Integrated coal-water-slurry burner and ignition method

A technology of coal water slurry and cooling water, which is applied in the details of gasification device, granular/powdered fuel gasification, petroleum industry, etc. It can solve the problem of large axial velocity component of the mixture, affecting the residence time of the material, and the wear of the inner cavity of the nozzle, etc. problem, achieve the effect of increasing the residence time, avoiding unreasonable release of thermal stress, and stabilizing the ignition system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

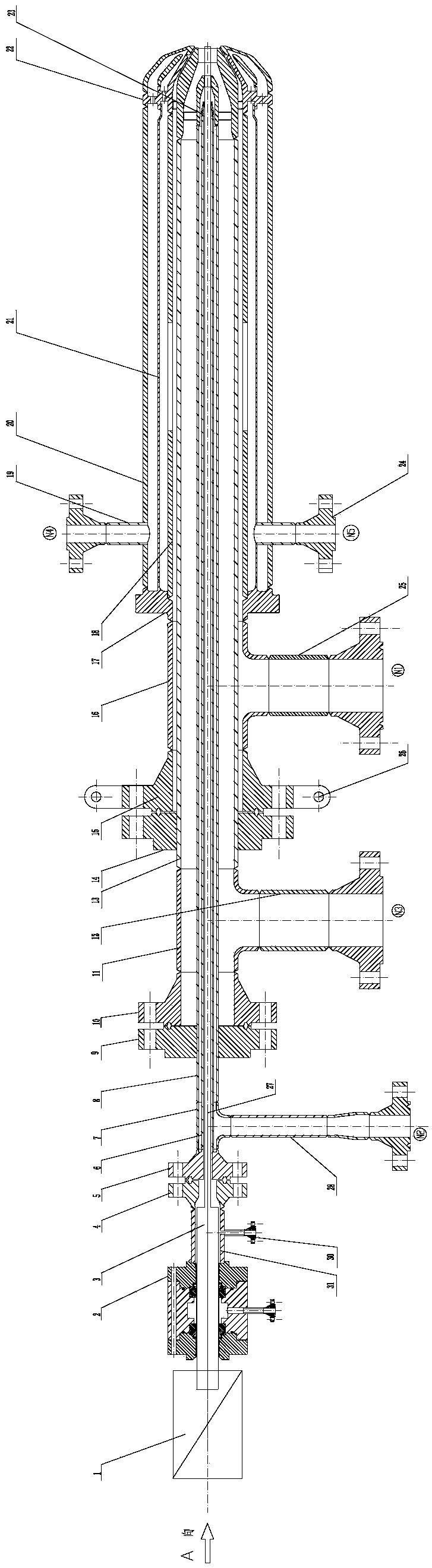

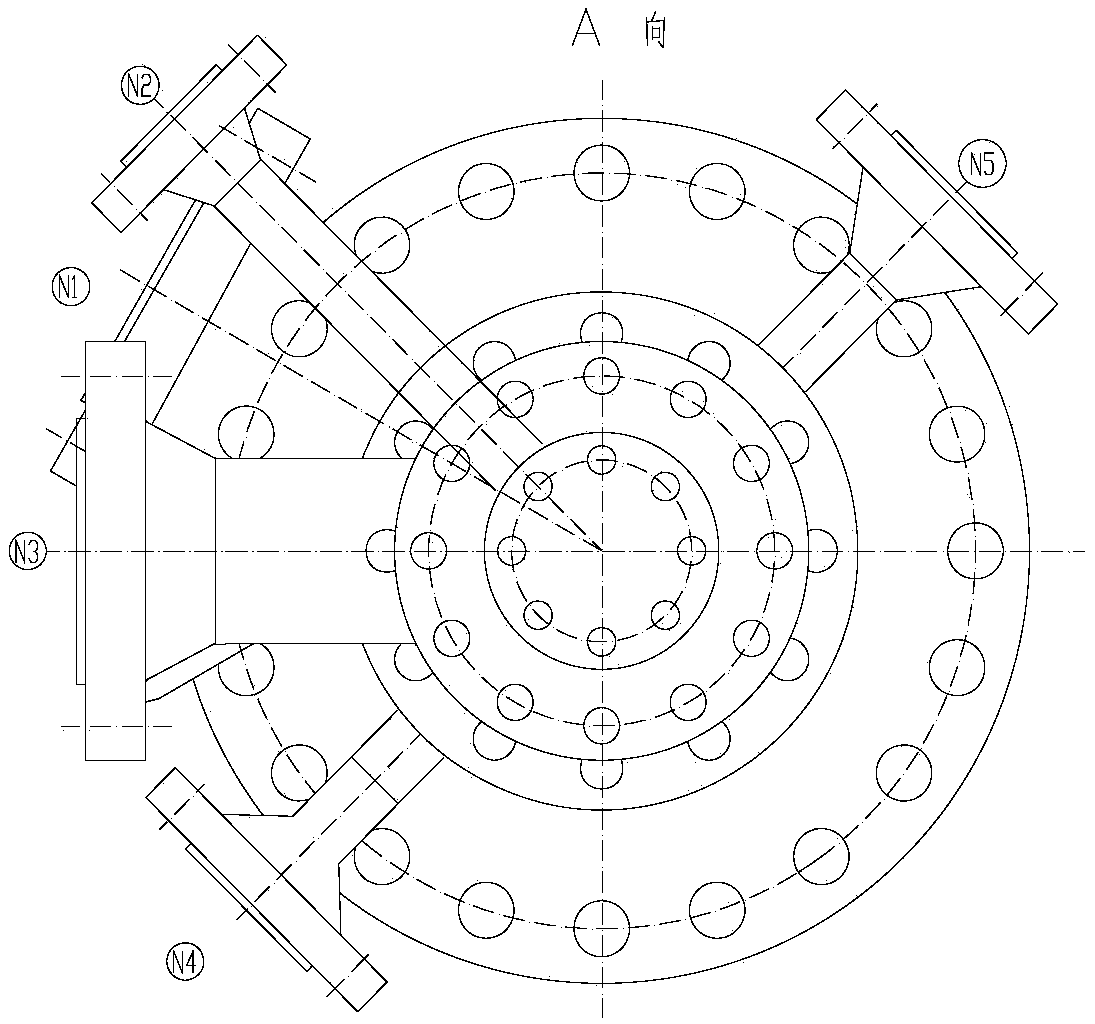

[0047] exist figure 1 Among them, the present invention is an integrated coal-water slurry burner, one end of the burner body is welded and fixed with a burner head, and the other end is welded and fixed with a third tee 16, and one end of the third tee 16 is connected with the outer epoxy oxygen inlet The pipeline 25 is connected, and the other end is welded and fixed to the sixth connecting flange 15 equipped with lifting lugs. The sixth connecting flange 15 and the fifth connecting flange 14 are fixedly connected and installed with threaded fastening connectors. The third three-way Insert the coal water slurry casing 13 in 16, the coal water slurry casing 13 is used to transmit the coal water slurry, one end of the coal water slurry casing 13 is connected with the burner head, and the other end is connected with the second three-way 11, the second One end of the two-way connection 11 is welded and fixed to the fourth connecting flange 10, and the other end is connected to t...

Embodiment 2

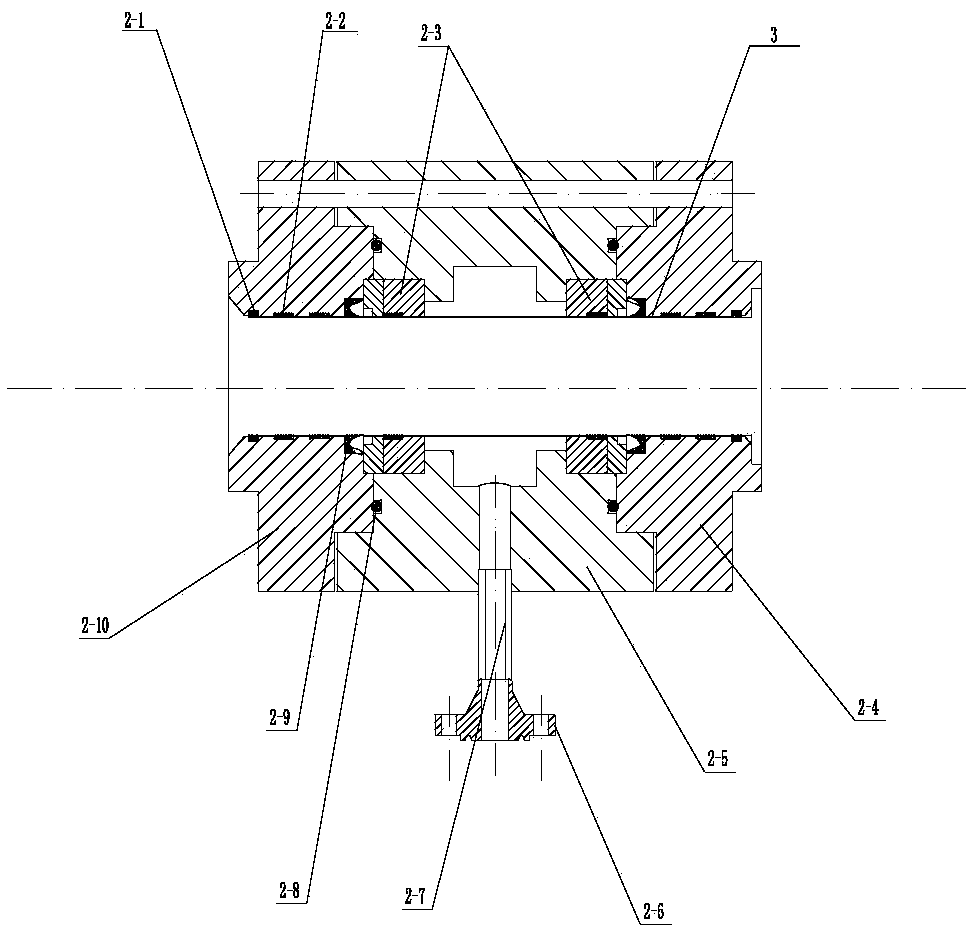

[0055] In the above-mentioned embodiment 1, the ignition gun conduit head 23 of the present embodiment is a conical structure, and 4 air holes are evenly distributed on the ignition gun conduit head 23, and the conical structure of the coal-water slurry nozzle 22-1 and the ring cover The conical structure of the connector 22-7 is concentric and forms an outer epoxy oxygen inlet channel with a spacing of 8 mm. The central oxygen inlet nozzle 22-6 is indented 8 mm from the end face of the head ring cover 22-4 to the fire end, and the coal water slurry The fire end of the nozzle 22-1 is indented by 1 mm relative to the end face of the head ring cover 22-4, and the upper part of the ring cover connector 22-7 is evenly distributed with 20 water outlet holes b and the water isolation ring 22 The lower part of -5 is uniformly processed with 20 inlet holes a, the diameter of the inlet hole a is 4mm, the diameter of the outlet hole b is 4mm, and the included angle between the water barr...

Embodiment 3

[0057] In the above-mentioned embodiment 1, the ignition gun conduit head 23 of the present embodiment is a conical structure, and 6 air holes are evenly distributed on the ignition gun conduit head 23, and the conical structure of the coal-water slurry nozzle 22-1 and the ring cover The conical structure of the connector 22-7 is concentric and forms an outer epoxy oxygen inlet channel with a spacing of 20 mm. The central oxygen inlet nozzle 22-6 is indented by 10 mm from the end face of the head ring cover 22-4 to the fire end, and the coal water slurry The fire end of the nozzle 22-1 is indented by 3mm relative to the end face of the head ring cover 22-4, and the upper part of the ring cover connector 22-7 is evenly distributed with 60 water outlet holes b and the water isolation ring 22 The lower part of -5 is uniformly processed with 60 inlet holes a, the diameter of the inlet hole a is 8mm, the diameter of the outlet hole b is 8mm, and the included angle between the water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com