Reworkable cross-linked weather-resistant polyolefin film for solar cell backsheets

A technology of solar cells and solar cells, applied in the direction of films/sheets, circuits, adhesives, etc. without a carrier, which can solve problems such as cell rupture and loss

Inactive Publication Date: 2022-02-08

NANYA PLASTICS CORP

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In actual processing, it is often found that after tearing off the solar cell back sheet, there is residual glue of the solar cell back sheet on the EVA because the bonding is too tight. Area cell rupture and other problems, causing great losses

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

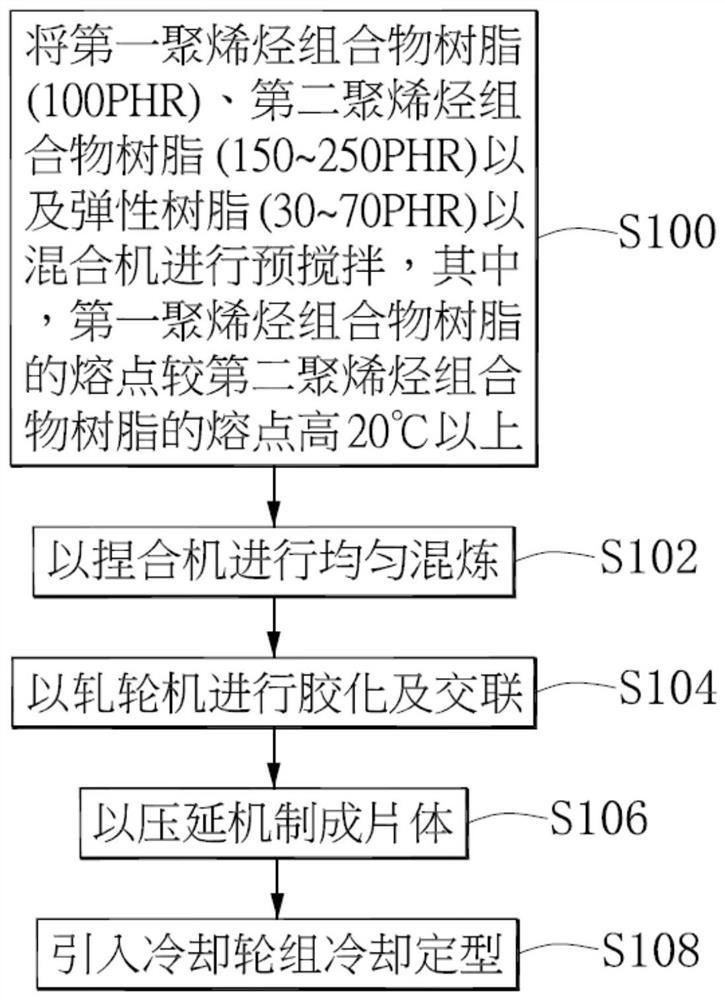

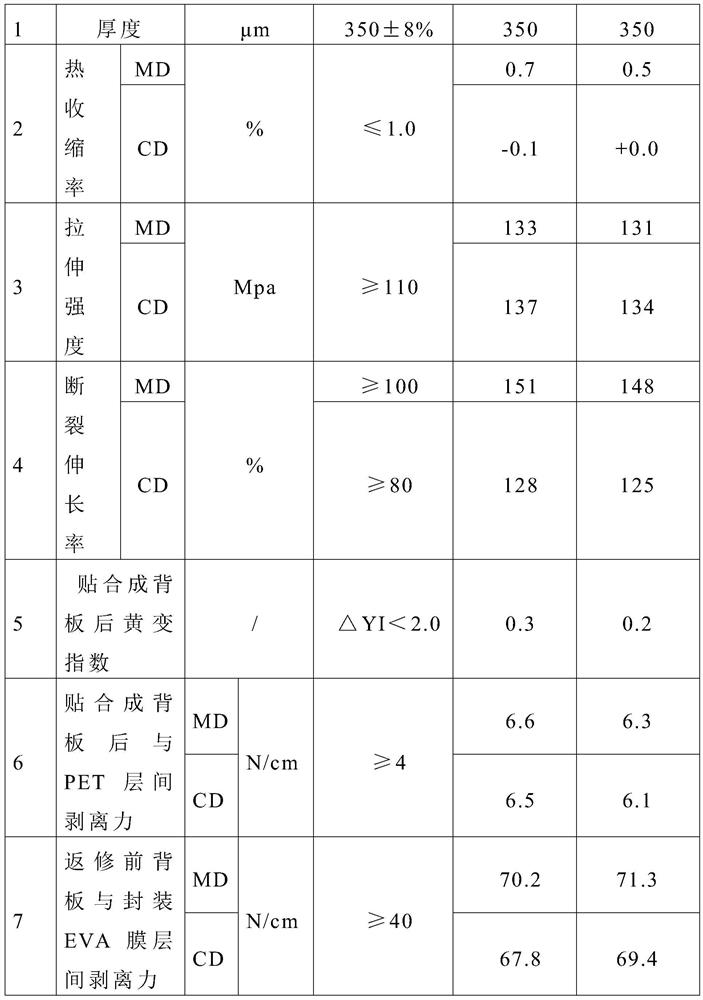

[0056] The ingredients according to Table 1 were withdrawn and added to the mixer. It is pre-stirred by a mixer at low temperature to form a mixture, which is kneaded by a kneader, and then sent to a rolling mill for gelation and cross-linking at a temperature of 175°C. Then, it was pressed into a sheet with a thickness of 0.06 mm by a calender at 210° C. at a rate of 105 meters per minute.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Login to View More

Abstract

A reworkable cross-linked weather-resistant polyolefin film, which comprises the following components: 100 parts by weight of a first polyolefin composition resin, 10-250 parts by weight of a second polyolefin composition resin, and 30-70 parts by weight of Elastic resin. The melting point of the first polyolefin composition resin is 20° C. or more higher than the melting point of the second polyolefin composition resin. The film of the present invention can be laminated with a solar cell module as a back sheet. When the film is torn off by heating, the film can be completely torn off due to the fact that the second polyolefin composition resin is slightly melted but the first polyolefin composition resin is not yet melted. In addition, the elastic resin can increase the viscoelasticity, so that the film can be completely removed from the battery module.

Description

technical field [0001] The invention relates to a reworkable cross-linked weather-resistant polyolefin film and a preparation method thereof, in particular to a reworkable cross-linked weather-resistant polyolefin film used for solar battery back plates and a preparation method thereof. Background technique [0002] Solar cell modules are mainly composed of glass cover plate, ethylene-vinyl acetate copolymer (EVA), battery sheet, back sheet, junction box and frame. Since the solar cell backsheet not only provides support and protection for the cells, but also is the packaging material most directly in contact with the external environment in a large area among the above-mentioned components, its performance directly affects the power generation efficiency and Therefore, the solar battery backplane has always been one of the very important and indispensable components in the solar battery module. [0003] Although in the production of solar cell backsheets, great attention i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09J7/10C09J7/30C09J123/08C09J123/06C09J123/12C09J127/12H01L31/048H01L31/049

CPCH01L31/0481H01L31/049C09J7/00C09J7/10C09J7/30C09J11/04C09J11/06C09J123/06C09J123/0815C09J123/0853C09J123/12C08L2203/204C08L2205/035C08K2003/2241C08K2201/011C08L2207/062C08L2207/066C08L2312/00C09J2423/04C09J2423/10C09J2427/00C08L23/0815C08L23/12C08L23/0853C08L27/16C08L27/18C08L27/12C08K3/22C08L23/06Y02E10/50

Inventor 盛修业

Owner NANYA PLASTICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com