangular body of 35×40, a cross-sectional area of the small rectangular body A=4mm 2 .

[0060] The ultrasonic transducers are a pair of focused ultrasonic transducers with a frequency of 0.5MHz, a diameter of 1.0cm, and a focal length of 2cm. ...

Embodiment 2

[0067] Monitor the internal lithium analysis process of lithium iron phosphate-graphite soft-pack lithium-ion battery with a size of 70mm×80mm×3.2mm.

[0068] Make a normal battery of this type, charge and discharge at minus 20°C with a current of 6A, and at the same time conduct ultrasonic scanning with the method described in Example 1, and judge the internal gas volume and distribution of the battery. It can be found that there is no gas inside the battery in the initial state, and the ultrasonic transmission signal intensity in each area is uniform. After 3 cycles, the total amount of internal gas was measured to be 21 μL, and it was mainly distributed in the middle part of the two tabs of the battery. It is judged that this part of the gas is accompanied by the process of lithium analysis. After 10 cycles, the total amount of gas increased to 35 μL, indicating that the amount of lithium precipitated increased.

[0069] The present invention also provides a device for re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com