Tower crane foundation structure applicable to restricted space

A technology of tower crane foundation and confined space, which is applied in the direction of infrastructure engineering, construction, etc., can solve the problems of increasing construction cost, long construction period, increasing construction land, etc., to increase horizontal stiffness, reduce construction difficulty, and increase structural strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

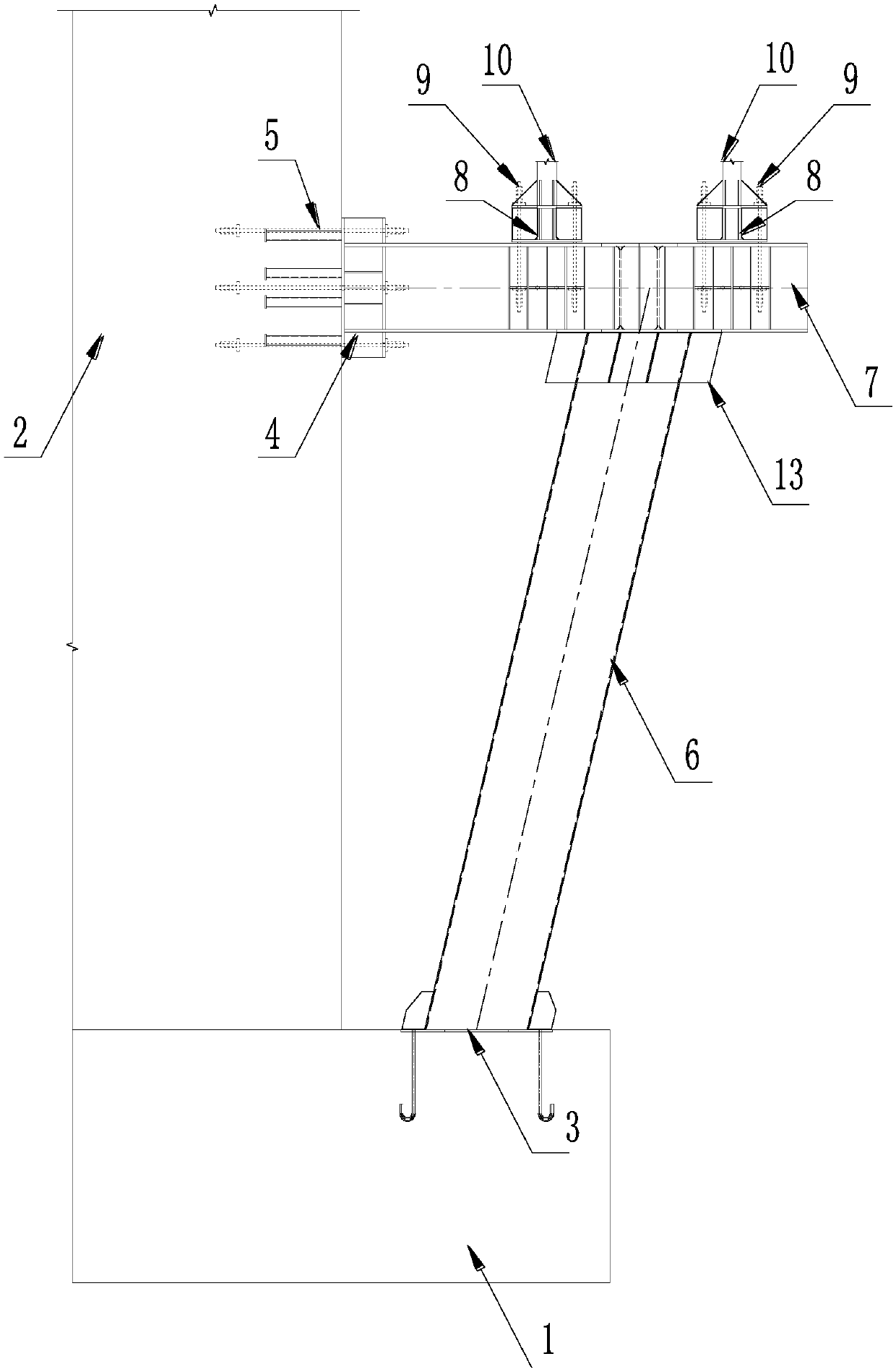

[0027] Embodiment 1: A tower crane foundation structure for confined spaces, see figure 1 As shown, including cap 1 and pier body 2 arranged on cap 1, cap 1 is provided with a plurality of cap embedment parts 3, and pier body 2 is provided with a plurality of pier body pre-embedded parts 4, so The base structure of the tower crane described above also includes a steel pipe column 6 and two steel beams 7, one end of the steel pipe column 6 is connected to the embedded part 3 of the cap, the other end of the steel pipe column 6 is connected to two steel beams 7, and the connection between the steel pipe column 6 and the steel beam 7 The minimum distance from the connection point to the pier body 2 is greater than the minimum distance from the connection point between the steel pipe column 6 and the embedded part 3 of the pier to the pier body 2, and the steel pipe column 6 is installed on the cap 1 by tilting outward relative to the pier body 2.

[0028] see figure 1 As shown, ...

Embodiment 2

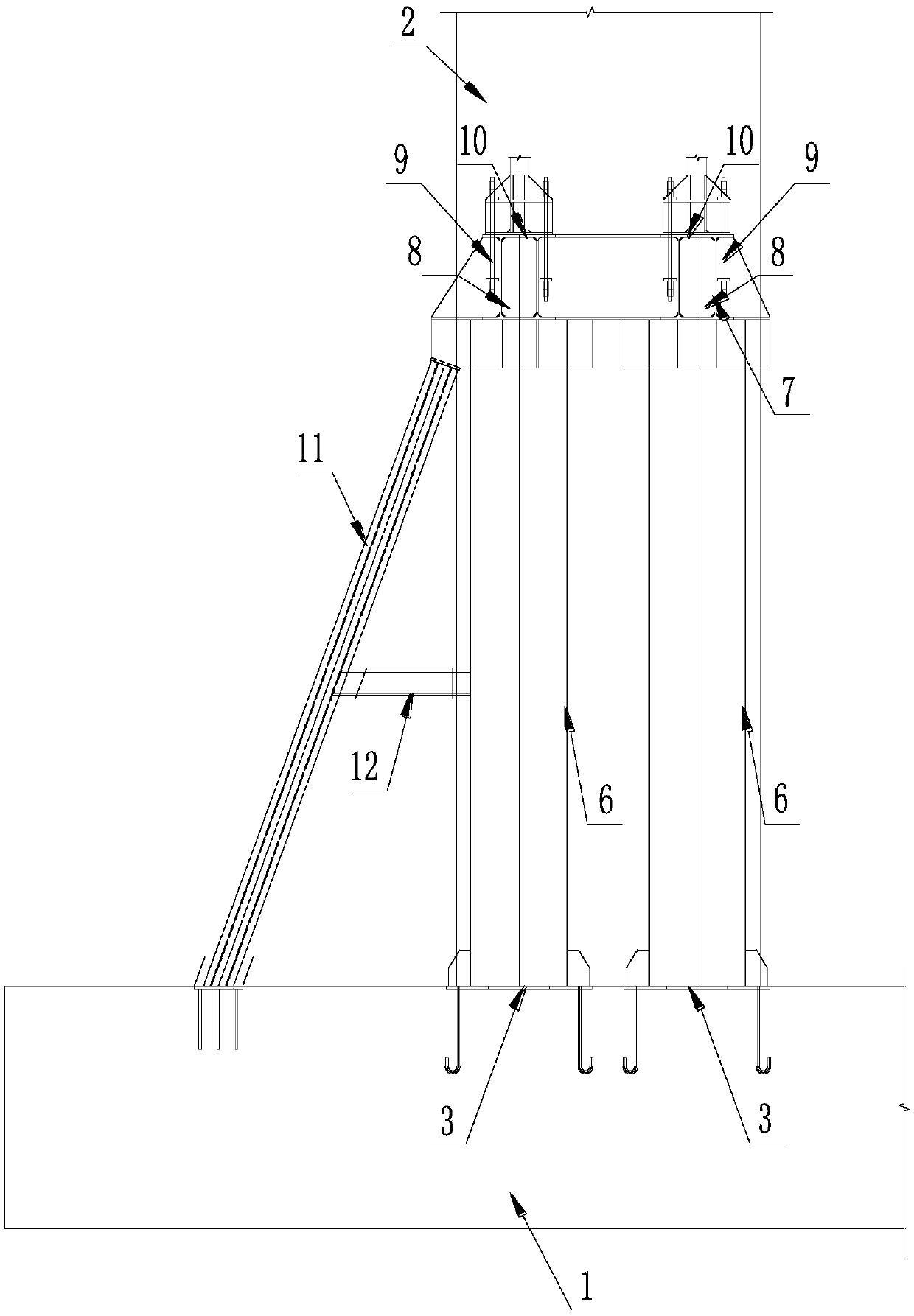

[0030] Embodiment 2: on the basis of embodiment 1, refer to figure 2 As shown, the steel pipe columns 6 are two substantially parallel steel pipe columns 6 , one steel pipe column 6 is connected to a steel beam 7 , and the other steel pipe column 6 is connected to another steel beam 7 .

[0031] In the embodiment of the present invention, two steel pipe columns 6 are used to provide support for the horizontal steel beam 7, which not only reduces the diameter of the steel pipe column 6, facilitates installation and speeds up construction, but also facilitates the lifting of the foundation structure of the tower crane. stability.

Embodiment 3

[0032] Embodiment 3: on the basis of embodiment 1, refer to figure 2 As shown, a plurality of steel distribution beams are arranged between the two steel beams 7 . Sectional steel is a kind of high-efficiency section with more optimized section area distribution and more reasonable strength-to-weight ratio. The two steel beams 7 are connected by section steel distribution beam, which is not only convenient for construction, less construction materials and light in structure weight, but also can be used in all directions. Both have strong bending resistance, improve the overall rigidity of the tower crane installation platform, and reduce external interference.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com